MAGNETIC SEPARATION PULLEYS

Bunting® has an extensive line of Magnetic Separation Head Pulleys for conveyors in the Recycling Industry. These pulleys offer superior removal of ferrous contamination like nails, spikes, nuts, bolts, cans, and wire for conveyors in the paper, wood, plastic, steel and municipal recycling industries with maintenance free operation.

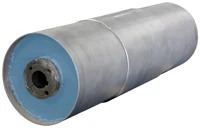

Magnetic Separation Head Pulleys are a way of continuously removing and discharging tramp metal from the product flow for both product purification and materials separation. If you are designing and building your own conveyors, Bunting® offers economical OEM Magnetic Ceramic Separation Pulleys or the optional high intensity Neo Rare Earth Pulleys for those critical separation jobs.

Magnetic Separation Pulleys are designed and manufactured for maximum reach-out, holding force and separation effectiveness. They are manufactured in both the economical Ceramic and the high intensity Neo Rare Earth for maximum separation. Magnetic Pulleys are even more effective when used in combination with overhead Magnetic Cross-Belt Conveyors on thicker burdens or more dense conveyed materials.

Installation: Bunting® Magnetic Separation Pulleys can be installed in the two basic configurations as shown. The first (1) is using the Magnetic Pulley alone which works fine in most installations. The second (2) is used in conjunction with a Magnetic Take-off Rail which helps convey the ferrous tramp back from the end of the conveyor and farther away from the clean product stream. This works especially well on the smaller pulley diameters but is very effective on all sizes.