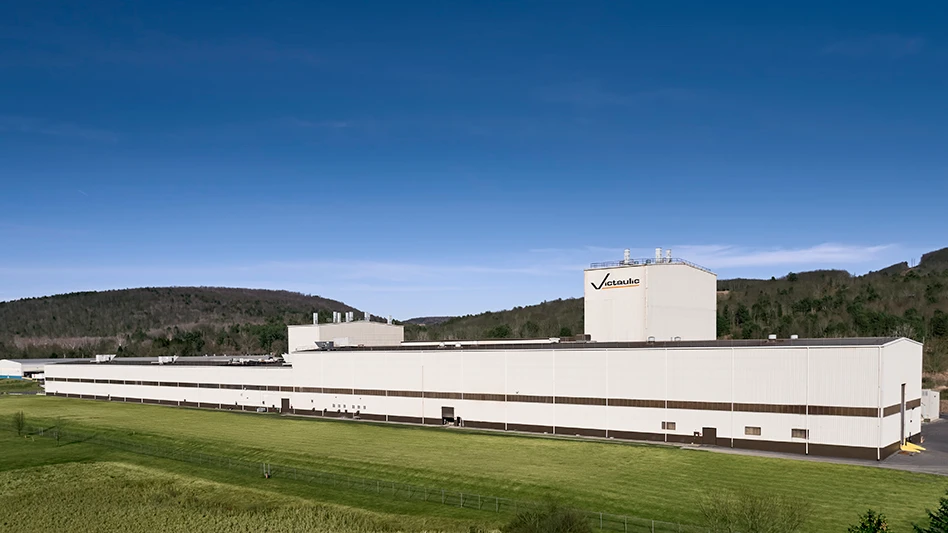

Photo courtesy of Victaulic Co.

Easton, Pennsylvania-based Victaulic Co. has announced plans for a $100 million expansion project to take place at the iron pipe producer’s foundry in Lawrenceville, Pennsylvania.

The expansion to the foundry is expected to increase Victaulic's production capacity and meet the demands of its North American customer base.

The expansion will create 214 new full-time jobs, adding to the more than 1,600 employees already working for Victaulic in Pennsylvania. Worldwide, Victaulic has more than 4,500 employees.

“This expansion underscores our unwavering commitment to creating family-sustaining jobs that positively impact our community,” Victaulic President and CEO Rick Bucher says. “The expansion will also bolster our manufacturing infrastructure, ensuring Victaulic remains the industry leader in producing high-quality, innovative solutions for the construction industry and our North American customers.

“The capital investment demonstrates our commitment to sustainable growth by incorporating production efficiency using the cleanest modern melting technology available. Victaulic takes pride in the fact that our solutions are manufactured using 100 percent recycled steel and are infinitely reconfigurable.”

Victaulic currently uses induction furnace, ladle metallurgy and casting technology in its melt shop, according to its website.

When complete, the 150,000-square-foot addition to the Lawrenceville foundry will host new molding lines, melt furnaces, core machines, automated finishing and paint equipment. The expansion will also include a 60,000-square-foot machine shop with what Victaulic calls state-of-the-art computer numerical control (CNC) equipment.

The office of Pennsylvania Gov. Josh Shapiro says the state is contributing $1.5 million to support the project in Lawrenceville, which is in Tioga County in the north central part of the state.

“With the support of the commonwealth, Victaulic is investing $100 million in Tioga County to expand its manufacturing capacity and create 214 new jobs,” Shapiro says. “Since day one, my administration has had a clear plan to double down on our investments in economic development so Pennsylvania companies like Victaulic can compete and win.”

Much of the funding received by Victaulic is tied to a proposal from the state’s Department of Community and Economic Development (DCED) for a $1.07 million Pennsylvania First Program grant. Another $428,000 comes in the form of a Workforce and Development Network grant to train workers.

Victaulic traces its roots to the 1919 filing of a patent by Ernest Tribe and Dr. Henry Hele-Shaw for what is now known as the Victaulic coupling, the concept of joining pipes with bolted mechanical grooved couplings, using a gasket seal. The manufacturer, originally known as The Victory Pipe Joint Co., was renamed Victaulic in 1925, which it says represents a combination of the words “victory” and “hydraulic.”

In addition to its Pennsylvania campus, Victaulic also operates foundries in China, Mexico and Poland. It says its products can be found in structures worldwide, including the Eifel Tower, the “Bird’s Nest” Beijing Olympic Stadium, the Hoover Dam and the Bellagio in Las Vegas.

Latest from Recycling Today

- BMW Group, Encory launch 'direct recycling’ of batteries

- Loom Carbon, RTI International partner to scale textile recycling technology

- Goodwill Industries of West Michigan, American Glass Mosaics partner to divert glass from landfill

- CARI forms federal advocacy partnership

- Monthly packaging papers shipments down in November

- STEEL Act aims to enhance trade enforcement to prevent dumping of steel in the US

- San Francisco schools introduce compostable lunch trays

- Aduro graduates from Shell GameChanger program