Universal Recycling Technologies (URT)

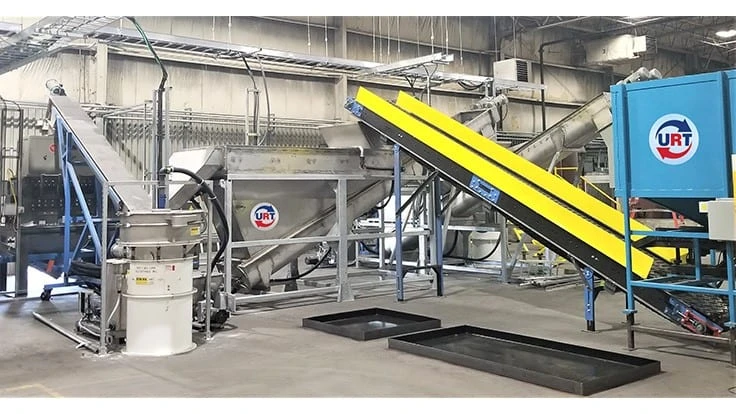

Universal Recycling Technologies (URT), Janesville, Wisconsin, has announced a new plastic separation and recycling system, designed for plastic electronic scrap.

URT says few electronic recycling companies focus on the recovery of plastics from their recycling processes. The company says this system allows URT to produce clean granulated product that can be sold domestically.

The plastic separation and recycling system uses multiple separation tanks and is designed to process 6,000 pounds of electronic plastic scrap per hour, while recovering 100 percent of all metal contaminants from the plastic stream.

The company says it is designed to separate targeted plastics by processing the material in a fluid of intermediate density. The material with a specific gravity higher than that of the intermediate fluid will sink while the other material with a lower specific gravity will float.

E-waste plastics account for a dozen or more different polymers and certain plastics contain flame retardants that need to be separated. URT says the system focuses on the recovery of the following plastics: polystyrene (PS), acrylonitrile butadiene styrene (ABS), polyethylene (PE) and polypropylene (PP).

URT began researching and investigating into a plastic separation system three years ago.

“We saw an opportunity in the market,” says URT President Jim Cornwell, “and wanted to provide a stable and domestic e-waste plastic solution for our customers.”

In 2019, URT says it built a prototype system that tested the design process and product valuation.

Due to changes in plastic export requirements listed in updated Basel treaty amendment standards, domestic solutions for e-scrap plastic recycling are top of mind for U.S. based processors.

Jeff Gloyd, URT’s vice president of sales, shares that the system, “allows URT to own our destiny related to plastics recycling. This helps us stabilize value, which, in turn, helps us better service our diverse base of customers."

Latest from Recycling Today

- Orion ramping up Rocky Mountain Steel rail line

- Proposed bill would provide ‘regulatory clarity’ for chemical recycling

- Alberta Ag-Plastic pilot program continues, expands with renewed funding

- ReMA urges open intra-North American scrap trade

- Axium awarded by regional organization

- Update: China to introduce steel export quotas

- Thyssenkrupp idles capacity in Europe

- Phoenix Technologies closes Ohio rPET facility