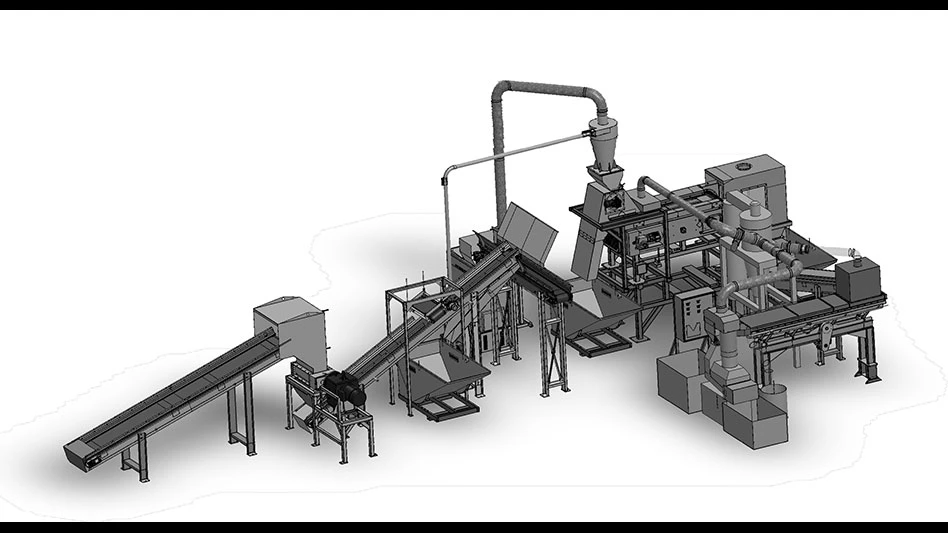

Photo courtesy of BCA Industries

Recyclers must swiftly adapt to prepare for the significant surge in LED lighting products as the global shift toward energy-efficient LED lighting is projected to grow at a compound annual rate of 11 percent from 2023 to 2030, according to Grand View Research. The challenge lies in recycling large volumes of used bulbs of varying sizes, shapes and diode densities. LED lighting manufacturers also must recycle defective products to reclaim valuable materials that can include gallium, indium and other metals from electronic chips, as well as glass and plastic. The gallium and indium can be separated by further downstream processing.

To maximize recycling yield, however, the key is to effectively dismantle intricate LED configurations and then efficiently separate them into valuable materials. This requires recyclers to adapt their processes and systems to cater to the distinct characteristics of LEDs, which differ from traditional incandescent and fluorescent bulbs in that they are a fusion of lighting and electronics, consisting of various components such as a chip, heat sink, circuit board/driver, housing, base and lens/optics, says John Neuens, an industrial consultant with BCA Industries, a Milwaukee-based developer and manufacturer of industrial shredding and recycling equipment.

a recycler with more than a dozen locations requested a

complete end-to-end system tailored to meet its needs.

“Recycling LEDs is an emerging form of electronics recycling that lacks a comprehensive system for effective material separation and plant environment control,” Neuens says. “There are unique challenges in the process, and few systems are specifically designed for both efficient recycling and the maximized extraction of saleable materials.”

He adds that companies manufacturing LED lighting also are looking to recover material from defective products.

Unfortunately, recyclers have encountered obstacles in achieving profitability and scale-up given their use of recycling systems not specifically designed for LEDs. As a result, the outcomes have been inconsistent and inefficient.

Neuens says a leading multilocation recycler reached out to BCA with the aim of enhancing the efficiency of its LED reclamation process. The equipment manufacturer responded by developing a system specifically designed for LED lights that separates and recovers the maximum amount of valuable material. After successful development and implementation, the system is now available to other recyclers.

The LED recycling system is engineered to maximize the precision and accuracy of separation, resulting in higher market value for the extracted materials, BCA says. The original system initially was intended to handle 1.5 tons of LED bulbs per hour. However, it has the flexibility to be tailored to any desired volume and customized to meet the specific mix of products received by the recycler.

“LEDs, while longer-lasting and more energy-efficient than other bulbs, still require effective recycling. Disposing even a small amount of recyclable materials in landfills should be avoided,” Neuens says.

The challenges of recycling LEDs

Efficiently recycling LEDs is an extremely complex process involving sequential mechanical reduction and separation. This entails not only cutting and crushing but also magnetic, electrostatic and gravity separation and classification.

To ensure workplace health and safety, it is crucial to have adequate environmental controls in place at every stage of the process. These controls should effectively manage and collect dust and other possible contaminants that could pose hazards.

The objective is to maximize the recovery of usable material, isolating it into the most saleable form. However, complex issues can arise when assembling and implementing systems such as these in a piecemeal manner. Problems frequently occur during installation and persist throughout production, leading to decreased efficiency, quality and profitability. If an issue arises, “finger-pointing” often occurs between multiple vendors, with each blaming the other, while the core issues remain unresolved.

Even hiring a third-party engineering company or integrator might not resolve the situation if those involved do not have a clear understanding of the design and functioning of the component parts. This understanding is crucial when reconfiguration or modification is required to accommodate the recycler's specific circumstances.

In the meantime, the recycler could experience a decrease in production or even a complete halt.

Optimizing LED recycling

To meet increased LED volumes and avoid such issues, a recycler with more than a dozen locations turned to BCA to design a complete end-to-end system tailored to meet its needs. LED-specific system that BCA designed for the recycler is comprised of various integrated equipment that functions in concert, Neuens says.

Initially, an infeed conveyor brings inoperable LED bulbs to a dual-shaft shredder. Next, a series of magnets recovers ferrous metals that otherwise could be trapped under other materials. The conveyed material is further reduced by a granulator, a single-shaft machine with a bed knife that crushes and cuts, and additional magnets are used to capture the finer ferrous material. An eddy current separator is then used to extract nonferrous metals such as copper and aluminum.

Other processes such as vibratory screening and density separation are used to extract additional valuable materials, including glass and plastics of varying weights.

Throughout the reduction and separation process, stringent environmental controls are implemented to capture minuscule dust particles, mitigating potential health risks. An air system specifically collects and filters out fine dust particles to protect worker health and essentially eliminate potential combustive risk.

For optimal results, additional adjustment or customization could be required based on the recycler’s specific location, process and expected LED volumes.

“To achieve greater volumes, modifying the shredder size is often necessary. However, from an engineering perspective, it can be challenging to precisely adjust, measure and accommodate the tonnage and quality of each material without a thorough understanding of the system. Several factors, including chamber size, rpms, variable frequency drives and software programming changes, come into play. This necessitates comprehensive system integration,” Neuens says.

BCA spent a month setting up, testing and fine-tuning the recycler’s LED processing system, making various adjustments and enhancements to customize it according to the processor’s specific requirements.

“These new systems are specifically built to efficiently recycle LEDs from initial feed to controlling the plant environment, all the way to producing the maximum amount of salable material, including ferrous metals, aluminum, copper, light plastic, heavy plastic and glass, when separation is complete,” Neuens says. “Most of the material we recover is an eighth of an inch to a quarter of an inch and can be recycled for use in other areas.”

One example is glass, which can be used in shot peening to clean and finish metals or other surfaces less aggressively than sandblasting.

Neuens says fully integrating the system to meet the recycler’s needs is also a top priority. To this end, the OEM conducted factory acceptance testing (FAT) to verify that newly manufactured equipment met its intended purpose, as well as site acceptance testing (SAT) to ensure that the system performed as required at the specific location.

“Recyclers want a complete, integrated LED material recovery system backed by a manufacturer’s warranty,” he says. “They want a single developer and one phone number to call to quickly resolve any problems.”

To minimize issues and expedite maintenance and training for those who purchase the LED recovery system, BCA offers comprehensive walk-through videos that provide detailed guidance. This helps to prevent the loss of critical knowledge that can occur when experienced personnel leave. Watching the tutorials also facilitates getting new employees quickly up to speed on using the equipment.

Neuens says the designers “walk through” every element of the machine and system, including operation, maintenance, safety and programming. They point out how to properly operate the equipment, what needs to be greased/oiled and what the fluid levels should be. They not only teach important safety tips but also what the software fault codes are and how to correct the issue.

“Our tutorial videos can be very specific, down to how to change knives, how to tune a machine and what to look for if a valve goes bad,” he adds.

As the use of LED lighting continues to grow, the need to efficiently accommodate the volumes of bulbs to be recycled only increases. Recyclers that quickly adopt fully integrated, LED-specific recycling systems will find that their fortunes will rise with the increased demand far into the future.

Del Williams is a technical writer based in Torrance, California.

Latest from Recycling Today

- Orion ramping up Rocky Mountain Steel rail line

- Proposed bill would provide ‘regulatory clarity’ for chemical recycling

- Alberta Ag-Plastic pilot program continues, expands with renewed funding

- ReMA urges open intra-North American scrap trade

- Axium awarded by regional organization

- Update: China to introduce steel export quotas

- Thyssenkrupp idles capacity in Europe

- Phoenix Technologies closes Ohio rPET facility