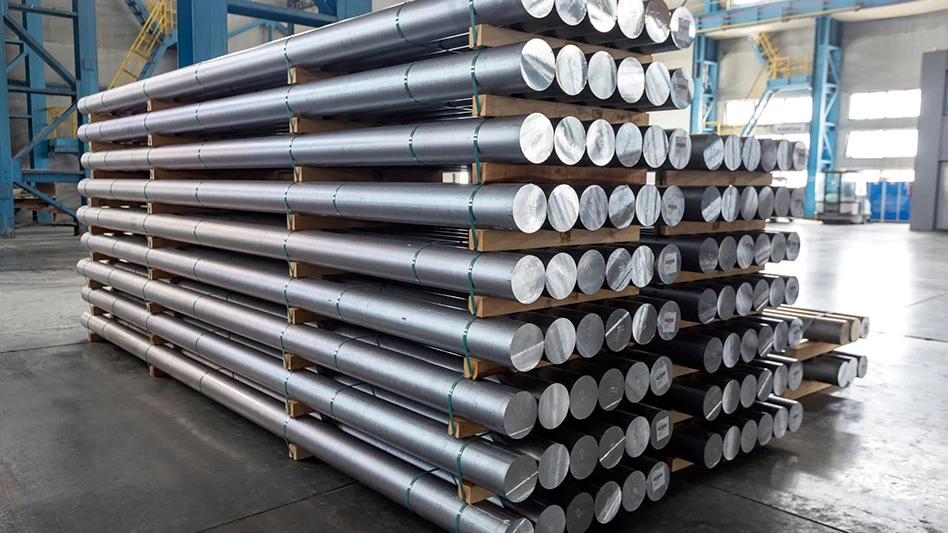

Photo courtesy of EMR

A research project led by EMR, a U.K.-based recycling company, has been supported by a 3.4 million pounds sterling ($4.3 million) grant from the U.K. government’s Advanced Propulsion Centre (APC). The funding will help support research into a facility to produce aluminum extrusion billet with less embodied carbon by using postconsumer scrap.

In addition to EMR, the project, ReCircAl, brings together key players in the supply chain: aluminum manufacturer and automotive tier 1 supplier Constellium, headquartered in Paris; academic metals center of excellence BCAST at Brunel University of London; advanced multidisciplined surface treatment expert BCW Treatments, Burnley, U.K.; and U,K.-based digital integration and rapid life cycle assessment specialists Riskoa, along with Stellantis, a multinational automotive manufacturer, which acts at the technical advisory group leader on the project.

ReCircAl brings together EMR’s knowledge and expertise in the industrial processing of end-of-life aluminum, with Constellium and Brunel University of London’s knowledge of alloy development, to deliver the lowest embodied carbon aluminum billets ever produced to provide a new benchmark in the industry.

Alongside EMR, Constellium plays a central role in the consortium, leveraging its extensive expertise in aluminum alloy development, which is crucial to the project’s success, with Constellium’s significant contributions to research and development being instrumental in delivering high-quality recycled aluminum products through the project.

The project will enable the creation of components made from up to 100 percent recycled aluminum at industrial scale, which will match the mechanical and durability performance of primary aluminum, EMR says.

The project builds on the Constellium-led CirConAl (Circular and Constant Aluminum) project, which also was sponsored by a 10 million pounds sterling, or $12.2 million, grant from the APC, and aimed to maximize the use of postconsumer scrap in a new generation of high-strength alloys that emit less than 2 tons of CO2 per ton of aluminum produced.

End-of-life aluminum will be processed within the consortium to provide a range of high-strength, impurity-tolerant billets for manufacturing structural automotive components, designed to meet or exceed the same quality and performance standards as those produced from primary-based materials and validated through rigorous qualification protocols established by the OEM partners.

“This project represents a landmark moment for the aluminum industry and the automotive sector,” says Bruce Miller, commercial director at EMR. “By proving that high-performance automotive components can be produced from recycled materials, we are helping to create a more circular vehicle manufacturing industry in the U.K.

“The support from the APC enables us to push the boundaries of what recycled aluminum can achieve,” he continues. “This collaboration will not only reduce the carbon footprint of U.K. manufacturing but also deliver significant economic benefits, securing future investment and jobs.”

Martin Jarrett, technology director of Constellium’s Automotive Structures and Industry business unit, says, “The APC-funded Constellium-led CirConAl project, together with the consortium partners, has pioneered the use of postconsumer scrap in a range of impurity-tolerant alloys providing the foundation for ReCircAl, which is aimed at developing the end-to-end recycled aluminum supply chain as a strategic resource for low-carbon aluminum production, creating a paradigm shift in the industry.”

“At BCW Treatments, we are proud to contribute our surface treatments expertise to a project that is transforming the aluminum supply chain,” adds Andy Wilson, Ph.D., BCW Treatments managing director. “By advancing the use of postconsumer scrap, we are helping to drive the transition to a circular economy, reducing carbon emissions and ensuring that high-performance materials can be sustainably sourced for future generations.”

Latest from Recycling Today

- BMW Group, Encory launch 'direct recycling’ of batteries

- Loom Carbon, RTI International partner to scale textile recycling technology

- Goodwill Industries of West Michigan, American Glass Mosaics partner to divert glass from landfill

- CARI forms federal advocacy partnership

- Monthly packaging papers shipments down in November

- STEEL Act aims to enhance trade enforcement to prevent dumping of steel in the US

- San Francisco schools introduce compostable lunch trays

- Aduro graduates from Shell GameChanger program