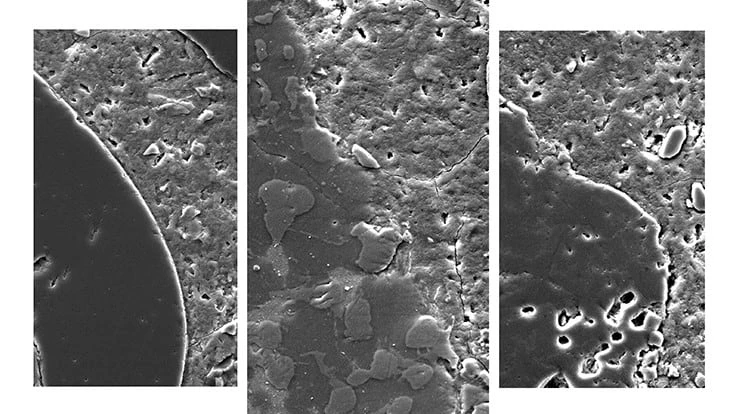

Image provided by RMIT University.

Researchers at RMIT University in Melbourne, Australia, say they have found two beneficial applications for slag, which is created as a byproduct of steelmaking, can be used consecutively.

The researchers say the byproduct can be used to both treat wastewater and to make stronger concrete, in what they call “a zero waste approach to help advance the circular economy.”

Produced during the separation of molten steel from impurities, steel slag often is used as a substitute aggregate material for making concrete, says the researchers.

Steel slag also can be used to absorb contaminants like phosphate, magnesium, iron, calcium, silica and aluminum in the wastewater treatment process, although in this application it “loses its effectiveness over time,” according to RMIT.

The engineering researchers at RMIT University examined whether slag that had been used to treat wastewater could then be recycled as an aggregate material for concrete.

The concrete made with post-treatment steel slag was about 17 percent stronger than concrete made with conventional aggregates, and 8 percent stronger than when made with raw steel slag, RMIT concluded.

Water engineer Dr. Biplob Pramanik said the study was the first to investigate potential applications for “sewage-enhanced” slag in construction material. “The global steelmaking industry produces over 130 million tons of steel slag every year,” he comments.

Adds Pramanik, “A lot of this byproduct already goes into concrete, but we’re missing the opportunity to wring out the full benefits of this material. Making stronger concrete could be as simple as enhancing the steel slag by first using it to treat our wastewater.”

He continues, “While there are technical challenges to overcome, we hope this research moves us one step closer to the ultimate goal of an integrated, no-waste approach to all our raw materials and byproducts.”

In the study, civil and water engineering researchers found the chemical properties of the slag are enhanced through the wastewater treatment, so it then performed well when used in concrete.

“The things that we want to remove from water are actually beneficial when it comes to concrete, so it’s a perfect match,” states Pramanik.

Civil engineer Dr Rajeev Roychand says the initial study was promising, but further research is needed to implement the approach on a larger scale, including investigating the long-term mechanical and durability properties of enhanced slag.

“Steel slag is currently not in widespread use in the wastewater treatment industry – just one plant based in New Zealand uses this byproduct in its treatment approach,” says Roychand.

He continues, “There is great potential here for three industries to work together – steelmaking, wastewater treatment and construction – and reap the maximum benefits of this byproduct.”

The full study, titled “Recycling steel slag from municipal wastewater treatment plants into concrete applications – A step towards circular economy,” by Roychand, Pramanik and RMIT School of Engineering co-authors Professor Sujeeva Setunge and Professor Kevin Zhang, can be found on this web page.

Latest from Recycling Today

- Lautenbach Recycling names business development manager

- Sebright Products partners with German waste management equipment company

- WasteExpo transitions to biennial format for enhanced experiences

- Study highlights progress, challenges in meeting PCR goals for packaging

- Washington legislature passes EPR bill

- PureCycle makes progress on use of PureFive resin in film trials

- New copper alloy achieves unprecedented high-temperature performance

- Gränges boosts profits and sales volume in Q1 2025