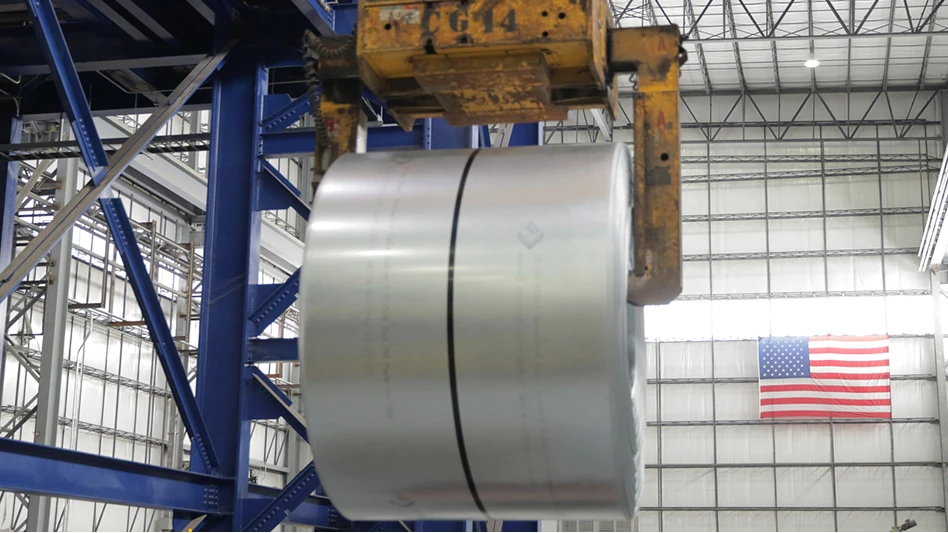

Photo courtesy of Steel Dynamics Inc. and Array Technologies

Albuquerque, New Mexico-based Array Technologies says it has reinforced what it calls a long-standing, 10-year partnership with Belding, Michigan-based Extruded Aluminum Corp. (EAC) to help expand Array’s manufacturing footprint with additional aluminum extrusion capacity.

The solar equipment supplier also has announced signing a long-term agreement with Fort Wayne, Indiana-based Steel Dynamics Inc. (SDI) to provide what Array calls “a fixed supply of coil for Array’s United States projects.”

EAC makes aluminum extrusion profiles, including structural fastening clamps, that Array says are “highly recyclable and contain recycled aluminum.” On its website, EAC lists several energy savings certificates it has received from Michigan-based scrap recycling firm Schupan.

States Array of its alliance with EAC, “This manufacturing collaboration underscores Arrays robust commitment to fostering a sustainable domestic supply chain while supporting economic development and job growth in Michigan.”

“Our relationship with EAC enhances our industry-leading capability to source in excess of 85 percent domestic content, the highest percentage in our sector,” says Kevin Hostetler, CEO of Array.

Array calls the collaboration with EAC part of a nearly $35 million dollar capital expansion by EAC, which includes adding 180,000 square feet to its existing facility and the addition of what the companies call “one of the largest aluminum presses in Michigan.”

“We are excited to fortify our long-term partnership with Array Technologies,” says Charlie Hall, CEO of EAC. “Our alignment in sustainable business practices, as well as our contribution to Array’s ever-strengthening U.S. supply chain, reflects our shared goals of industry leadership and commitment to renewable energy.”

Array says SDI will source the steel being provided from flat-roll steel mills in Indiana, Mississippi, and Texas. The agreement utilizes automation for efficiency and fosters local job growth, reinforcing Array’s commitment to strengthening U.S. manufacturing.

The solar technology company says SDI’s use of electric arc furnace (EAF) technology “produces lower-carbon emission, high-quality steel by using recycled ferrous scrap as the primary raw material.” Says Array of SDI, “Their circular manufacturing model aligns perfectly with Array’s sustainability goals, contributing to an environmentally responsible future while strengthening the U.S. supply chain.”

Array Technologies describes itself as a global provider of utility-scale solar tracker technology and software designed to maximize energy production.

Latest from Recycling Today

- Haber raises $44M to expand to North America

- Canada Plastics Pact releases 2023-24 Impact Report

- Reconomy brands receive platinum ratings from EcoVadis

- Sortera Technologies ‘owning and operating’ aluminum sorting solutions

- IDTechEx sees electric-powered construction equipment growth

- Global steel output recedes in November

- Fitch Ratings sees reasons for steel optimism in 2025

- P+PB adds new board members