Photo: Dreamstime

SPI: The Plastics Industry Trade Association, Washington, has introduced the Automotive End-of-Life Vehicles (ELV) Recycling Demonstration Project, which will test the belief that increased automotive recycling is beneficial to recyclers and the plastics industry. To make this program a reality, SPI is partnering with the Automotive Recyclers Association (ARA), Manassas, Virginia; Automotive Recyclers of Canada (ARC), London, Ontario; Canadian Plastics Industry Association (CPIA), Mississauga, Ontario, and a number of independent plastics and automotive recyclers. The goal of the ELV Recycling Demonstration Project is to develop a method of collection and recovery of polypropylene (PP) and thermoplastic Olefin (TPO) auto parts in a way that demonstrates technical and economic feasibility, SPI says.

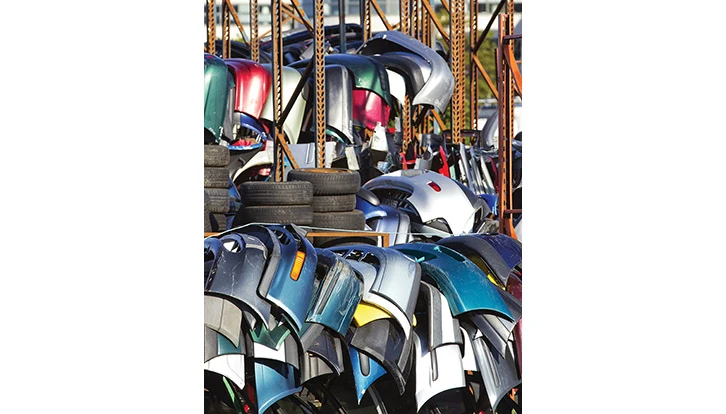

Approximately 12 million to 15 million vehicles are scrapped each year in the U.S. The average lifespan of a vehicle is estimated to be 11.5 years, and increasingly those vehicles are comprised of more and more plastics. Factors such as using plastic to lighten the weight of vehicles helps meet heightened Corporate Average Fuel Economy (CAFE) standards and the design freedom afforded by plastics are driving the increased use of plastics in new vehicle design, SPI says. Recovery of plastic components before shredding is largely driven by the resale market, but some recovery for mechanical recycling also is occurring.

“We want to make sure that our members see the business benefit of recycling automotive plastics,” says Kim Holmes, senior director of recycling and diversion at SPI. “The way to get real buy-in is to have concrete data that builds the business case for these recovery models.”

Another goal of the ELV Recycling Demonstration Project is to gather information to better guide design-for-recycling opportunities that can help inform future automotive design and recovery of plastics. “The automotive supply chain truly sees this as an opportunity to effect change on a number of levels, bringing meaningful change to the front and end of life,” says Kendra Martin, senior director of industry affairs at SPI.

Once gathered and analyzed, the project data and best management practices will be shared with the automotive and plastic recycling industries, SPI says. The goal is to predict trends in demand for recycled materials so recyclers can invest in processing capacity with greater confidence.

“As plastics continue to be a material of choice for vehicles due to their weight differences and other energy-efficient benefits, we are thrilled to play a leading role with SPI in a program and will continue to explore the benefits of recycling plastic automotive parts,” says Michael E. Wilson, CEO of the ARA.

Latest from Recycling Today

- Orion ramping up Rocky Mountain Steel rail line

- Proposed bill would provide ‘regulatory clarity’ for chemical recycling

- Alberta Ag-Plastic pilot program continues, expands with renewed funding

- ReMA urges open intra-North American scrap trade

- Axium awarded by regional organization

- Update: China to introduce steel export quotas

- Thyssenkrupp idles capacity in Europe

- Phoenix Technologies closes Ohio rPET facility