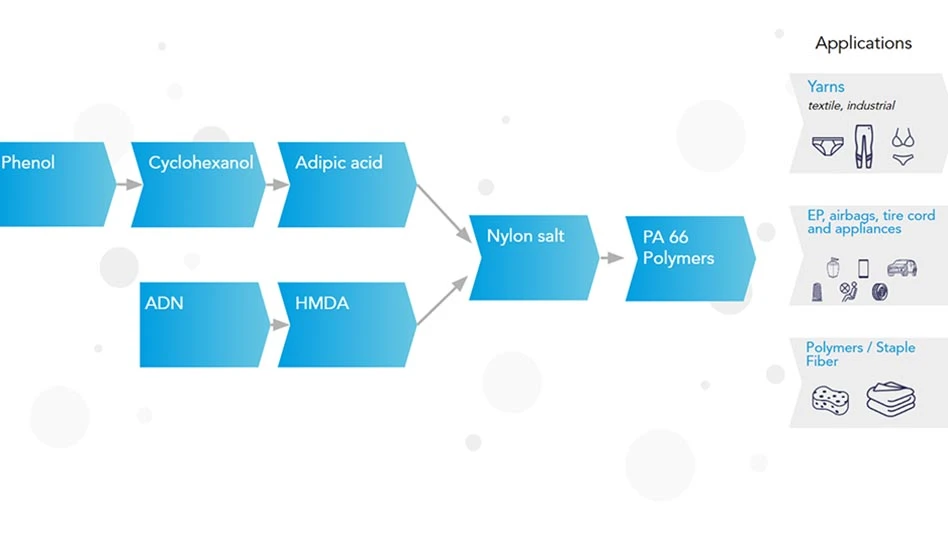

Graphic courtesy of Solvay

Brussels-based Solvay says its new grade of Rhodianyl polymer is made from 100 percent preconsumer-recycled polyamide scrap created at a chemical recycling facility in Brazil.

Solvay can now deliver a high-quality recycled polyamide (PA) 6.6 for the consumer goods and engineering plastic markets, citing a "groundbreaking and rigorously audited chemical recycling process."

The new specialized grade of Rhodianyl is being produced at Solvay's Santo Andre plant in Brazil, and the company notes it has received SCS Recycled Content Certification.

“With over 70 years of expertise, Solvay has strengthened its position as a leading producer and supplier of high-performance and sustainable PA66 polymers,” says Eduardo Girote, marketing director at Solvay.

“Certifying our recycling process is a significant step forward in meeting the stringent standards required by our European customers, who represent the primary market for this application due to the growing demand for recycled raw materials in the industry."

SCS Global Services performed an audit to verify the traceability of the group's entire manufacturing process, including scrap management and the depolymerization reaction, which generates the final 100 percent recycled polymer.

“Solvay’s commitment to producing 100 percent preconsumer Recycled Content Certified-polymer makes a positive impact on both the environment and the supply chain,” says Nicole Munoz, vice president at California-based SCS Global Services. “Using recycled content reduces waste, saves energy and gives materials a new life, rather than creating new materials."

Solvay says Rhodianyl can be applied in engineering plastics for the automotive, small appliances and textile markets and says the product launch is part of its ambition to reduce the environmental impact of its polyamide supply chain in Brazil.

That effort also has involved reducing CO2 emissions, biodiversity preservation on and near its campuses and launching a program for recycling polyamide uniforms.

Latest from Recycling Today

- Green Cubes unveils forklift battery line

- Rebar association points to trade turmoil

- LumiCup offers single-use plastic alternative

- European project yields recycled-content ABS

- ICM to host colocated events in Shanghai

- Astera runs into NIMBY concerns in Colorado

- ReMA opposes European efforts seeking export restrictions for recyclables

- Fresh Perspective: Raj Bagaria