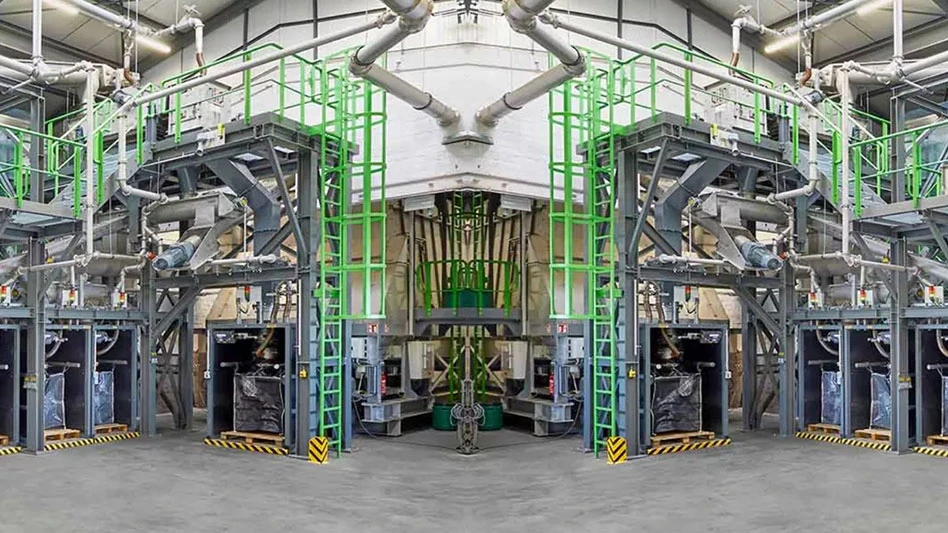

Photo courtesy of Redwood Materials

Redwood Materials, headquartered in Carson City, Nevada, has purchased lithium-ion battery recycler Redux Recycling GmbH, saying the acquisition will provide it with a well-established EU presence to quickly expand operations, increase capacity for battery recycling and work closely with established suppliers, customers and industry partners across Europe.

The company says Europe continues to be the fastest-growing electrical vehicle, or EV, market globally, driven by automakers commitments and strong government support to electrify. Redwood’s purchase of Redux Recycling supports this demand and further expands Redwood’s operations and commitment to the European market, where demand for battery recycling and materials manufacturing is growing rapidly.

Localizing the global battery supply chain across the U.S. and Europe are critical to driving down the costs and increasing the sustainability of electric vehicles and clean energy storage, Redwood says.

The Redux Recycling facility is in Bremerhaven, on Germany’s North Sea coast. It is equipped with 10,000 metric tons of annual processing capacity and can recycle many form factors and lithium-ion battery chemistries, according to Redwood. It can recycle EV and e-bike batteries, stationary storage systems and consumer devices such as cellphones, laptops and power drills. The facility is centrally located within Europe and near the Bremerhaven Port, one of the largest and most important import harbors for vehicles, allowing Redwood the ability to transport, recycle and refine electric vehicle packs and batteries from across the European continent.

With the acquisition, Redwood adds a team of about 70 technical staff, including chemical engineers, metallurgists and material scientists, to its existing team in Europe. The Redux team’s expertise in mechanical separation allows Redwood to recover high-purity metal concentrate, a critical input for battery materials production, according to the company. Redwood’s technology includes advanced material recovery processes, such as hydrometallurgy, which complement Redux's pretreatment and mechanical separation capabilities.

Redux's proprietary technology enables it to extract cobalt, lithium, nickel and manganese from end-of-life batteries with a recovery rate greater than 95 percent, Redwood says, complementing the high percentage recovery Redwood has accomplished in the U.S.

Latest from Recycling Today

- Biden officially blocks Nippon Steel’s acquisition of US Steel

- Highland Sanitation awarded solid waste and recycling contract in Wanamingo, Minnesota

- Ecobat gathers support for California permit renewal

- RecyclX platform designed to provide materials transparency

- Turkish mills sampled wide scrap market in 2024

- GLE Scrap Metal acquires interest in Mallin Cos.

- 2024 marks strong year for Van Dyk

- Recycled metal portrayed as former dictator’s fiefdom