Recycling Technologies, Swindon, United Kingdom, has been named the winner of three awards at the Rushlight Awards 2015-16 ceremony in late January 2016 in London. The Rushlight Awards, organized by Eventure Media and several energy and waste associations, focus on technology and innovation achievements made by British and Irish organizations and companies involved in efforts pertaining to sustainability and reducing carbon emissions.

Recycling Technologies was named winner of the Resource Recycling Award and the Resource Innovation Award in those two group categories as well as winning the broader Rushlight Award, presented to the overall winner of the night, deemed to have “demonstrated a substantial contribution to addressing environmental issues.”

“We are delighted to have won these awards and to have been recognized for our work transforming end of life plastic waste into a valuable hydrocarbon material,” says Adrian Griffiths, CEO of Recycling Technologies. “At Recycling Technologies, we are hugely proud of our process and genuinely believe that our work is a key innovation in the field of recycling plastic, creating a highly commercial, distributed solution for a global problem.”

Says Clive Hall of the Rushlight organization, “Innovation is a key driver for growth across our green economy and beyond, helping us find new ways to manage our environmental footprint, reduce costs and help put our businesses on a more sustainable footing. It’s great to see so many organizations stepping up to this challenge, and I would like to congratulate the winners of the Rushlight Awards on their exciting new ventures.”

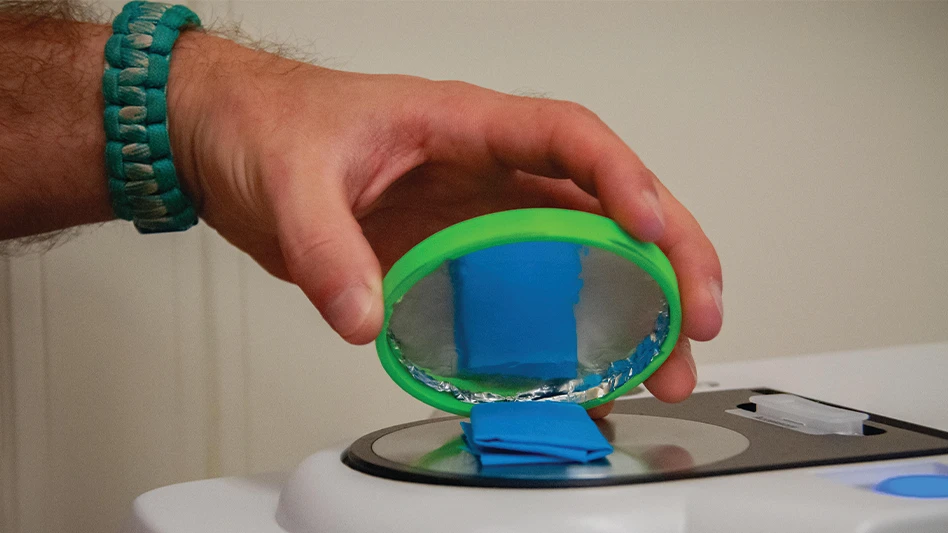

Recycling Technologies was formed in 2011 to commercialize the development of a plastic scrap energy conversion technique established originally by the University of Warwick in the U.K. The company’s flagship machine, the RT7000, converts unsorted residual plastic waste into what it calls a valuable low-sulphur hydrocarbon fuel oil known as Plaxx.

Latest from Recycling Today

- APR launches Recycling Leadership Awards

- Private equity firm announces majority investment in Sprout

- Author predicts spike in silver’s value

- SWANA webinar focuses on Phoenix recycling collaboration

- Domestic aluminum demand up through Q3 2024

- IntelliShift honored at IoT Breakthrough Awards

- Ace Green Recycling finalizes plans for battery recycling site in India

- Ambercycle, Benma partner to scale circular polyester