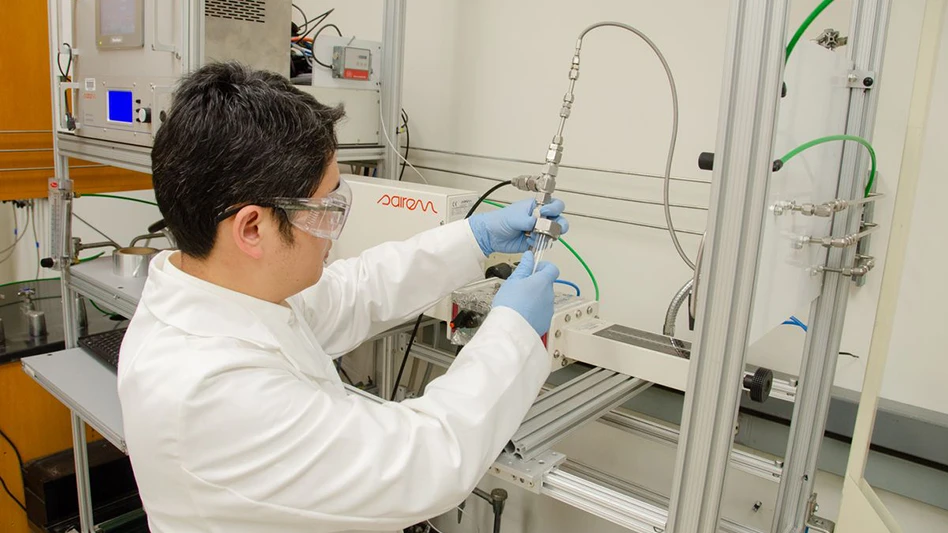

Photo courtesy of West Virginia University

Researchers at West Virginia University are exploring whether or how microwave technology can become an efficient way to extract market-ready propylene from polypropylene (PP) scrap.

The WVU Benjamin M. Statler College of Engineering and Mineral Resources in Morgantown, West Virginia, has accepted a $1 million grant from the Department of Energy to help fund WVU chemical engineer Yuxin Wang’s effort to use microwave technology to recover the chemical compound propylene from end-of-life PP.

“We need to diversify our strategies for dealing with America’s abundant plastic waste,” says Wang, an assistant professor at WVU. “Currently, polypropylene has a notably low recovery rate of only 1 percent, meaning 99 percent of polypropylene products become garbage. We want to change that by using microwave irradiation to recover propylene from polypropylene.”

“The world produces more polypropylene than any other plastic resin except polyethylene," WVU adds. "It’s found in kitchenware, sports equipment, bleach bottles, pipes, battery casings, medical devices, textiles and more.”

According to the research team, most PP products are single-use plastics, including to-go beverage cups. “Almost all of them eventually end up as trash, filling landfills or polluting the environment,” WVU says.

Wang is working along with Srinivas Palanki, chair of the Department of Chemical and Biomedical Engineering, to explore" energy-efficient approaches" to converting PP scrap back into propylene, which can be reused in new plastics or other products.

“We make 150.3 million metric tons of propylene every year through energy-intensive processes like ethane steam cracking," Palanki says. "These processes require very high temperatures. If we can recover usable propylene from [PP scrap], we’ll reduce energy and emissions throughout the life cycle of these plastics, and we’ll improve productivity and efficiency for U.S. manufacturers.”

According to WVU, many other researchers attempting to recover propylene from PP scrap have relied on thermochemical approaches such as pyrolysis, in which the material is heated in an oxygen-free environment. As characterized by Wang, PP thus far has largely resisted those efforts.

“The pyrolysis of PP typically results in a propylene yield of less than 25 percent, even with an optimized process,” Wang says. “Our challenge is to use microwaves to do it in a way that is cost competitive and can be practically implemented.”

Wang cites two advantages in using microwaves as an energy source: 1) microwave technology enables “precise and selective control” over the process, and; 2) it allows propylene recovery to happen at lower temperatures than in some thermal recovery processes—300 degrees Celsius (572 degrees Fahrenheit) compared with 600 or 700 degrees Celsius (1,112 to 1,292 degrees Fahrenheit).

In Wang and Palanki’s approach, microwave radiation is used to heat an intermediary catalyst material that then transfers that heat to the PP scrap. They say their technique is a form of “upcycling,” since it will break discarded material down into its original chemical components, which can then be used to manufacture a variety of products.

“In recycling, you crush a water bottle into small pieces and then use those pieces to build a bottle again,” says Wang. “Recycling limits your utilization. ... We want to generate chemicals that not only can be used to manufacture PP again, but also can be valuable in other reactions.”

Wang says the study also will expose WVU undergraduate and graduate students to resources of the Advanced Photon Source (APS) facility at the Argonne National Laboratory in Illinois.

“APS has cutting-edge technology that we will use in this project, and this is a great opportunity to build the relationship between our academic research program and a national lab,” he says.

As part of this study, students in Morgantown will be able to use new techniques developed at APS using Argonne’s synchrotron, a type of particle accelerator, according to Wang.

“The students will work with Argonne engineers like Tao Li, from Northern Illinois University, who’s an expert in the catalytic reaction processes we’re interested in,” Wang says. “They’ll learn plastic upcycling mechanisms and become part of the solution for our plastic waste issue.”

Latest from Recycling Today

- BMW Group, Encory launch 'direct recycling’ of batteries

- Loom Carbon, RTI International partner to scale textile recycling technology

- Goodwill Industries of West Michigan, American Glass Mosaics partner to divert glass from landfill

- CARI forms federal advocacy partnership

- Monthly packaging papers shipments down in November

- STEEL Act aims to enhance trade enforcement to prevent dumping of steel in the US

- San Francisco schools introduce compostable lunch trays

- Aduro graduates from Shell GameChanger program