The proverb “necessity is the mother of invention” can be tied to the origins of many recycling efforts, including those undertaken by The Paint Foundation, which is based in New York.

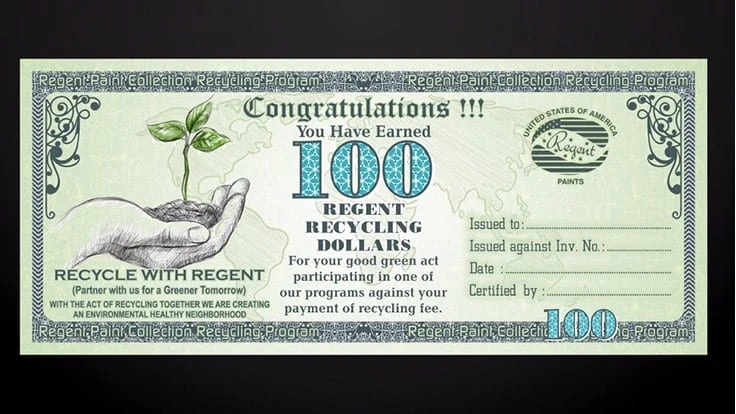

The foundation was created by Huzaifa Matawala, who is president of Glendale, New York-based Regent Paints USA Inc. That firm connects India and the United Arab Emirates (UAE) with the United States through its paint manufacturing and recycling activities.

Matawala says his origins in India prompted his attention to the repositioning of the millions of half-empty or one-quarter full paint cans either put in storage or discarded each year. Beyond such household generation, the paint industry itself and the paint retail chain can generate large amounts of discarded off-spec or expired coatings.

“Coming from a background in a non-oil rich nation, and with paint the result of combinations of petrochemicals, scarcity was a prime motivation for our inventions,” says Matawala. “Even before the growing sustainability movement, we reused, recycled, and had an upper hand competing in our markets,” says Matawala of Regent’s paint recycling activities.

The Paint Foundation has allowed Matawala and Regent to spread this philosophy of reuse and recycling beyond its own commercial needs. He says the activity has many benefits.

“Our work reduces pollution by diverting ‘waste’ paints from landfill or burning,” states Matawala. “Fuel incineration burns valuable ingredients, recycling reutilizes it. Paints stay alive for use again.”

A chain with several links

The foundation diverts and collects paint from many sources, he says. “Paint factories, paint raw-material industries, contractors, homeowners, counties, municipalities and recycling companies all accumulate a variety of paints,” says Matawala. “Our programs are so accurate and practical that they can keep millions of gallons of paints out of the waste stream.”

Paint comes in numerous varieties, which means the experience and knowledge of Matawala, Regent Paints staff members and others affiliated with The Paint Foundation quickly comes into play.

“Recycling paints is possible only with a detailed study of ingredients, chemistries, and properties,” says Matawala. “We set up processes and programs of reuse based on expertise. We create products of use and bring them back into the market that is used at affordable prices. We create quality products that can be used just like virgin paints.”

Matawala and others involved in The Paint Foundation take part in an industry that is far from static, he says. “We are third generation paint manufacturers. Paint is our family business and is, in fact, a part of the family now. We have seen times when glue and starch were resins, lime coats and powders were cooked with oils and thinned down with kerosene; times when linseed oils, turpentine and varnishes were used extensively. Then the phase of water-based acrylic emulsions took over, and then the phase of short oils, two-packs and metal-based high-performance coatings. Finally, now we have bio-based and recycled paints as the latest trend.”

States Matawala, “We have produced all of the above kinds of paints and their resins. The industry has traveled time in certain parts of the globe, but we have all phases of paints co-existing.”

While proud of his extensive experience and knowledge, Matawala says the work of The Paint Foundation has been a team effort. “Teaming up with R&D professionals, scientists, plant managers, and production supervisors, the effortless recycling concept became a natural format for producing quality products. Production formulations, presence of mind, applying chemical knowledge in everyday batches has brought us closer to perfection.”

The spice of life

The many varieties of paint available has likewise meant both Regent Paints and The Paint Foundation can offer an equally wide number of coatings.

“We produce several coatings, paint raw materials, and recycled intermediary items,” says Matawala. “We are able to produce recycled paints for almost all of several items we have created. We have patents in process with the United States Patent and Trademark Office (USPTO) for our processes and formulations for 13 recycled paint formulas. We produce about 53 recycled items that are useful for interior/exterior walls, steel construction coatings, different types of putties, waterproofing chemicals, wood coatings, high-performance industrial coatings, texture paints and road/bitumen products.”

Getting from collection to resale involves four stages, says Matawala: sorting, bulking, filtering and blending.

“In each stage, we create proprietary features that are directed toward the motive of the organization,” says Matawala. “The program for a paint collecting recycling company would be different from the paint factory. For the paint recycling business, we would design a totally different format of processing. We undertake a total project from designing, to recycling to receiving the items recycled and putting them back into the economy.”

There can be challenges at all stages, he says. “We make mistakes, but we try to never repeat the same mistake again,” remarks Matawala. “We have had paint batches solidifying, separations, gelled type formations, thinning, thickening, settling, losing properties and so much more. Dealing with huge variables within a wider spectrum of imperfections is an unavoidable routine.”

The rewards, he says, have much to do with sustainability. “We influence over 21 million kilograms [46.3 million pounds] of paint away from land burials and fuel blending, and back into the circular economy annually,” states Matawala.

“We took a social leap moving forward with this business by forming the not-for-profit charity foundation,” he continues. “This accelerates value several times to the industry by now providing them tax benefits as a donation for putting non-usables to use for reworking to the foundation. Disposal becomes donations, and such recreated/recycled paints will benefit communities of need.”

In addition to “reducing raw materials inputs and end-use disposal issues,” Matawala says The Paint Foundation helps by “creating employment, economic, climatic, and social advantages in the process. We give opportunities to paint industry personnel to join the foundation and contribute experience, expertise, knowledge, time and guidance for future growth, opening a wider spectrum to serve.”

Concludes Matawala, “In the era of abundance where the procurement of new raw materials is so easy, where access to resources and exploitation of nature is an all-time high, recycling will save us from deforestation, reduction in carbon footprint and bring us cleaner air, water and land.”

When it comes to the practice of recycling paint rather than disposing of it, he says the foundation is a way of providing “a systematic approach by, firstly, creating awareness, then educating, and finally collaborating by offering a total package that includes setting up recycling operations and picking up the material continually from locations.”

Latest from Recycling Today

- Aqua Metals secures $1.5M loan, reports operational strides

- AF&PA urges veto of NY bill

- Aluminum Association includes recycling among 2025 policy priorities

- AISI applauds waterways spending bill

- Lux Research questions hydrogen’s transportation role

- Sonoco selling thermoformed, flexible packaging business to Toppan for $1.8B

- ReMA offers Superfund informational reports

- Hyster-Yale commits to US production