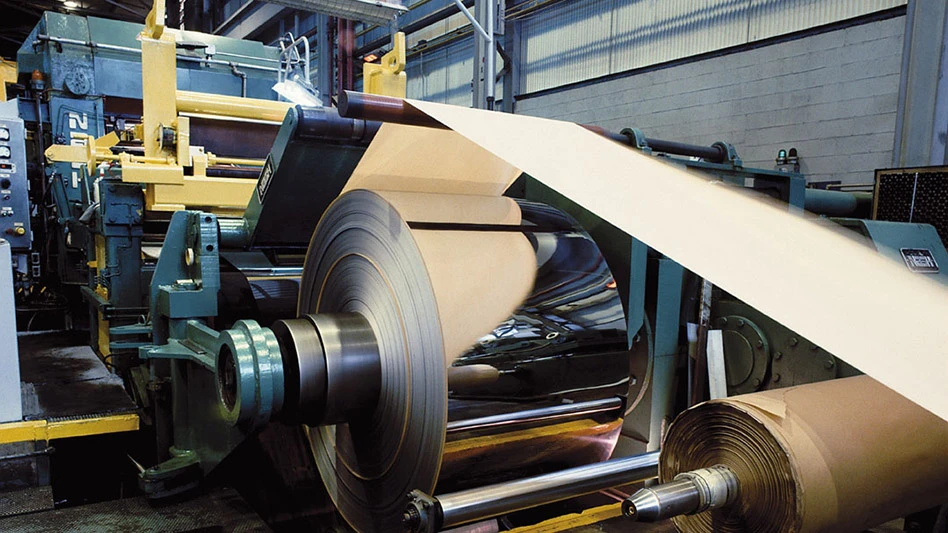

Photo courtesy of Nucor Corp.

Steel manufacturer Nucor Corp., Charlotte, North Carolina, has announced that it has made an equity investment in Boulder, Colorado-based Electra, a startup developing a process to produce carbon-free iron that can be used to make steel.

According to Nucor, Electra uses renewable energy to refine low-grade iron ores into high-purity iron through electrochemical and hydrometallurgical processes. This material can then be used in the steelmaking process to offset other high-quality metallics that come with higher greenhouse gas emissions.

Nucor says Electra’s process produces low-temperature iron (LTI) from commercial and low-grade ores using zero-carbon intermittent electricity. The company electrochemically refines iron ore into pure iron at 60 degrees Celsius (140 degrees Fahrenheit) using renewable electricity. That iron can be turned into steel using existing electric arc furnaces (EAFs), which Nucor says account for 70 percent of steel production in the U.S.

Nucor adds that Electra’s process results in zero carbon dioxide emissions. By comparison, around 70 percent of the steel produced globally is made with blast furnace technology, an extractive process fed by iron ore, coal and limestone that emits about two tons of carbon dioxide for every ton of steel produced.

“We are excited to partner with Electra and its revolutionary process to produce emission-free iron,” Nucor Chair, President and CEO Leon Topalian says. “Just as Nucor changed the face of the steel industry 53 years ago with our first electric arc furnace, successfully developing and scaling up a zero-carbon iron product is the type of transformative technology that could change the steel industry as we know it.”

Using primarily recycled scrap as raw material, Nucor says it is already one of the cleanest steelmakers in the world and that the circular nature of remelting recycled scrap in EAFs, combined with steel’s ability to be infinitely recycled, means the company’s steelmaking facilities generate roughly one-third of the carbon dioxide of extractive steelmaking plants. The investment in Electra is one of several Nucor is making that it says furthers its status as a sustainability leader and builds on the innovation that has already led to cleaner steel production in the U.S.

“We are focused on investing our capital on opportunities like these that have the potential to take our company and the entire industry to the next level,” says Doug Jellison, Nucor executive vice president of raw materials and a member of Electra’s market advisory board. “We will continue to look to the future for new and innovative ways to help our customers achieve their sustainability goals.”

Latest from Recycling Today

- MBA Polymers UK offers ABS to global market

- Tariffs likely rising on inbound steel, aluminum and copper

- CMC suffers losses in late 2024

- Nonferrous recyclers: Where do you rank?

- DTG Recycling faces $3.3M penalty from Washington Utilities and Transportation Commission

- Nippon, US Steel respond to Biden’s prohibition against US Steel purchase with lawsuits

- Recycling Today Media Group's battery recycling conference relocates in 2025

- IP amends DS Smith takeover bid