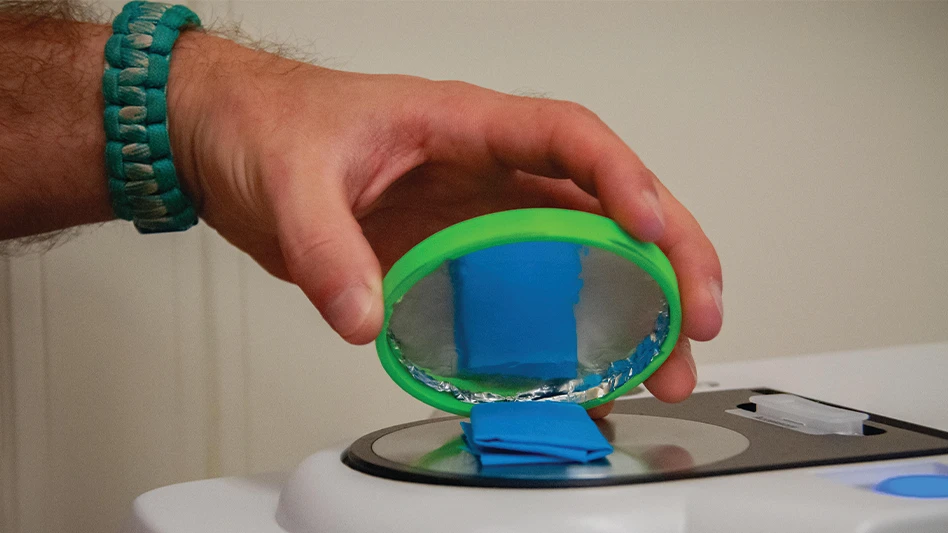

Photo courtesy of the National Institute of Standards and Technology

Researchers at the National Institute of Standards and Technology (NIST) have developed a database containing the molecular “fingerprints” of different kinds of textile fibers, which the Gaithersburg, Maryland-based branch of the U.S. Department of Commerce says can enable more rapid, efficient sorting of fabrics at recycling facilities.

NIST's database is free and available to download at the NIST Public Data Repository, and was developed to help solve the problem of textiles making their way to landfills. The organization cites U.S. Environmental Protection Agency (EPA) data from 2018 claiming 85 percent of used clothes and textiles headed to landfills in part because recycling can be more expensive than landfilling, providing companies little incentive to recycle.

“This reference data will help improve sorting algorithms and unlock the potential for high-throughput sorting, which requires less manual labor,” says Amanda Forster, a NIST materials research engineer who leads the project focused on textile circularity. “That should reduce costs and increase efficiency, making textile recycling more economically viable.”

NIST says textile scrap has grown in recent years for a number of reasons, including the popularity of fast fashion, the development of new types of textiles, blended textiles and incomplete or inaccurate labeling that can pose sorting and recycling challenges. At some recycling facilities, NIST says workers sort clothing using handheld near infrared (NIR) spectroscopy devices to identify the type of fibers in the clothing, and the technique also can be used in automated conveyor belt systems, though currently it requires a lot of manual labor.

NIST notes that in recent years, recycling equipment manufacturers increasingly have used machine learning and artificial intelligence (AI) to improve their sorting algorithms, and to train those algorithms they need high-quality reference data.

NIST’s database is designed to aid that process. Using its Near-Infrared Spectra of Origin-defined and Real-world Textiles, or NIR-SORT, it contains 64 different fabric types along with the NIR fingerprints they produce. The database includes pure fiber types, such as cotton and polyester; blended fiber types such as spandex blends; and real-world fabrics taken from thrift stores. NIST says manufacturers of NIR scanner systems can use its database to train and test their sorting algorithms and improve the performance of their products.

“The difficulty comes in when fibers are similar, like cotton or hemp,” says NIST research chemist Katarina Goodge, who led the development of the database. “That means that the near-infrared signal is similar. The same is true with a cotton and polyester blend. Is this a new fiber or a blend of two or more fibers? AI can help make the decision-making process more accurate.”

Because it is the nation’s measurement institute, NIST says it has the equipment and expertise to fill the database with high-quality spectra, which could lead to fewer errors when identifying fabrics and more textile recycling.

NIST's research stems from an initiative in which experts recommended the development of better technology for identifying and sorting textiles and clothing. The efforts are part of NIST’s Circular Economy Program, which develops measurement science and methods to support an economy where materials are designed to retain their value through repeated reuse, repair and recycling, with disposal as a last resort.

Latest from Recycling Today

- Phoenix Technologies closes Ohio rPET facility

- EPA selects 2 governments in Pennsylvania to receive recycling, waste grants

- NWRA Florida Chapter announces 2025 Legislative Champion Awards

- Goldman Sachs Research: Copper prices to decline in 2026

- Tomra opens London RVM showroom

- Ball Corp. makes European investment

- Harbor Logistics adds business development executive

- Emerald Packaging replaces more than 1M pounds of virgin plastic