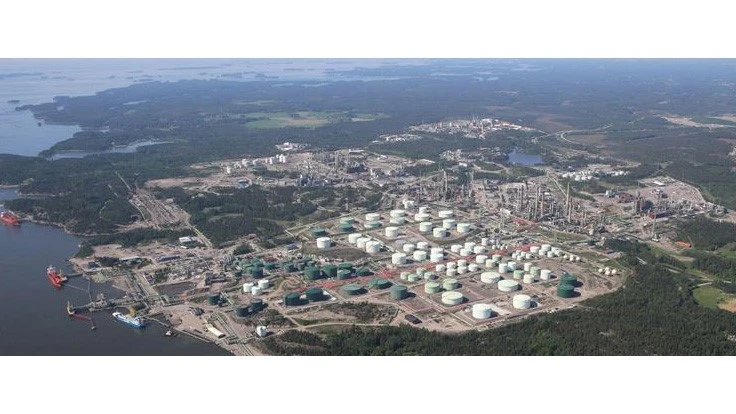

Photo courtesy of Neste Oyj

The potential of a prolonged absence of Russian oil and natural gas imports has Neste Oyj exploring the sustainable and circular options at its refining complex in Porvoo, Finland.

Neste, a Finland-based company, says it has launched a strategic study on transitioning its refinery in Porvoo to “noncrude oil refining and into a globally leading renewable and circular solutions site.”

In Singapore, Neste has invested in a project that converts plastic scrap and other byproducts into diesel fuel, aviation fuel and renewable polymers and chemicals. A $1.5 billion refinery expansion project there, announced in 2018 and scheduled for completion next year, involves boosting the refinery’s output from 1.3 million metric tons of annual output to 4.5 million metric tons.

In Porvoo, Neste says its study is exploring a conversion project away from fossil fuels that would “start with the co-processing of both renewable and circular feedstock and could continue with retrofits of existing units at a later stage, with a long-term capacity potential of 2 to 4 million metric tons per year.”

The company adds, “The targeted transformation would lead to a discontinuation of crude oil refining in Porvoo in the mid-2030s.”

“Neste’s growth strategy is centered on renewable and circular solutions," Neste President and CEO Matti Lehmus says. "We continue to set our ambition level high, launching this study on the long-term transformation path for our Porvoo refinery and targeting to ultimately replace crude oil with alternative feedstocks. The Porvoo site provides a flexible and large-scale base that can grow into a major site for our renewables and circular business."

The company already describes itself as “the world’s leading producer of sustainable aviation fuel and renewable diesel and developing chemical recycling to combat the plastic waste challenge.”

The company continues, “We are introducing renewable and recycled raw materials such as liquefied waste plastic as refinery raw materials. We have committed to reaching carbon-neutral production by 2035, and we will reduce the carbon emission intensity of sold products by 50 percent by 2040.”

Latest from Recycling Today

- SWANA webinar focuses on Phoenix recycling collaboration

- Domestic aluminum demand up through Q3 2024

- IntelliShift honored at IoT Breakthrough Awards

- Ace Green Recycling finalizes plans for battery recycling site in India

- Ambercycle, Benma partner to scale circular polyester

- NIST database aimed at increasing textile recycling

- ILA, USMX announce tentative agreement

- Innventure subsidiary acquires rights to advanced plastics recycling technology