Nashville, Tennessee-based MSS Inc., a manufacturer of optical sorting equipment, has announced that it recently achieved the highest average sorting performance against five competitors in an independent study. The results of this study were presented at the APR (Association of Plastics Recyclers) Technical Forum in New Orleans, Feb. 1, 2016.

The test sought to determine whether a new type of polyolefin-based shrink label for polyethylene terephthalate (PET) bottles, manufactured by UPM Raflatac, headquartered in Finland, could be commercialized in the current PET market using existing recycling infrastructure. The test also determined whether the labels could be separated properly by resin and by color.

The test sought to determine whether a new type of polyolefin-based shrink label for polyethylene terephthalate (PET) bottles, manufactured by UPM Raflatac, headquartered in Finland, could be commercialized in the current PET market using existing recycling infrastructure. The test also determined whether the labels could be separated properly by resin and by color.

This testing was facilitated and performed by Plastics Forming Enterprises LLC, Amherst, New Hampshire, an independent full-service testing and R&D company serving the plastics, packaging, recycling and consumer products industries.

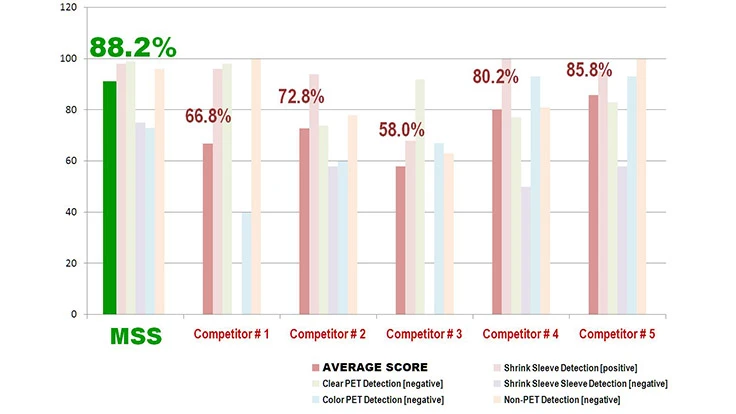

The evaluation was carried out at the testing centers of six optical sorter manufacturers. The testing involved several trial runs of sample bottles, as well as other runs of sample bottles mixed with random PET and non-PET plastic bottles, MSS reports.

The testing focused on the identification of PET bottles of various colors behind partially or fully sleeved labels of various colors and whether they could be positively or negatively sorted as separate categories.

The MSS Cirrus achieved the highest average test score (88.2 percent) amongst the six optical sorter manufacturers.

"This study further underlines that the MSS proprietary Cirrus NIR (near infrared) + color sensing and identification hardware and software are superior to other technologies, including NIR cameras and channelized scanners," says Felix Hottenstein, MSS sales director. "And it does apply to flake sorting applications as well."

Greg Thibado, MSS vice president, says, "The CIRRUS® is MSS’ latest generation of high-resolution NIR, color and metal sensor technology. This technology allows MSS to offer solutions for some of the toughest sorting requirements.”

The full report and presentation of the results in PDF format are available upon request.

MSS is a division of CP Group, San Diego. CP Group designs and manufactures material recovery facilities and recycling equipment for single-stream recycling, construction and demolition waste, commercial and industrial waste, waste to energy, municipal solid waste, electronic scrap, auto shredder residue and more.

Latest from Recycling Today

- Mixed paper, OCC prices end year on downward trend

- Updated: CAA submits final draft program plan in Oregon

- Enviri names new president of Harsco Environmental business

- Survey outlines ‘monumental challenge’ of plastic packaging collection in UK

- Nippon Steel acknowledges delay in US Steel acquisition attempt

- BASF collaborates to study mechanical plastic recycling

- Commentary: navigating shipping regulations for end-of-life and damaged batteries

- Haber raises $44M to expand to North America