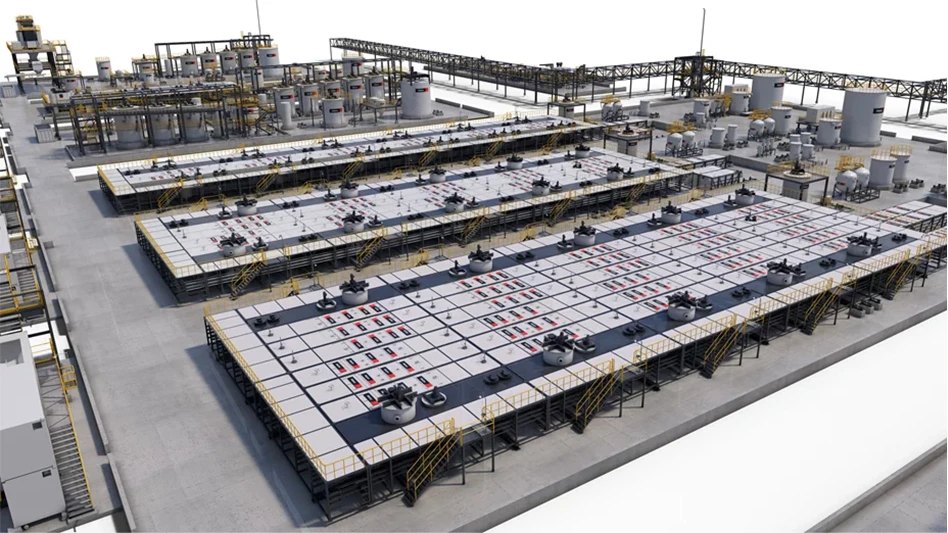

Rendering courtesy of Metso Oyj

Metso Oyj says its newly introduced black mass recycling technology has been designed to support the circular economy and respond to growing battery minerals demand.

Battery black mass recycling is becoming an important means to complement virgin battery metals supply and to reduce the carbon footprint of the battery supply chain, the Finland-based equipment and processing technology provider says.

Metso says its new battery black mass recycling process complements the company’s existing line of battery minerals technology offerings, which offers concentration and hydrometallurgical processing systems.

“The demand for battery minerals is increasing sharply with the ongoing transition to clean energy sources,” says Don Simola, director of battery chemicals technology at Metso. “For example, an electric car battery weighs approximately 200 kilos [441 pounds] and is made of several metals.

“To cater for this demand, the world will need to produce more minerals and metals, but we also need to strive to close the loop and extend the life cycle of these valuable materials through efficient recycling.”

Metso’s hydrometallurgical black mass recycling process has been designed to treat mechanically separated and shredded batteries for recovering battery raw materials including nickel, cobalt, lithium, manganese and copper.

“With Metso’s technology, the critical metals can be sustainably extracted from black mass and reused in new battery production or in other applications," Simola says. "Recycling of black mass from batteries with Metso’s process can reduce up to 60 percent of embedded carbon compared to use of virgin materials.”

The process is based on Metso’s VSF X Solvent extraction technology and complemented with OKTOP reactors, Larox PF filters, Dual Media (DM) and LSF filters and thickeners and scrubbers. The process flowsheet can be tailored according to feed materials and desired end products with a possible phased approach for adding more equipment for the recovery of less valuable materials, Metso says.

“With the launch of the battery black mass recycling process, our offering for the battery minerals value chain covers 90 percent of the end-to-end production process,” says Mikko Rantaharju, vice president of hydrometallurgy at Metso.

“We can provide sustainable technology and equipment for the entire lithium, nickel and cobalt production chain from the mine to battery materials and black mass recycling with project scopes ranging from equipment packages to plant deliveries,” he continues. “We can also support our customers in the design of the process with our comprehensive testing and research capabilities.”

Latest from Recycling Today

- BMW Group, Encory launch 'direct recycling’ of batteries

- Loom Carbon, RTI International partner to scale textile recycling technology

- Goodwill Industries of West Michigan, American Glass Mosaics partner to divert glass from landfill

- CARI forms federal advocacy partnership

- Monthly packaging papers shipments down in November

- STEEL Act aims to enhance trade enforcement to prevent dumping of steel in the US

- San Francisco schools introduce compostable lunch trays

- Aduro graduates from Shell GameChanger program