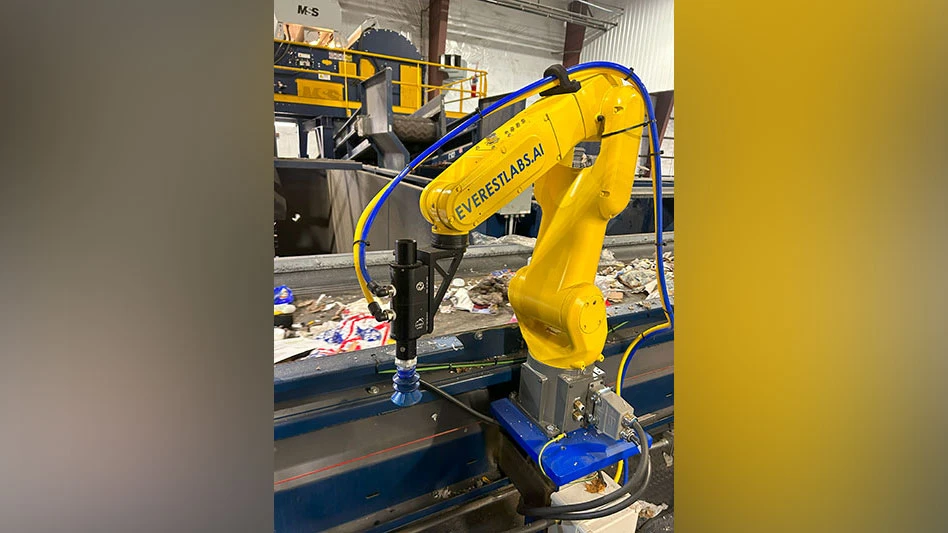

Image courtesy of BAM for EverestLabs

EverestLabs, the Fremont, California-based developer of RecycleOS, an artificial intelligence- (AI-) enabled operating system for material recovery facilities (MRFs) and recyclers, has partnered with Illinois-based LRS to install a RecycleOS material sorting robot at The Exchange, its newest material recovery facility (MRF).

Last September, LRS hosted the grand opening of The Exchange MRF, which features a sorting system supplied by San Diego-based CP Group, including six optical sorters supplied by CP Group company MSS Inc., and installed an EverestLabs RecycleOS Robotics cell earlier this year.

The Exchange accepts up to 1,200 tons per day of single-stream recyclables and processes 25 tons per hour, with the ability to divert 224 million pounds of recyclables annually.

“At LRS, we're all about pushing the boundaries in recycling, and partnering with EverestLabs to install this innovative technology amplifies our commitment to sustainable recycling solutions,” says John Sliwicki, area vice president at LRS. “By integrating EverestLabs' RecycleOS robot into our Chicagoland materials recovery facility, we've further enhanced our ability to rescue recyclables from ending up in landfills and advanced our mission of investing in infrastructure improvements that lessen our environmental impact.”

Through a lease with the Can Manufacturers Institute (CMI) members Ardagh Metal Packaging and Crown Holdings, RecycleOS was installed on the MRF’s residual line to capture used beverage cans (UBCs) that were missed earlier in the sorting process. RecycleOS assists LRS in maintaining quality control for more than 350,000 pounds of recycled aluminum each month at The Exchange, which equates to approximately 12 million aluminum beverage cans, according to a news release from EverestLabs.

The lease program is the latest in a several-year CMI effort to demonstrate the potential additional revenue MRFs can realize by capturing missorted UBCs. This effort included a collaboration between Washington-based CMI, EverestLabs and California-based Caglia Environmental to install a RecycleOS that has captured more than 1,500 additional UBCs per day at Caglia’s Cedar Avenue Recycling and Transfer Station (CARTS) MRF in Fresno, California.

“With both robot lease agreements that include a revenue share, CMI is able to leverage that UBCs are consistently one of the most valuable recyclable commodities,” says Scott Breen, senior vice president of sustainability at CMI. “CMI is receiving a portion of all revenue generated from the cans collected by the robot and then using those funds for even more can-capture equipment in MRFs.”

Breen says CMI selected LRS for funding because the company is a well-regarded MRF operator, and The Exchange installation offered the ability to capture a high volume of UBCs.

“CMI is financing can capture equipment, including this lease of a robot at The Exchange, to make progress toward its ambitious U.S. aluminum beverage can recycling targets, first of which is increasing the recycling rate to 70 percent by 2030,” he adds.

“One of the four actions to make progress toward these targets is ‘proper sortation at recycling centers,’ which has resulted in funding both grants and leases of can-capture equipment. With grants, CMI has announced six so far through a partnership with The Recycling Partnership, with equipment that will annually capture 115.5 million used beverage cans. With leases, CMI has funded two of them, both through EverestLabs.”

Regarding EverestLabs’ technology, he says, “RecycleOS guarantees robot uptime and performance can fit in a lot of different places within a MRF and provides helpful reports on how many cans it is capturing each day. Beyond the equipment, EverestLabs has a team we enjoy working with and, also, the relationships with MRFs needed to execute the can capture lease program.”

“RecycleOS fit the criteria for what was possible for installation at The Exchange in terms of size and capabilities, and EverestLabs has a track record of success in providing sustainable solutions at material recovery facilities like The Exchange,” Sliwicki says. “Additionally, the RecycleOS technology is able to remove cans from the last-chance line on pace with the more than 25 tons of recyclables per hour being processed at The Exchange, keeping our facility operating at maximum efficiency.”

He adds that while LRS doesn’t have an estimate on its missed UBCs at The Exchange, he says misses can be attributed to factors that include improperly disposed of recyclables, such as people crushing their cans or placing them in bags or containers, which makes them more difficult to detect and sort.

Capturing missorted cans at MRFs is one way to increase the U.S. aluminum beverage can recycling rate. CMI's 2020 research, "Aluminum Beverage Can: Driver of the U.S. Recycling System," found that up to 25 percent of all UBCs entering MRFs could be missorted and not recovered. Alongside its statistics showing a little less than half of aluminum beverage cans are recycled by U.S. consumers, it is evident that the aluminum recycling ecosystem needs improvement and UBCs are not being captured and used to their fullest potential in the circular economy, CMI says, noting this is why it has proper sorting at recycling centers as one of the four pillars of action to reach its U.S. aluminum beverage can recycling rate targets.

"The Exchange in Chicago is our second project with CMI, and we have been behind their mission to significantly increase the amount of UBCs recycled,” says Jagadeesh Ambati, founder and CEO of EverestLabs. “Our highly accurate, easily deployed vision systems and robots make it possible to retrofit existing sorting and last chance lines at a cost of ownership that makes perfect sense for both MRFs and aluminum packaging companies."

Latest from Recycling Today

- Radius to be acquired by Toyota subsidiary

- Algoma EAF to start in April

- Erema sees strong demand for high-volume PET systems

- Eastman Tritan product used in cosmetics packaging

- Canada initiates WTO dispute complaint regarding US steel, aluminum duties

- Indianapolis awards solid waste contract, updates recycling drop-off program

- Novelis produces first aluminum coil made fully from recycled end-of-life automotive scrap

- GPR’s hubbIT platform recognized in Georgia State University’s Marketing Awards for Excellence in Innovation