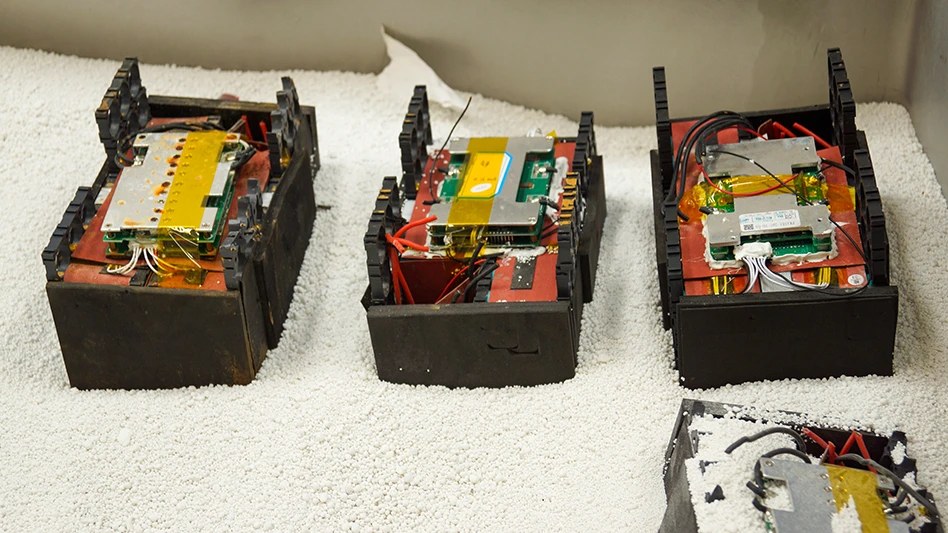

Photo courtesy of EMR Ltd.

Mirroring the growth of automotive lead-acid battery recycling in the 20th century, lithium-ion battery collection and processing is poised to grow in the next several decades.

Processing end-of-life lithium-ion batteries, whether collected from electric vehicles, smartphones or other battery-powered devices, most often includes the production of black mass. That shredded material contains a mixture of recyclable metals, with lithium, nickel, cobalt and manganese being the most common.

Shredded black mass, much like the mixed metals derived from auto shredding processes, is not produced with identical chemistry. As with numerous metal recycling applications that preceded it, buyers and sellers of black mass will benefit from knowing exactly what they are trading.

Germany-based Spectro Analytical Instruments is one of several established metals analyzing equipment providers.

This summer, Spectro published a report describing how the Spectro Arcos MultiView ICP-OES with dual side-on plasma observation (DSOI) mode can enhance sensitivity and accuracy in determining the composition of lithium, manganese, cobalt and nickel in a black mass sample.

Olaf Schulz, ICP-OES product manager for Spectro, tells Recycling Today the sample used in this application need not be sizable.

“Depending on the selected sample preparation method, between 0.1 grams and 1 gram of material is needed,” Schulz says, noting that analyzing the easily obtained sample, however, can yield information and benefits throughout the battery recycling and manufacturing supply chain.

“Within the complete recycling supply chain, elemental analysis is most helpful,” he says. He says facilities performing obsolete battery processing “up to the production of the black mass will require elemental analytical capabilities and knowledge about the elemental composition of the black mass since it determines the price for which it can be sold.

“Refiners will require the composition since it determines the refining process to be used.”

The need for detailed analysis also extends to producers of the precursor materials (pCAM) and the manufacture of new batteries, Schulz says.

“In the later stages of the recycling process the determination of major, minor and trace elements is important since they affect the performance of the final product," he continues.

Spectro's Arcos system features complementary metal oxide semiconductor (CMOS) detectors and a high resolution Paschen-Runge spectrometer mount designed to provide high sensitivity and minimal interference for accurate measurements.

The DSOI mode offers up to twice the sensitivity of traditional single radial plasma observation, while maintaining the benefits of the radial method, making it efficient for analyzing both major and trace elements in battery black mass, according to Spectro.

In its report, which can be downloaded from the Spectro website, the company compares two sample preparation methods—peroxide fusion and aqua regia extraction.

“Both methods showed excellent recoveries for major elements, with aqua regia extraction recommended for its efficiency and cost-effectiveness,” Spectro says.

“The accurate analysis of black mass is essential for the lithium-ion battery recycling industry. This new method supports better resource management by ensuring the recovery of critical elements, aligning with the sustainability goals of the electromobility and energy storage sectors.”

Latest from Recycling Today

- BMW Group, Encory launch 'direct recycling’ of batteries

- Loom Carbon, RTI International partner to scale textile recycling technology

- Goodwill Industries of West Michigan, American Glass Mosaics partner to divert glass from landfill

- CARI forms federal advocacy partnership

- Monthly packaging papers shipments down in November

- STEEL Act aims to enhance trade enforcement to prevent dumping of steel in the US

- San Francisco schools introduce compostable lunch trays

- Aduro graduates from Shell GameChanger program