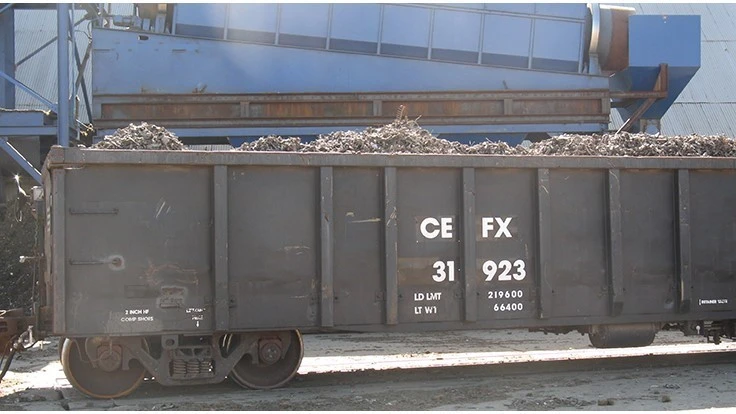

Members of the Institute of Scrap Recycling Industries (ISRI), Washington, testified before a Surface Transportation Board (STB) hearing that rail is a critical mode for transporting ferrous and nonferrous scrap metal, particularly for distances greater than 200 miles. Since many recycling facilities are served by only one major freight railroad, there are few modes of transportation. According to a news release from ISRI, this means scrap metal and other recycling companies often face poor rail service and skyrocketing transportation fees.

ISRI is calling on the STB to address unreasonable railroad practices related to rail car supply and storage fees.

“It’s time for the STB to evaluate the commercial fairness of railroad demurrage tariffs and practices, which in many cases are the result of delays across the broader rail network,” says ISRI President Robin Wiener.

Since major Class 1 freight railroads implemented “precision rail scheduling” at the beginning of 2019, scrap metal recycling companies have seen astronomical increases in shipping costs, ISRI reports in a news release. Unreasonable rail practices under this new system also include:

• reductions in available time for rail car loading, unloading and storage;

• service inconsistencies that precipitate demurrage and storage charges and impact facility operations (e.g., bunched cars or missed switches);

• the introduction of “not prepared for service” charges; and

• congestion charges.

According to an ISRI news release, the association found additional examples of unfair rail practices experienced by its members. One member reported an increase in demurrage and storage charges of 669 percent in the first two months of 2019 compared with the 2018 average. Another member paid 1,000 percent more in demurrage and storage charges per month in 2019 compared with 2017. To mitigate the expense, scrap facilities must employ a second crew or require employees to work overtime, driving up operating costs despite having no control over bunched deliveries.

Additionally, one ISRI member explained that his or her facility can only accommodate an 18-car switch, but the railroad will pool cars at various stations along the route and deliver 30 to 40 cars regardless of how they were ordered.

ISRI reports that it is asking the STB to apply the following principles in its evaluation of reasonableness of railroad demurrage practices:

• demurrage practices must serve their underlying purpose of incentivizing an efficient rail network and must not be designed to generate additional revenue for the railroads;

• railroad customers should not be penalized for railroad service failures; and

• railroad customers should be given sufficient notice to allow for adjustment of their operations.

ISRI also supports the STB’s collection and analysis of rail data on demurrage and accessorial charges in order to help ensure these fees properly and fairly incentivize rail network efficiencies, rather than simply drive profits. ISRI’s entire testimony can be viewed on the STB website. Testimonies of two ISRI members testifying in person are also available: Ben Abrams, president and CEO of Pennsylvania-based Consolidated Scrap Resources Inc. and Bobby Triesch, vice president and regional general manager of Orange, California-based SA Recycling.

Latest from Recycling Today

- BlueScope, BHP & Rio Tinto select site for electric smelting furnace pilot plant

- Magnomer joins Canada Plastics Pact

- Out of touch with reality

- Electra names new CFO

- WM of Pennsylvania awarded RNG vehicle funding

- Nucor receives West Virginia funding assist

- Ferrous market ends 2024 in familiar rut

- Aqua Metals secures $1.5M loan, reports operational strides