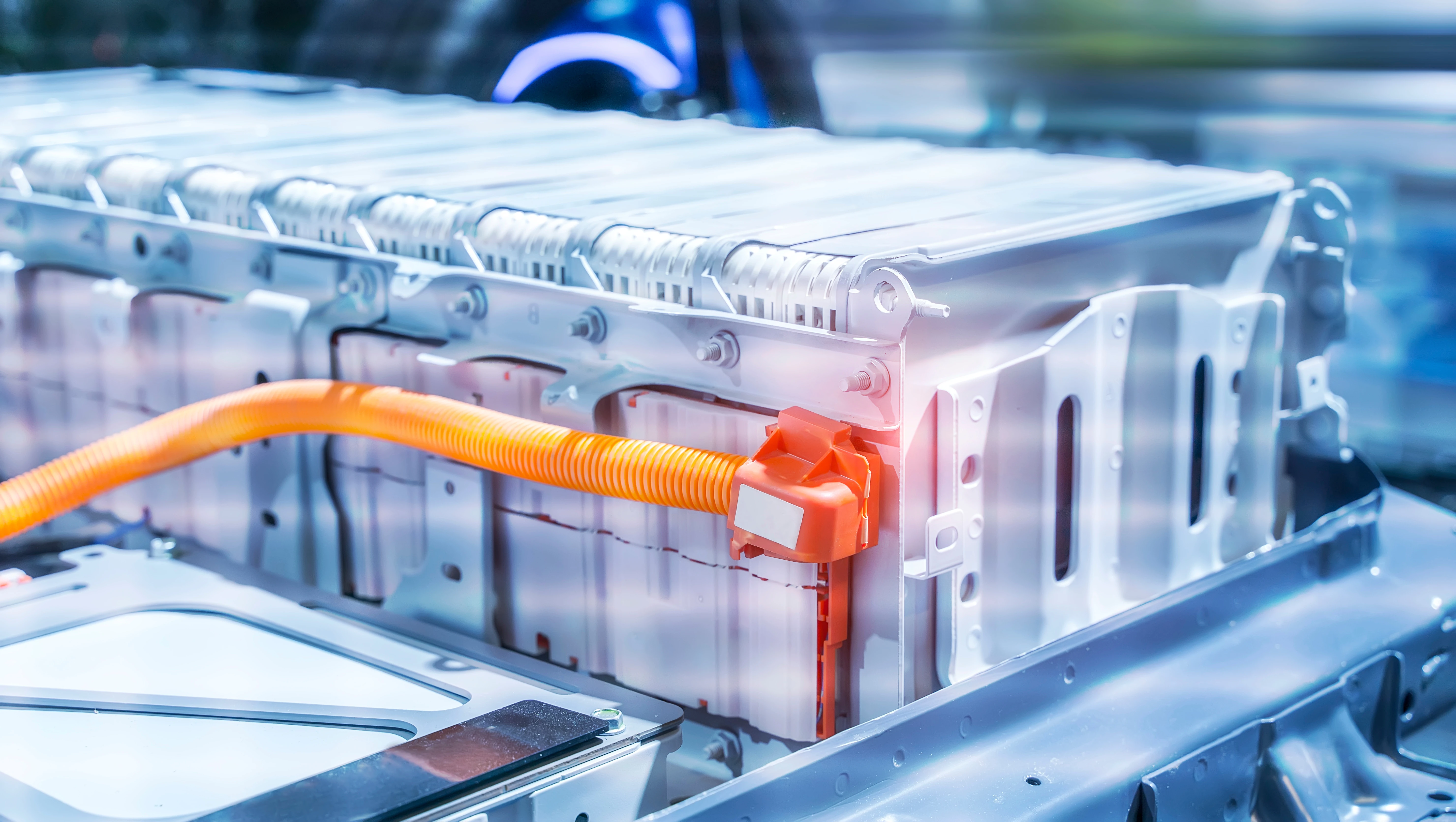

xiaoliangge | stock.adobe.com

According to Daniel Majano, program manager at the Arlington, Virginia-based Electrical Safety Foundation (ESF), contact with or exposure to electricity continues to be one of the leading causes of workplace injuries and fatalities in the United States, and with electrification on the rise, emerging areas of electrical safety include energy storage systems, electric vehicles and lithium-ion batteries.

Majano presented during a session called Empowering Excellence: Electric Vehicle Battery Removal Mastery and Safety Protocol Training Overview at the 2024 Institute of Scrap Recycling Industries (ISRI, which has been renamed to the Recycled Materials Association, or ReMA) Convention and Exhibition in Las Vegas in mid-April. He cited data from the U.S. Consumer Product Safety Commission (CPSC) that reveal more than 25,000 incident reports related to lithium-ion batteries have been made and more than 5,000 lithium-ion battery-related fires occur per year at recycling facilities.

The session also featured other battery and electrical safety experts, including Niel Speetjens of the Automotive Certified Training Academy, Chelsey Schneider of the Energy Security Agency (ESA) and George Steele, transportation safety director at the Reserve Management Group.

By the end of this year, the U.S. Energy Information Administration estimates battery storage is expected to reach about 23 percent of all planned utility-scale electric-generating capacity, second only to solar applications at 58 percent.

“We know these batteries are in all sorts of everyday electronic devices like toothbrushes, cellphones, laptops, cars, micromobility and so on,” he said. “These batteries, when used to charge directly to the source, they’re safe. But problems happen when they’re not handled correctly or when they are not recycled properly.”

Majano presented ESF data that show electrical fatalities in the workplace have remained essentially flat from 2011 to 2022 and said the challenge has been educating workers on minimizing risk around electricity.

The ESA has spent the last 10 years studying those exact challenges—developing a test site to determine the impacts of electricity and, specifically, batteries, and how to educate workers as well as first responders. The site tests what happens to batteries when they are punctured or overcharged, for example, and Schneider said for the past four years, the ESA has used that research to “get everybody on the same page so we’re all under the same safety umbrella.”

Schneider added that the ESA was approached by ReMA as batteries became more prolific in the recycling stream, particularly recyclers operating auto shredders, and asked the ESA to help provide more comprehensive safety training.

“We can interact with these [batteries], we just have to learn how to safely do it,” she said.

What the current guidance suggests

There currently is no legislation on how to handle electric vehicles (EVs) and their batteries, but Schneider said the ESA follows federal standards recognized by the National Transportation Safety Board, Society of Automotive Engineers, National Fire Protection Agency and National Highway Traffic Safety Administration.

The guidance includes steps to take when identifying vehicles, conducting risk assessments, towing and storing vehicles as well as hazard management tips.

“We teach our experience and what we’ve learned on the job, but we also try to use these standards that are out there,” Schneider said of her own experience as a first responder.

The first step—identifying vehicles—involves several different identification procedures.

Schneider said the first step a recycler should take is a sense assessment, using sight, smell and sound to determine if any aspect of the vehicle or its battery is problematic.

An engineering assessment is next, using energy management, thermal cameras or four-gas meters, for example, to assess the safety of the vehicle before finally running a diagnostic assessment that includes interpreting any codes that come up when testing the vehicle.

Once a vehicle has been properly identified, Schneider said tagging the vehicle is the simplest way to communicate its status, using red, yellow and green tags with specific instructions to help workers easily determine the best way to properly handle or store the vehicle.

When handling a vehicle, Schneider said to never lift EVs from underneath, as that pressure on its battery pack can cause an explosion or other battery-related incident.

Finally, she described several ways to address hazard management, including concrete dividers, which can be used to segregate high-risk EVs, and vehicle fire blankets, which can be used to contain thermal runaways.

“These vehicles, these batteries—are they dangerous? Yes,” Schneider said. “But can we handle them? Absolutely, we just don't have the right tools. We need to invest so people are getting the right training, invest in some different products … to be able to handle these and handle them safely.”

Latest from Recycling Today

- Orion ramping up Rocky Mountain Steel rail line

- Proposed bill would provide ‘regulatory clarity’ for chemical recycling

- Alberta Ag-Plastic pilot program continues, expands with renewed funding

- ReMA urges open intra-North American scrap trade

- Axium awarded by regional organization

- Update: China to introduce steel export quotas

- Thyssenkrupp idles capacity in Europe

- Phoenix Technologies closes Ohio rPET facility