Ineos Styrolution, which is headquartered in Frankfurt, Germany, has announced that it is collaborating with Polystyvert, which is based in Montreal, to convert postconsumer polystyrene (PS) into high-quality PS raw material.

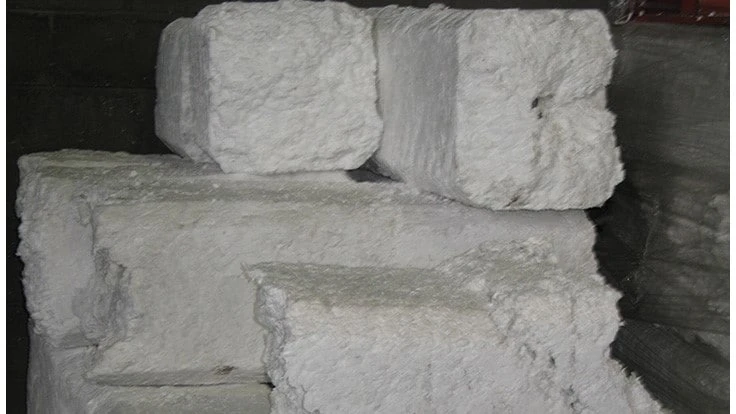

According to a news release from Ineos Styrolution, Polystyvert uses a patented dissolution technology to process PS scrap into high-quality recycled PS. The dissolution method of advanced recycling takes plastic scrap in its solid form and dissolves it using a solvent. Once dissolved, the process can mechanically and chemically separate contaminants and additives, before finally separating the original polymer from the solvent. Ineos Styrolution says the end product is a cleaned polymer that may be used as new raw material resin again.

According to Ineos, Polystyvert’s purification technology offers the ability to treat a variety of feedstocks, from industrial scrap to postconsumer scrap. The technology can eliminate a wide range of hard-to-remove contaminants, such as pigments and brominated flame-retardants. Recycled PS pellets can then be used to manufacture various categories of polystyrene products, including food-grade applications.

“The purification capacity of Polystyvert’s technology is unique,” says Ricardo Cuetos, vice president of Ineos Styrolution Americas, Standard Products. “The high quality of the final recycled polystyrene resin is essential to achieving a truly circular economy in key markets like food-service packaging.”

Solenne Brouard, CEO of Polystyvert, states, “Dissolution is an efficient, low-energy technology which offers a cost-effective solution to recycle polystyrene in a closed loop.” Using this method, she says, “recycled polystyrene is produced at a competitive price. Thus, opening up the full potential for a circular economy.”

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Latest from Recycling Today

- Sofidel agrees to purchase Royal Paper assets

- US Plastics Pact report charts expansion path for recycled content in packaging

- USTR announces phased measures designed to address China’s shipbuilding dominance

- APR, RecyClass release partnership progress report

- Clearpoint Recycling, Enviroo sign PET supply contract

- Invista expanding ISCC Plus certification program

- Redwood partnership targets recycling of medium-format batteries

- Enfinite forms Hazardous & Specialty Waste Management Council