Image courtesy of Indorama Ventures Public Co. Ltd.

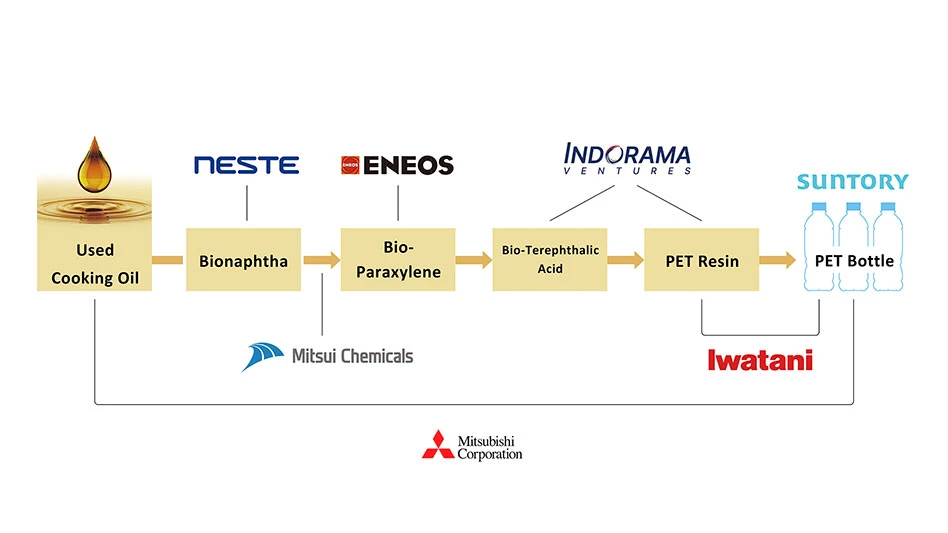

Indorama Ventures Public Co. Ltd., headquartered in Thailand, has collaborated with Eneos Corp., Mitsubishi Corp., Iwatani and Neste to launch what it says is the world’s first commercially available bio-polyethylene terephthalate (PET) bottle made using ISCC+ certified bio-paraxylene derived from used cooking oil and offering reduced CO2 emissions.

A spokesperson for Indorama says the resulting PET bottles can be conventionally recycled without adversely affecting the material stream.

Beginning in November, the Suntory Group introduced these bio-PET bottles for selected products in Japan. The collaboration will launch approximately 45 million PET bottles for beverages made with this material, with further introduction for Suntory products to be considered in the future.

The initiative, which combined the expertise and resources of industry leaders across the value chain, illustrates the power of collaboration in addressing global sustainability challenges, Indorama says.

“This exciting collaboration reflects the shared vision and responsibility of all partners involved to contribute to a more sustainable future,” says Yash Lohia, executive president of petchem special projects and chairman of the ESG Council at Indorama Ventures. “We are proud to work alongside industry leaders in this pioneering effort, which not only brings new possibilities to the packaging industry but also reinforces the importance of collaboration in driving meaningful change. And we are excited to see the fruits of the collaboration on the shelves soon as high-quality Suntory products."

Within the global supply chain through cross-industry collaboration, Indorama says it took bio-paraxylene to create terephthalic acid, then reacted it with monoethylene glycol to produce PET resin.

Mitsubishi managed the entire supply chain, while Finnish company Neste produced bio-naphtha from used cooking oil in an ISCC+ certified plant. Mitsui Chemicals of Japan then produced the intermediate bio-paraxylene using bio-naphtha in ISCC+ certified plant, while Japanese company Eneos produced bio-paraxylene from intermediate material in ISCC+ certified plant using mass balance approach. Indorama then produced PET resin by reacting MEG with PTA (TPA) produced with bio-paraxylene in ISSC+ certified plants, with Iwatani of Japan managing operations from production to delivery of PET resin and Suntory forming the PET resin into bottles for its products.

This launch represents a major step forward in reducing the environmental footprint of PET production. The mass balance approach applied throughout the production process ensures the bio-based materials are transparently and effectively integrated into the PET bottles, the company says.

The production of bio-PET resin aligns with Indorama’s long-term sustainability strategy and strengthens its commitment to providing environmentally responsible solutions to its customers.

Latest from Recycling Today

- BMW Group, Encory launch 'direct recycling’ of batteries

- Loom Carbon, RTI International partner to scale textile recycling technology

- Goodwill Industries of West Michigan, American Glass Mosaics partner to divert glass from landfill

- CARI forms federal advocacy partnership

- Monthly packaging papers shipments down in November

- STEEL Act aims to enhance trade enforcement to prevent dumping of steel in the US

- San Francisco schools introduce compostable lunch trays

- Aduro graduates from Shell GameChanger program