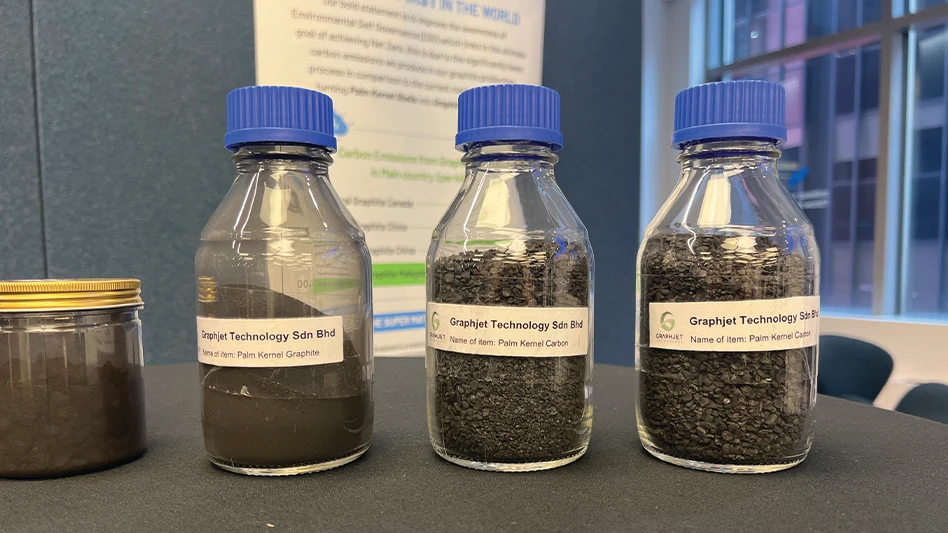

Photo courtesy of Graphjet Technology

Graphjet Technology, a developer of patented technologies to produce graphite and graphene directly from palm kernel material, plans to build a commercial artificial graphite production facility in Nevada.

The company is evaluating a specific location for the facility that will sit on approximately 21 acres and create about 500 jobs. Graphjet expects to commission and begin production at the new facility in 2026.

Graphjet, headquartered in Kuala Lumpur, Malaysia, expects the plant to be capable of recycling up to 30,000 tons of palm kernel material equivalent to produce up to 10,000 metric tons of battery-grade artificial graphite per year, noting that this level of production is expected to be able to support the production of enough batteries to power more than 100,000 electric vehicles (EVs) per year. The palm kernel material it uses is widely abundant in Malaysia and Indonesia and typically is landfilled, turned into fertilizer or burned to generate electricity for power plants.

For now, Graphjet co-founder and CEO Aiden Lee tells Recycling Today the plan is to focus on sourcing this material from Malaysia for its feedstock given its cost-effectiveness and ability to reduce the company’s carbon footprint, though it has experimented with other types of feedstock.

“We have also used sawdust, coconut shells, rice husks, plastic waste and rubbish in our R&D [research and development], and our proprietary technology demonstrates the best results and yields come from palm kernel shells,” Lee says.

In addition to producing graphite, Graphjet says its first commercial plant in Malaysia is on track to be commissioned in the second quarter of this year and will process palm kernel shells into hard carbon, which will be shipped to the new Nevada plant and allow it to produce graphite more quickly.

To make its artificial graphite, Graphjet takes palm kernel shells collected from palm oil mills and performs a drying and crushing process, then uses its proprietary manufacturing process to produce hard carbon. The hard carbon is then converted to palm kernel-based graphite. Following the production of graphite, Lee says the company conducts high-temperature graphitization and graphene preparation to produce graphene.

“As the only pure-play direct agriculture waste-to-graphite technology developer, Graphjet is well-positioned to become the leading source of graphite for the U.S., and we are excited to have Nevada serve as our launching pad into this market,” Lee says. “We are laser-focused on getting our commercial production online as quickly as possible and are in discussions with several players to secure offtake agreements for our planned Nevada facility. We look forward to investing into the region and creating many local green energy jobs as we build a first-of-its-kind, next-generation graphite production facility in the U.S.”

The company says Nevada is a strategic location as it is located in proximity to numerous battery manufacturers and automotive original equipment manufacturers (OEMs), which Graphjet says will require a significant amount of graphite for future EV battery production.

In addition to creating approximately 500 jobs, Graphjet says it expects to invest between $150 million and $200 million into the facility and currently is evaluating financing and strategic options to fund the plant.

“As leading automotive OEMs and battery manufacturers seek cost-effective and more environmentally friendly sourced production, Graphjet is able to provide a sustainable and cost-effective solution that can support their graphite needs and address the accelerating demand for this strategic material.”

As an example, Lee says Graphjet’s technology produces 2.95 CO2 emissions per kilogram of graphite, compared with 17 CO2 emissions per kilogram with synthetic graphite in China and 9.2 CO2 emissions per kilogram with natural graphite in Canada.

Latest from Recycling Today

- Cyclic Materials to build rare earth recycling facility in Mesa, Arizona

- Ecobat’s Seculene product earns recognition for flame-retardant properties

- IWS' newest MRF is part of its broader strategy to modernize waste management infrastructure

- PCA reports profitable Q1

- British Steel mill subject of UK government intervention

- NRC seeks speakers for October event

- LME identifies Hong Kong warehouses

- Greenville, Mississippi, launches aluminum can recycling program