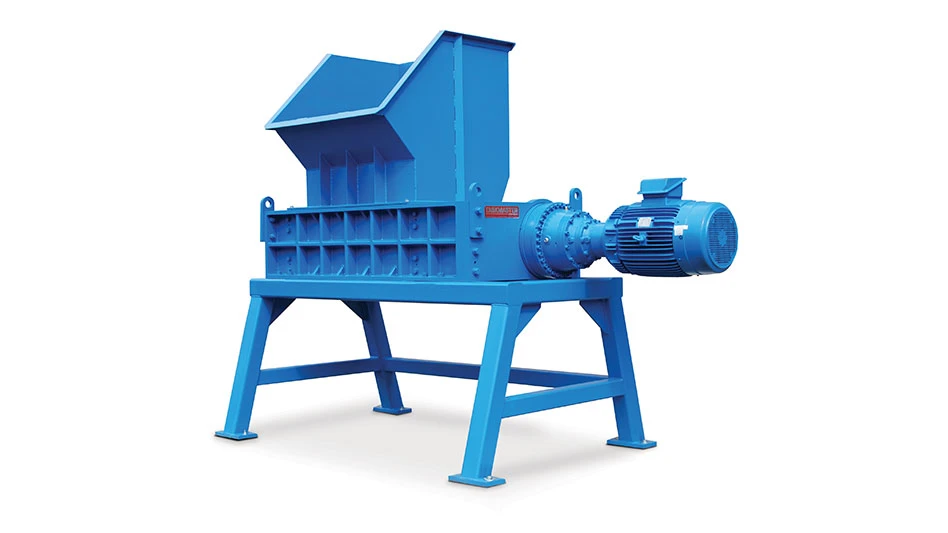

Photo courtesy of Franklin Miller

Franklin Miller, headquartered in Livingston, New Jersey, has released the Taskmaster TM3000, a line of heavy-duty industrial shredder engineered with a low-speed, high-torque configuration.

The shredders in the TM3000 line, the TM3042 and TM3054, can handle an array of shredding applications with large throat openings and extra heavy-duty construction. Its design ensures minimal noise, sparking, dust and heat rise, according to the manufacturer.

The TM3000 line's construction features 5.5-inch heat-treated alloy steel hexagonal shafting, 2-inch cam cutters and heavy steel plate and channel body construction complemented by a planetary gear drive system. Shredders in the TM3000 line, with or without stand and hopper, can be installed directly in an enclosed system as the housing extends beyond the cutters for enhanced safety.

Capable of ripping, tearing and shredding tough solids, the TM3000 reduces the volume of material for further processing or disposal. Its heavy-duty 5-1/2-inch (140-millimeter) hardened alloy hexagonal shafts and high-strength bearings ensure a rigid and dependable drive train, according to Franklin Miller, while the spline input guarantees efficient power transmission from reducer to shredder.

Latest from Recycling Today

- Advancing corrosion protection for recycled aluminum

- Plastics treaty talks to resume in August

- Evertis investing $100M in new US production facility

- Altilium appoints managing director

- Reclaim project launches portable, AI-powered robotic recycling plant

- ND Paper to restart paper machine at Biron mill in Wisconsin

- Acerinox reports profitable 2024

- DS Smith finds sustainability remains consumer priority