Photo courtesy of Electra Battery Materials Corp.

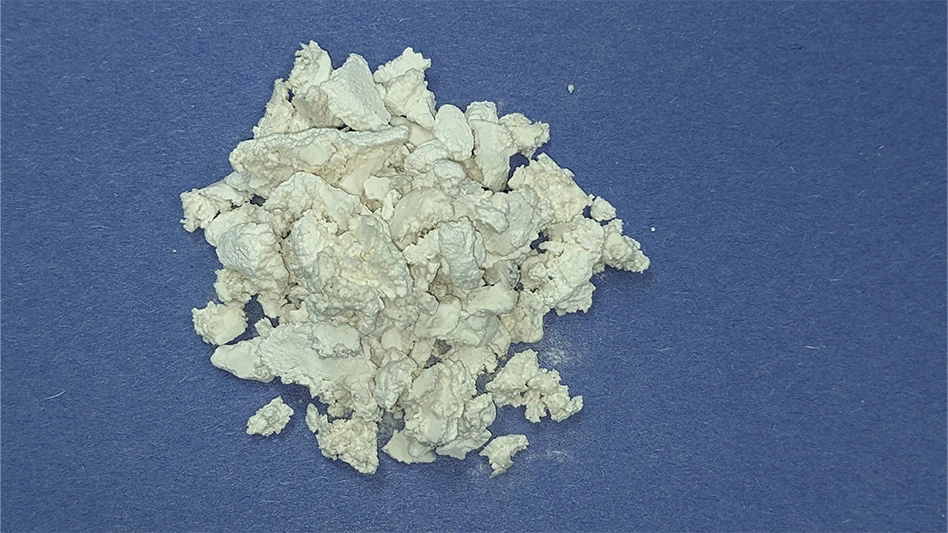

Electra Battery Materials Corp., Toronto, says it has successfully recovered lithium, a critical mineral needed for the electric vehicle (EV) supply chain, in its black mass recycling trial taking place at its refinery north of Toronto.

The company says the recovery and subsequent production of a technical-grade lithium carbonate product in a plant-scale setting validates its hydrometallurgical process and efforts to date in commissioning its larger refinery complex.

RELATED: Electra achieves plant-scale recycling of black mass

“Recovering lithium from black mass represents a potential game-changer for Electra and the North American EV supply chain,” Electra CEO Trent Mell says. “Recycling lithium from expired batteries through hydrometallurgy lowers the carbon footprint of manufacturing electric vehicles and represents an important source of future supply for a commodity whose demand is expected to grow significantly in the coming years. From Electra’s perspective, it considerably strengthens the economics of our battery recycling strategy by providing another high-value product we can sell.”

Mell continues, “Successfully demonstrating our lithium recovery process in a plant-scale environment supports our plans to commercialize our process with our industry partners and is a testament to efforts of Electra’s technical team.”

Electra Vice President of Project Development Mark Trevisiol adds that the company’s refinery team and its consulting engineering partners achieved the milestone in less than two years, going from bench-scale laboratory testing to plant-scale production.

The company says established North American battery recyclers have focused on collecting and shredding batteries, with the resulting black mass material primarily being treated by a pyrometallurgical smelting process that has a higher carbon footprint and lower metal recoveries than hydrometallurgical processes.

It adds that recycling black mass will increasingly become a key feature of the EV battery supply chain given the strong demand for critical minerals and the looming supply deficit of metals such as nickel and cobalt. Electra cites data from global consultancy McKinsey & Company that says available battery material for recycling is expected to grow by 20 percent per year through 2040.

Electra launched its black mass demonstration plant at the end of December 2022 and has processed material in a batch mode, successfully extracting lithium, nickel, cobalt, manganese, copper and graphite. The company says it has decided to extend its black mass processing and recovery activities through June of this year, beyond its initial target of 75 tons, as a result of preliminary results achieved to date, and interest expressed by potential commercial partners.

The total amount of material to be processed and recovered through June will be determined in the coming weeks, the company says, adding that it has identified multiple sources of supply and is in discussions on terms and conditions with vendors.

Electra says all of its recovered material will be sold to third-party companies for additional processing and reuse in a number of applications.

Latest from Recycling Today

- Haber raises $44M to expand to North America

- Canada Plastics Pact releases 2023-24 Impact Report

- Reconomy brands receive platinum ratings from EcoVadis

- Sortera Technologies ‘owning and operating’ aluminum sorting solutions

- IDTechEx sees electric-powered construction equipment growth

- Global steel output recedes in November

- Fitch Ratings sees reasons for steel optimism in 2025

- P+PB adds new board members