Sergii | stock.adobe.com

Electra Battery Materials Corp. has received CA$5 million ($3.6 million) in funding from Natural Resources Canada to support the development of its proprietary battery materials recycling technology.

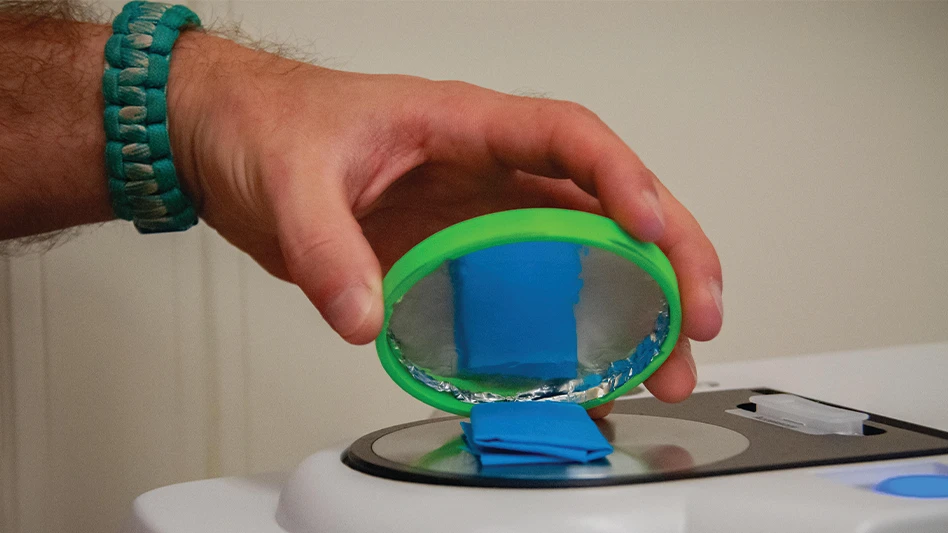

In 2023, the Toronto-based company says it successfully operated a battery materials recycling demonstration plant in a batch process at its refinery complex, processing more than 40 tons of black mass and producing high-quality nickel, cobalt and lithium products.

Building on the performance of the demonstration plant, Electra is accelerating the next phase of its recycling project to demonstrate on a continuous basis that its hydrometallurgical black mass process is scalable, profitable and can be implemented at other locations. The Canadian government, through Natural Resources Canada’s Critical Minerals Research, Development and Demonstration program, has committed the funding for this project, which will be based at the company’s facility located in Temiskaming Shores—approximately five hours north of Toronto.

RELATED: Electra provides battery recycling update

“Today’s funding announcement is a clear signal from the government of Canada of its ongoing commitment to creating a strong, sustainable EV [electric vehicle] supply chain,” Electra CEO Trent Mell says. “While recycling critical minerals is part of our business strategy, we also remain focused on the construction of our cobalt sulfate refinery and look forward to updating the market with funding developments to restart construction.

“Our recycling project is part of the growth plan for the refinery complex and we are thankful for this investment as it allows us to speed up the development of our proprietary battery metals recycling technology. Electra’s black mass recycling expertise can contribute to the production of clean, secure and ethically sourced materials for the EV supply chain in North America.”

Mell says the recycling of battery materials will become more critical as the EV industry expands in North America, and Electra is strengthening its development timelines through partnerships with government and industry entities, such as the Three Fires Group, with which Electra is exploring the development of a battery material shredding facility in Ontario. “Our refinery is positioned to be the first of its kind for recycling, a hydrometallurgical black mass facility in North America, and could provide recycling as a service to the many gigafactories coming to Ontario.”

The funding announcement was made in Sudbury, Ontario, alongside an announcement of funding into the Mining Innovation Rehabilitation and Applied Research Corp. (MIRARCO).

“Today’s total investment of $10 million to Electra and MIRARCO will help to advance the development of dynamic and competitive critical minerals value chains in Canada and northern Ontario," says Jonathan Wilkinson, Canadian minister of energy and natural resources. "This funding will increase mineral and energy security, create good jobs and support economic opportunities—supporting our work to build a cleaner Canada and a prosperous, sustainable economy that works for everyone.”

Electra is constructing a cobalt sulfate refinery north of Toronto as part of a multiphase effort to onshore refining capabilities for cathode materials. The company says its priority is to secure the capital required to recommission and expand the refinery, and its long-term vision includes additional phases to provide recycled battery materials and battery-grade nickel to the North American and global EV battery market.

The company claims its 2023 recycling demonstration program is the first plant-scale recycling of black mass material in North America, as well as the first domestic production of nickel-cobalt mixed hydroxide precipitate product (MHP). The company’s hydrometallurgical process successfully recovered MHP, lithium carbonate, graphite and other commercial products from 40 tons of black mass.

RELATED: Electra to extend black mass processing trial

During the yearlong trial, recovery rates for all targeted metals improved, with recovery of manganese improving by more than 50 percent from results achieved in a lab setting, according to the company. The metal content in the MHP increased 5-10 percent over the course of the trial. By early 2024, the quality of the company’s lithium carbonate was approaching technical grade.

The funding from Natural Resources Canada will allow Electra to continue testing its black mass refining to optimize the process parameters and reagent consumption as well as maximize the percentage of recovery for critical metals and their quality. The company also will explore the potential of isolating cobalt from nickel contained in the MHP product to improve the overall payability of both the resultant cobalt and nickel product.

Ultimately, Electra says this program will support commercial discussions with battery cell manufacturers seeking North American-based solutions for a circular supply chain.

Latest from Recycling Today

- APR launches Recycling Leadership Awards

- Private equity firm announces majority investment in Sprout

- Author predicts spike in silver’s value

- SWANA webinar focuses on Phoenix recycling collaboration

- Domestic aluminum demand up through Q3 2024

- IntelliShift honored at IoT Breakthrough Awards

- Ace Green Recycling finalizes plans for battery recycling site in India

- Ambercycle, Benma partner to scale circular polyester