Image courtesy of the Pacific Northwest National Laboratory

The Department of Energy (DOE) Pacific Northwest National Laboratory in Richland, Washington, says it has worked with Canada-based automotive components maker Magna International on a new manufacturing process through which aluminum scrap can be collected and “transformed directly into new vehicle parts using an innovative process being developed by the automotive industry, in particular for electric vehicles [EVs].”

The patented Shear Assisted Processing and Extrusion (ShAPE) process collects factory-generated scrap trimmings from automotive and supplier plants and transforms it directly into suitable material for new vehicle parts, the DOE says. The technology now is being scaled to make lightweight aluminum parts for EVs.

The process, according to the DOE, “eliminates the need to add newly mined aluminum to the material before using it for new parts. By reducing the cost of recycling aluminum, manufacturers may be able to reduce the overall cost of aluminum components, better enabling them to replace steel.”

“We showed that aluminum parts formed with the ShAPE process meet automotive industry standards for strength and energy absorption," says Scott Whalen, lead researcher on the project. "The key is that ShAPE process breaks up metal impurities in the scrap without requiring an energy-intensive heat treatment step. This alone saves considerable time and introduces new efficiencies.”

A new report and research leading up to it are part of a four-year partnership with Magna, the DOE says.

“Sustainability is at the forefront of everything we do at Magna, from our manufacturing processes to the materials we use,” says Massimo DiCiano, manager of materials science at Magna. “The ShAPE process is a great proof point of how we’re looking to evolve and create new sustainable solutions for our customers.”

The DOE says that while the automotive industry currently recycles most of its aluminum, it also can add newly mined primary aluminum to it before reusing it to dilute impurities.

Metals manufacturers most often create aluminum billets made from melting ingredients at temperatures of more than 1,000 F, according to the department. The melt shop step dissolves clusters of impurities, such as silicon, magnesium or iron, in the raw metal and distributes them uniformly in the billet through a process known as homogenization.

By contrast, the ShAPE process “accomplishes the same homogenization step in less than a second [and] then transforms the solid aluminum into a finished product in a matter of minutes with no preheating step required.”

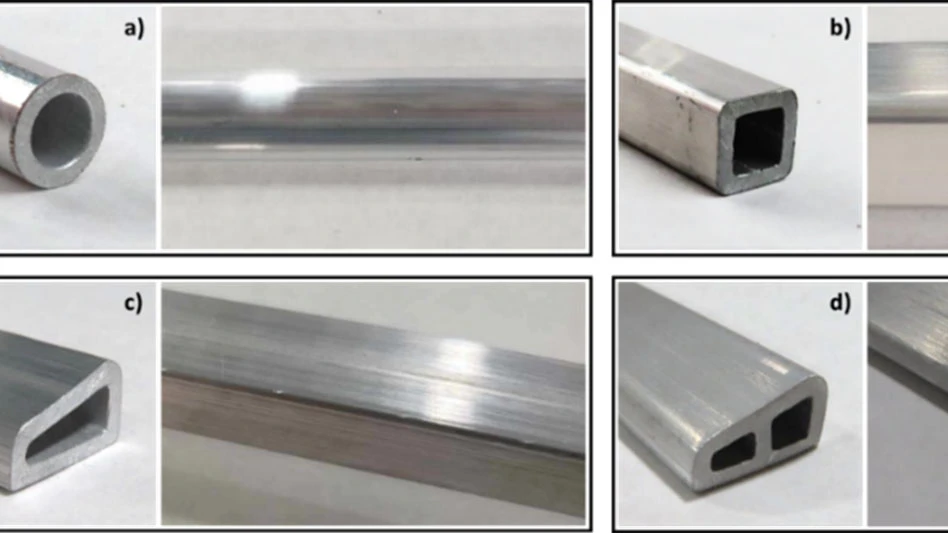

“With our partners at Magna, we have reached a critical milestone in the evolution of the ShAPE process,” Whalen says. “We have shown its versatility by creating square, trapezoidal and multicell parts that all meet quality benchmarks for strength and ductility.”

For its experiments, the research team worked with the 6063 aluminum alloy, also known as architectural aluminum. This alloy also is used for a variety of automotive components, including engine cradles, bumper assemblies, frame rails and exterior trim.

The DOE research team now is examining even higher-strength aluminum alloys typically used in battery enclosures for EVs.

“We are now working on including postconsumer [scrap] streams, which could create a whole new market for secondary aluminum scrap,” Whalen adds.

In addition to Whalen, the DOE research team included Nicole Overman, Brandon Scott Taysom, Reza-E-Rabby, Mark Bowden and Timothy Skszek. In addition to DiCiano, Magna contributors included Vanni Garbin, Michael Miranda, Thomas Richter, Cangji Shi and Jay Mellis.

Latest from Recycling Today

- Vermeer announces plan to build new facility in Des Moines metro area

- PureCycle, Toppan partner on packaging containing PCR

- LKQ to focus on simplification, productivity in uncertain demand environment

- Supreme Court strikes down IEEPA tariffs

- Redwood expands San Francisco R&D footprint

- Constellium posts record Q4 adjusted EBITDA

- QCC torches include customizable features

- Umicore finishes 2025 with increased earnings