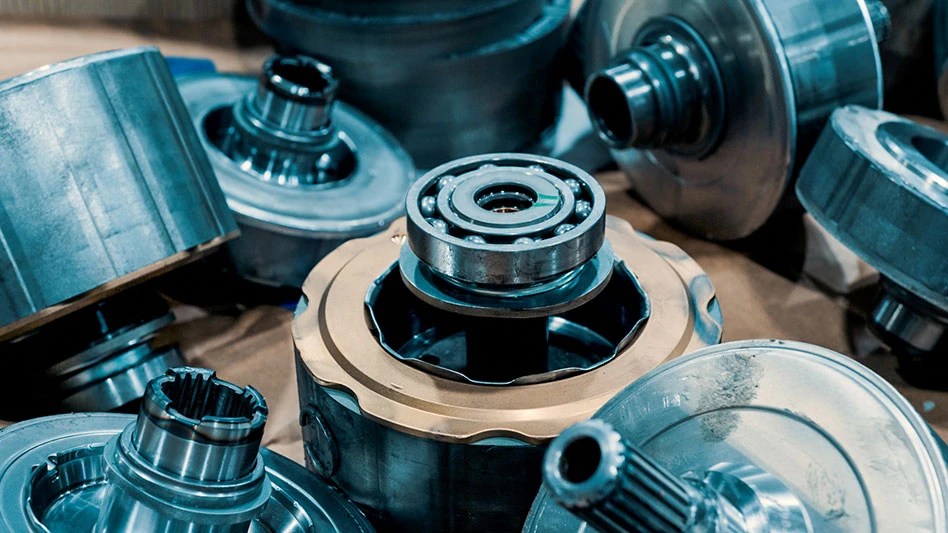

Photo courtsey of Cyclic Materials

Toronto-based Cyclic Materials, a metals recycling company targeting rare earth elements (REEs) and other critical metals, has signed a multiyear offtake agreement with Glencore. Through the agreement, Cyclic Materials will supply copper produced at its spoke operations, advancing sustainable practices in the rare earths industry and driving copper circularity while addressing growing demand for the recycled materials central to the energy transition.

This is the first agreement Cyclic Materials has signed to supply copper. The company previously signed an agreement with Solvay concerning mixed rare earths oxides (MREO). Copper and MREO represent two of Cyclic's main products that will be produced at commercial scale, according to a spokesperson for the company.

Under the terms of the agreement, Cyclic Materials will provide copper extracted from recycled electronic scrap. Glencore will further process and refine the copper at its Horne Smelter and Canadian Copper Refinery (CCR) into copper cathode that can be used in new products. Copper is one of the eight critical materials used in many technologies related to electrification and the energy transition as defined by the United States Department of Energy. This collaboration agreement aligns with both companies' commitment to reducing environmental impact and waste through promoting responsible use of all available resources.

RELATED: Critical Mineral Consistency Act passes House

“This is a significant milestone in establishing key partners to purchase our recycled materials and close the loop for all critical materials we will produce,” Cyclic Materials co-founder and CEO Ahmad Ghahreman says. “We’re eager to further partner with Glencore and expand our offtake agreements for the primary materials we will recover, prior to ramping up our operations to global commercial scale, opening new facilities in the US and in Europe to better serve our partners where they are.”

“We share Cyclic Materials’ vision to create a circular supply chain for the materials required for the energy transition,” Glencore’s Global Head of Recycling Kunal Sinha adds. “Adding Cyclic Materials as a partner broadens the scope of our recycling activities in this field as we will now receive copper materials from electric motors in addition to other metals we already recycle, such as battery materials. We see Cyclic Materials filling a critical gap in the market with their focus on rare earth recovery, a much-needed solution to further drive sustainability in critical materials.”

Glencore has signed similar offtake agreements in recent years.

In November, Toronto-based lithium-ion battery recycler Li-Cycle amended and restated its offtake agreement with Glencore to purchase 100 percent of the mixed hydroxide precipitate (MHP) produced at Li-Cycle’s Rochester Hub facility in New York based on market prices for the nickel and cobalt contained within the MHP. The companies also have agreed to extend the scope of the existing offtake agreements to cover material produced for Li-Cycle under tolling agreements with third parties.

Glencore also signed a 15-year agreement with Ace Green Recycling, headquartered in Singapore, in late 2022 to purchase up to 100 percent of the recycled lead and key end products recovered from recycled lithium-ion batteries.

Established in 2021, Cyclic Materials’ proprietary technologies can recover critical raw materials from end-of-life electric vehicle motors, wind turbines, MRI machines and data center electronic scrap. Over the past year, the company has formed strategic partnerships with companies such as Solvay, Vattenfall, Synetiq and Vacuumschmelze to recycle magnets containing REEs and establish a circular supply chain.

In 2023, Cyclic Materials commissioned a commercial demonstration facility for the first stage of its process to recover rare earth magnets from end-of-life materials using its proprietary MagCycle process. In 2024, Cyclic Materials opened a second commercial demonstration facility for the second stage of its process, in Kingston, Ontario, where MREO is produced using its proprietary hydrometallurgical technology, REEPure. The company says it is scaling its technology across North America, Europe and Asia and has oversubscribed its $53 million Series B equity round to help with its expansion.

Latest from Recycling Today

- ICM to host co-located events in Shanghai

- Astera runs into NIMBY concerns in Colorado

- ReMA opposes European efforts seeking export restrictions for recyclables

- Fresh Perspective: Raj Bagaria

- Saica announces plans for second US site

- Update: Novelis produces first aluminum coil made fully from recycled end-of-life automotive scrap

- Aimplas doubles online course offerings

- Radius to be acquired by Toyota subsidiary