NVB Stocker | stock.adobe.com

Cyclic Materials, a Toronto-based advanced metals recycling company specializing in rare earth elements and other critical metals, has signed a collaboration agreement with U.K.-based Synetiq, an integrated vehicle salvage and recycling company, for the recycling of electric motors.

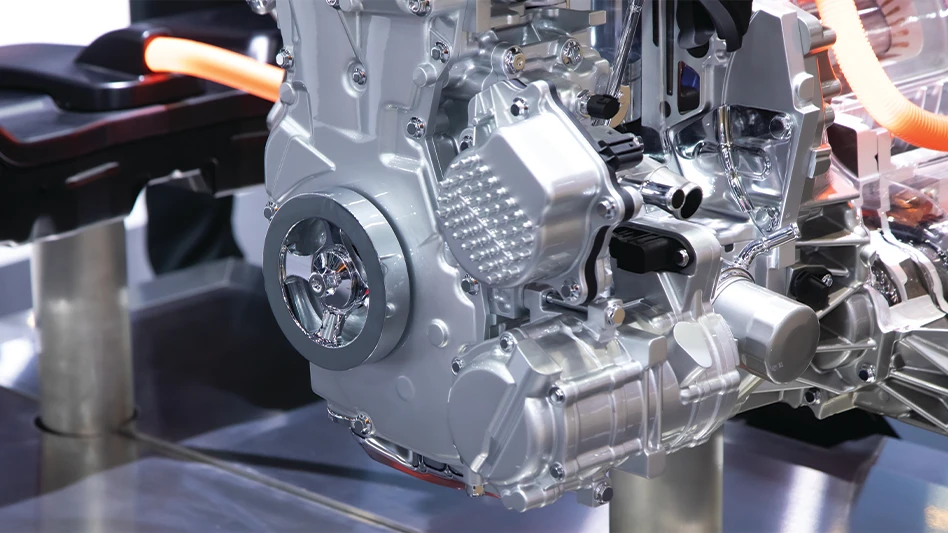

Cyclic says the motors will be supplied by Synetiq, an IAA company, and will include drive motors in hybrid and electric vehicles (EVs), as well as auxiliary motors present in all vehicles.

RELATED: Cyclic Materials receives Microsoft investment

“This relationship marks Cyclic Materials’ first overseas feedstock contract, a significant milestone as we continue to expand our business from North America across Europe in the months ahead,” says Patrick Nee, senior vice president of strategic partnerships and Cyclic co-founder. “Partnering with Synetiq was a clear decision, as both companies are committed to circular alternatives, specifically for electric motors. This agreement represents a notable step forward in our mission to advance sustainable solutions for rare earth recycling to drive the circular economy forward across the globe. Together, we are committed to accelerating industrywide change in how electric motors are recycled.”

Since 2021, Cyclic says it has focused on developing technologies capable of economically, sustainably and domestically transforming end-of-life products into valuable raw materials, adding that the recycling of rare earths delivers significant environmental benefits compared to mining processes, including a reduced carbon footprint and water usage. The company recently opened its Kingston, Ontario-based Hub100 commercial demonstration plant, which deploys its proprietary hydrometallurgical technology, REEPure, and helps fulfill increasing demand for domestic sources of mixed rare earth oxide (MREO) in North America.

Cyclic says its proprietary Mag-Cycle and REEPure technologies have the capacity to separate magnets from end-of-life products such as electric motors and convert this magnet product to mixed rare earth oxides, cobalt-nickel hydroxides and other raw materials. Feedstock from Synetiq will be received by its “spoke” facility and processed with Mag-Cycle before ultimately being sent to Cyclic’s Hub100 plant for processing using REEPure technology.

“We are excited to announce Synetiq’s new collaboration with Cyclic Materials,” Synetiq Commercial Director Michael Hill says. “At the core of our circular model, this agreement exemplifies our commitment to sustainability, innovation and responsible practices.”

Latest from Recycling Today

- ReMA opposes European efforts seeking export restrictions for recyclables

- Fresh Perspective: Raj Bagaria

- Saica announces plans for second US site

- Update: Novelis produces first aluminum coil made fully from recycled end-of-life automotive scrap

- Aimplas doubles online course offerings

- Radius to be acquired by Toyota subsidiary

- Algoma EAF to start in April

- Erema sees strong demand for high-volume PET systems