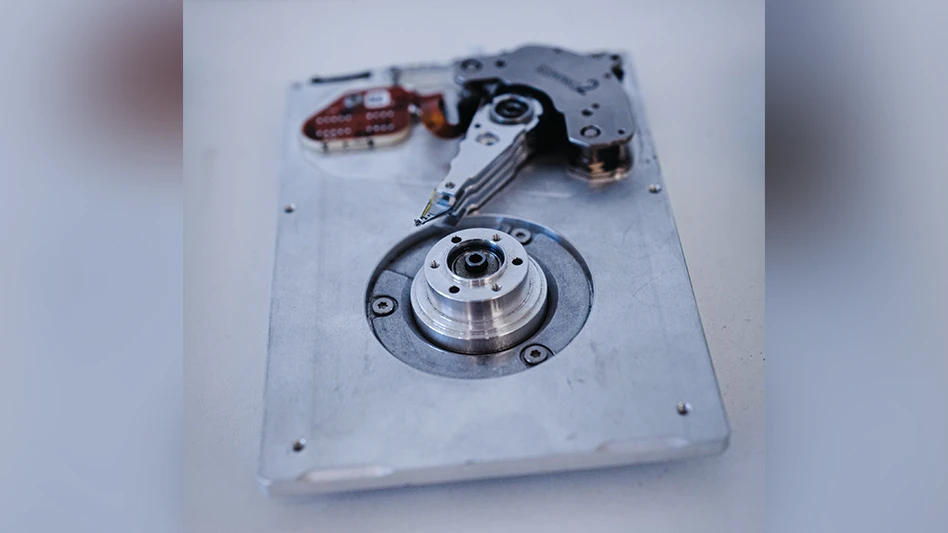

Image courtesy of Cyclic Materials

Cyclic Materials, an advanced metals recycling company headquartered in Toronto, has received an equity investment from Microsoft’s Climate Innovation Fund, an initiative dedicated to accelerating technology development and deployment of new climate innovations.

Cyclic says the investment is representative of Microsoft’s commitment to a circular economy and interest in hard drive rare earth element recycling.

For the past two years, Cyclic has developed a patent-pending technology, CC360, specifically to address the challenge of recovering rare earths contained in end-of-life hard drives. The company notes that while hard drives typically are sent to an IT asset disposal (ITAD) company at end of life, this disposal process is designed for data destruction, followed by shredding of drives for the recovery of other metals such as gold and silver.

RELATED: Cyclic Materials to supply recycled mixed rare earth oxide to Solvay

With CC360, Cyclic says ITAD companies can separate a portion of hard drives for rare earth recovery while retaining the rest of the hard drives for their traditional process. The separated magnets then can be processed by Cyclic’s processing technologies, unlocking an additional value stream from hard drive disposal.

“Microsoft is working to achieve zero waste across our direct operations, products and packaging by 2030,” Microsoft Climate Innovation Fund Senior Director Brandon Middaugh says. “This means adopting a circular economy approach. As demand for rare earth elements continues to grow in importance, we’re excited to support the creation of a sustainable supply of these materials with this investment.”

Established in 2021, Cyclic says it is developing technologies capable of economically, sustainably and domestically turning end-of-life products into valuable raw materials. The company adds that recycling rare earths delivers significant environmental benefits compared to mining processes, including a reduced carbon footprint and water usage.

Cyclic recently opened its Kingston, Ontario-based Hub100 plant, deploying its proprietary hydrometallurgical technology, REEPure, and helping fulfill the ever-increasing demand for domestic sources of mixed rare earth oxide (MREO) in North America.

“We have been working with Cyclic over the past few months to trial the use of the CC360 in our operations,” says Sean Magann, chief commercial officer at Chicago-based Sims Lifecyle Services (SLS). “We have seen tremendous performance improvements through the development and achieved throughput of one hard drive per second. This solution enables us to drive further value out of disposed hard drives, by reclaiming the critical rare earths, while maintaining the data security of the hard drives being disposed. An additional benefit is the reduction of magnets clogging our shredders. We look forward to deploying this technology across our operations.”

Cyclic co-founder and CEO Ahmad Ghahreman says Microsoft’s Climate Innovation Fund is an investor that is like-minded in creating a circular supply chain for rare earth elements contained in hard drives used in their data center operations.

“This support enables us to accelerate the deployment of our commercial facilities, which is a critical step in growing the domestic supply of rare earths in North America that support the energy transition,” he adds. “Additionally, we value the input that SLS has provided, helping us to validate our new CC360 technology that we believe will prove invaluable to large data center operators such as Microsoft as they work towards their circularity and sustainability goals.”

Latest from Recycling Today

- BMW Group, Encory launch 'direct recycling’ of batteries

- Loom Carbon, RTI International partner to scale textile recycling technology

- Goodwill Industries of West Michigan, American Glass Mosaics partner to divert glass from landfill

- CARI forms federal advocacy partnership

- Monthly packaging papers shipments down in November

- STEEL Act aims to enhance trade enforcement to prevent dumping of steel in the US

- San Francisco schools introduce compostable lunch trays

- Aduro graduates from Shell GameChanger program