Image courtesy of Coperion

Recycling equipment and technology vendors Coperion and Herbold Meckesheim, both based in Germany, will jointly present numerous product and process solutions for the compounding and recycling of plastics at Fakuma 2024, scheduled for Oct. 15-19 in Friedrichshafen, Germany.

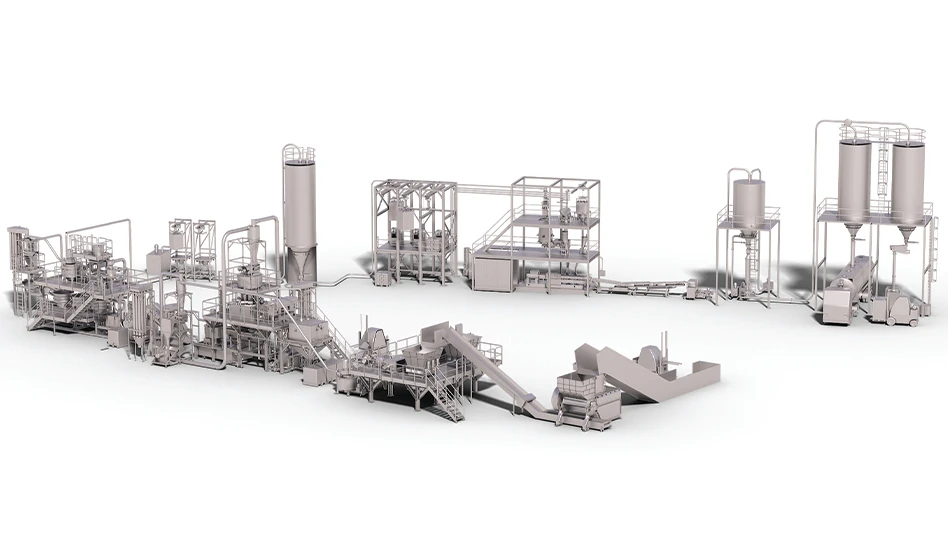

The equipment companies will demonstrate their expertise in realizing entire systems using virtual animation. Attendees at the international trade fair for plastics processing will be able to view both a complete compounding plant as well as an entire system for plastics recycling. The companies say the processes involved can be experienced digitally with the aid of simulations, and visitors will be able to look at individual components and their functions.

RELATED: Herbold, Coperion supply PET system in India

Additionally, rotors from Herbold granulators will be on display in various sizes and for a number of applications.

Along with individual components, Coperion and Herbold deliver entire systems for plastics recycling. From mechanical processing—shredding, washing, separating, drying and agglomerating of plastics—to bulk material handling, as well as feeding and extrusion and to compounding and pelletizing, the companies say their plants cover the entire plastics reclamation process chain.

Currently, the companies are developing an entire bottle-to-bottle recycling system for Indian preform and plastic packaging manufacturer Magpet Polymer Pvt. Ltd. The plant handles every process step, from the mechanical processing of polyethylene terephthalate (PET) bottles to discharging high-quality PET granulate, using a ZSK twin-screw extruder with fully attuned peripherals.

In their fully equipped test centers, Coperion and Herbold say they offer customers the ability to test a wide variety of plastic recycling processes and technologies under actual production conditions, even before investing. Herbold’s facility in Meckesheim, Germany, features a complete washing line for cold and hot washing, as well as size reduction solutions from shredders and granulators to pulverizers or plastic compactors for densification.

In 2023, Coperion launched the operation of its Recycling Innovation Center in Weingarten, Germany, with state-of-the-art, individually configurable recycling plants where material can be conveyed, fed, extruded, compounded, pelletized and deodorized.

Along with recycling, Coperion will present versatile and efficient uses of its ZSK and STS twin-screw extruders at Fakuma, as well as its feeding and conveying technologies for classic compounding tasks. With continuous research and development, the company says it continues to pursue its goal of setting new standards in machine and plant engineering for processing technology.

For example, the company introduced a reworked version of the ZSK 18 MEGAlab laboratory extruder at the beginning of this year. Coperion says that with its optimized design, the ZSK MEGAlab now offers even more flexibility and safety in handling. Using the newly developed, patent-pending feeding platform, up to four feeders can be placed over the extruder’s intake barrel with great variability, allowing ingredients to be added very flexibly into the compounding process.

Similarly, Coperion's ProRate Plus feeder line features new developments. With the ProRate Plus-MT twin-screw extruder and the new ProFlow bulk solid activator, an efficient feeding solution for powder additives now is available.

Latest from Recycling Today

- European project yields recycled-content ABS

- ICM to host co-located events in Shanghai

- Astera runs into NIMBY concerns in Colorado

- ReMA opposes European efforts seeking export restrictions for recyclables

- Fresh Perspective: Raj Bagaria

- Saica announces plans for second US site

- Update: Novelis produces first aluminum coil made fully from recycled end-of-life automotive scrap

- Aimplas doubles online course offerings