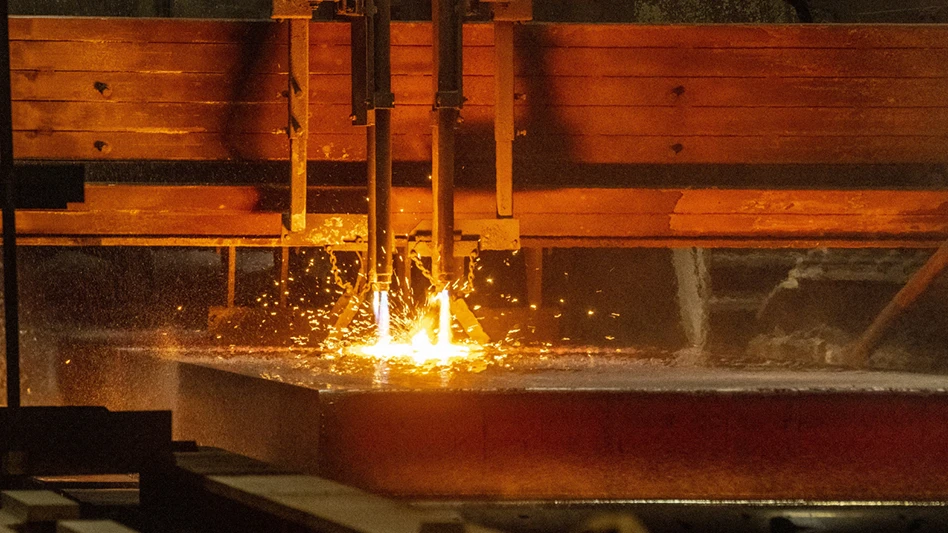

Photo courtesy of Cleveland-Cliffs Inc.

Cleveland-Cliffs Inc. has completed its acquisition of Stelco Holdings Inc., which operates blast furnace/basic oxygen furnace (BOF) steelmaking facilities in Ontario.

“The addition of Stelco enhances Cliffs’ position as the largest flat-rolled steel producer in North America, diversifies Cliffs’ end markets and expands its geographical presence in Canada,” according to the Cleveland-based firm in an early November announcement.

Cleveland-Cliffs says Stelco will continue operations as a wholly owned subsidiary of Cliffs, “preserving the name and iconic Canadian legacy of the business.”

“Today marks a transformative step forward for Cleveland-Cliffs," Cliffs President and CEO Lourenco Goncalves says. "By bringing Stelco into the Cliffs family, we are building on our commitment to integrated steelmaking and good paying union jobs in North America.”

Some steelmakers use the term “integrated” to describe operations that convert mined iron to steel or to refer to the process from metallics acquisition through melting in a furnace.

“This acquisition allows us to further diversify our customer base and lower our cost structure," Goncalves continues. "We are excited about the opportunities this acquisition brings and appreciate the warm welcome we have received from all government officials in Canada. We take our permission to operate very seriously and aim to continue the Stelco legacy with dedication and purpose.”

Wells Fargo, J.P. Morgan and Moelis & Co. LLC were involved in the transaction as financial advisors, while Davis Polk & Wardwell LLP and Blake, Cassels & Graydon LLP provided Cliffs with legal counsel.

The Cliffs acquisition of Stelco was announced this July. Subsequently, Cleveland-Cliffs announced this September it had lined up its funding for the Canadian acquisition and in October announced that regulatory agencies in Canada had approved the transaction.

Cleveland-Cliffs is a steel producer with a “focus on value-added sheet products, particularly for the automotive industry” and is vertically integrated from the mining of iron ore, production of pellets and direct reduced iron and processing of ferrous scrap through primary steelmaking and downstream finishing, stamping, tooling and tubing.

Latest from Recycling Today

- BMW Group, Encory launch 'direct recycling’ of batteries

- Loom Carbon, RTI International partner to scale textile recycling technology

- Goodwill Industries of West Michigan, American Glass Mosaics partner to divert glass from landfill

- CARI forms federal advocacy partnership

- Monthly packaging papers shipments down in November

- STEEL Act aims to enhance trade enforcement to prevent dumping of steel in the US

- San Francisco schools introduce compostable lunch trays

- Aduro graduates from Shell GameChanger program