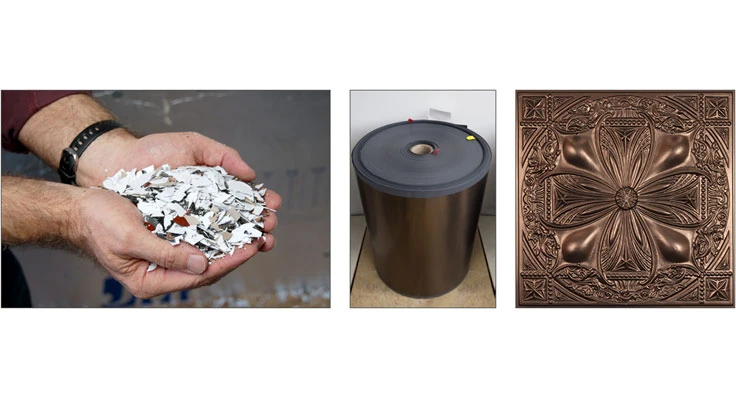

Ceilume says it has a 30-year history of continually striving to make its manufacturing process more sustainable, and these new, 98 percent preconsumer recycled tiles in faux tin, copper and bronze finishes are the latest step along that path.

Ceilume developed a way of turning manufacturing scrap into new tiles and panels. The leftover material from making the company’s products is carefully handled to insure cleanliness, fed into specialized granulators, resulting in confetti-like bits of plastic—a process that produces zero waste. This granulated material is then melted, rolled into a sheet and thermoformed back into tiles. After an ultrathin decorative laminate is applied, the end result is a ceiling that is more than 98 percent recycled.

“Plastic products of all kinds don't belong in landfills at the end of their usable life, they belong in new plastic products. Creating a finished product that contains 98 recycled material is the highest and best use for manufacture and customer-generated scrap,” says Ed Davis, president of Ceilume. “Plus,” he adds, “recycling is the right thing to do.”

Ceilume's panels are lightweight, acoustical and solve many architectural challenges, the company says. Thermoformed panels are not affected by water. This means panels can be installed before humidity has stabilized in a building, and dirty panels can be washed instead of replaced.

Compared with actual tin tiles, Ceilume’s thermaformed ceiling tiles are easy to install with little need for a plethora of tools or a lot of assistance during installation, it says.

According to the company, one of its customers said, “My family was very impressed with the ceiling we installed. We love the look and character it gives the room and how easy it was to install. My 14-year-old daughter and I finished the installation in just a couple of hours. The edge pieces were very easy to cut with scissors, and I'm looking forward to showing off the finished room over the holidays.”

Latest from Recycling Today

- Copper loses nearly 5 percent of its value in November

- Uplift360 targets niche materials recycling

- CAA submits final draft program plan in Oregon

- Steel recycling’s bright future not yet certified

- Cyclic Materials to supply Glencore with recovered copper

- NYSAR3 seeks respondents to commercial recycling survey

- Lithium battery prices decline in 2024

- Monadnock offers customizable, recycled-content papers