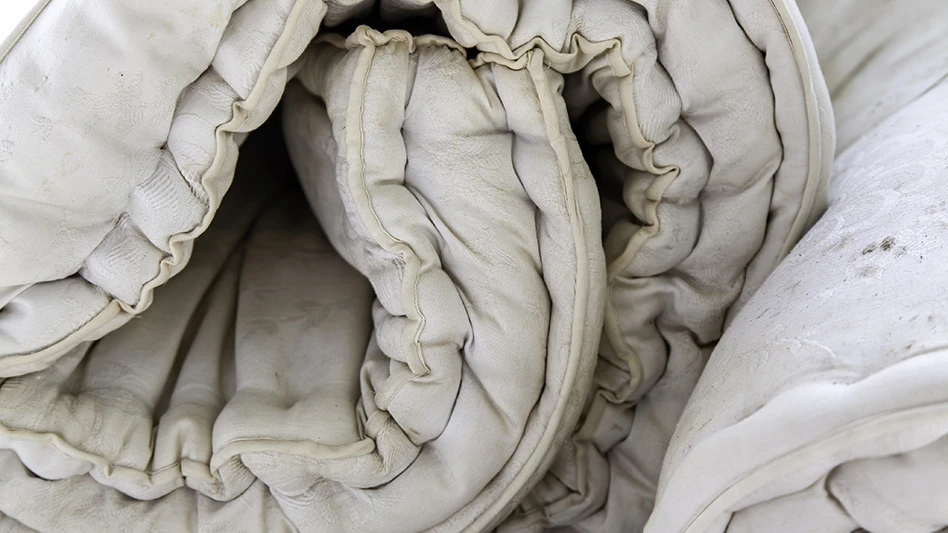

Photo courtesy of Butler-MacDonald.

Indianapolis, Indiana-based Butler-MacDonald has ordered a new plastic recycling and extrusion system from the Erema North America Inc. subsidiary of Austria-based Erema Group GmbH.

“The move was prompted by addressing what the company believes will be a future need to lower costs and be more effective at turn time,” says Scott Johnson, president of the 38-year-old plastics reprocessing firm.

“Since the inception of this pandemic, we were very proactive in putting all the recommended controls in place,” adds Johnson. “As a result, our employees remain healthy. Through April, we’ve been fortunate and minimally impacted by this pandemic and realized a significant increase in sales versus this period last year.”

Johnson says the increased demand may yet wane. “Beginning with May, we see things tapering off. A wide range of customers tell us they are struggling to overcome the losses experienced due to the extended stay at home orders, slower than anticipated reopening throughout the country and addressing the ‘new normal’ to reopen,” he comments.

“The economic impact of this, along with what’s coming next, will affect everyone for the foreseeable future, regardless of how well you’ve been doing. The best way we can address these mounting issues is to confront pricing, turn times and an ever-growing demand to process lighter weight difficult materials cost-effectively, all before the need arises.”

Butler-MacDonald says it serves a wide base of large and small customers in the cleaning of contaminated and mixed plastics; purchasing off-spec and cross-contaminated scrap; and selling many forms of rigid plastics used in the manufacture of goods, including medical, personal protective equipment and disinfectant/sanitizer packaging.

The company says its smaller customers are seeking price reductions to overcome the losses they are experiencing through reduced orders, downward price pressure and an overall decrease in consumption. Butler-MacDonald’s larger customers, meanwhile, are forcing price reductions as virgin resin prices fall, making it favored over reprocessed.

“It’s very important to us to keep material channels open and healthy,” says Johnson. “Recognizing profits drive everything, we are optimistic the customer base will stay committed to Butler-MacDonald’s service and continue [their] use of reprocessed material in place of prime virgin plastics.”

Latest from Recycling Today

- Alpla calls 2024 year of recycling growth

- Altilium says agreement puts it on lithium recycling path

- NWRA, SWANA partner to address lithium-ion batteries

- Corinth, Texas, renews waste contract with CWD

- Fresh Perspective: Sarah Zwilsky

- Plastics Industry Association announces leadership changes

- QCC celebrates 50th anniversary

- Venture Metals acquires 2 nonferrous processors