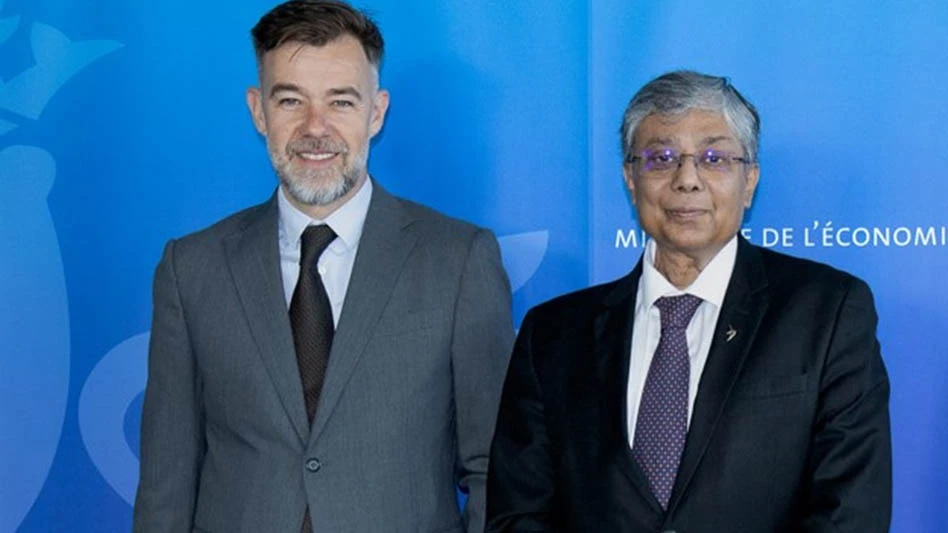

Photo courtesy of ArcelorMittal

Calling it part of its decarbonization process, Luxembourg-based steelmaker ArcelorMittal has confirmed its plan to invest in new electric arc furnace (EAF) production capacity at its Belval site in Luxembourg.

The investment is part of a series of projects that was the subject of a memorandum of understanding (MoU) signed last September between its ArcelorMittal Luxembourg business unit and the Luxembourg Ministry of the Economy.

That MoU confirms the willingness of the Luxembourg government to financially support an EAF investment, through various applicable aid mechanisms. In Belval, ArcelorMittal says that support will be worth approximately 15 million euros ($16.4 million).

ArcelorMittal says the Belval EAF will offer improved energy efficiency and an increase in steel production capacity in Luxembourg of almost 15 percent, reaching 2.5 million metric tons of steel per year.

“This project is the first concrete expression of the MoU that we signed last September [to] develop initiatives aimed at enabling ArcelorMittal’s Luxembourg sites to embark on the road to carbon-neutral steel production,” says Geert van Poelvoorde, CEO of ArcelorMittal Europe. “This is a major step forward in a project that has progressed quickly and demonstrates the Luxembourg government’s support for our decarbonization strategy.”

Rather than involving a conversion from blast furnace technology, as many recent EAF installations have been, the new equipment will replace an existing EAF that has operated since 1997. ArcelorMittal says the Belval steel plant produces many ranges of rails and niche products.

The installation of the replacement EAF in Belval will start this year with the goal of having it commissioned in 2025.

“The realization of this project is tangible proof that we are capable, in Luxembourg, of sustaining and developing our industry through a project that fits perfectly into the roadmap set by Europe to combat climate change," Luxembourg Minister of Economy Franz Fayot says.

“Thanks to the support of the government, we can make this progress in the modernization of our installations, to improve our operational energy efficiency and to make progress in reducing our carbon footprint,” adds Sanjay Samaddar, CEO of ArcelorMittal Europe Long Products.

Latest from Recycling Today

- Republic Services, Blue Polymers open Indianapolis recycling complex

- Altilium produces EV battery cells using recycled materials

- Brightmark enters subsidiaries of Indiana recycling facility into Chapter 11

- Freepoint Eco-Systems receives $50M loan for plastics recycling facility

- PET thermoform recycling the focus of new NAPCOR white paper

- Steel Dynamics cites favorable conditions in Q1

- Hydro starts up construction in Spain

- Green Cubes unveils forklift battery line