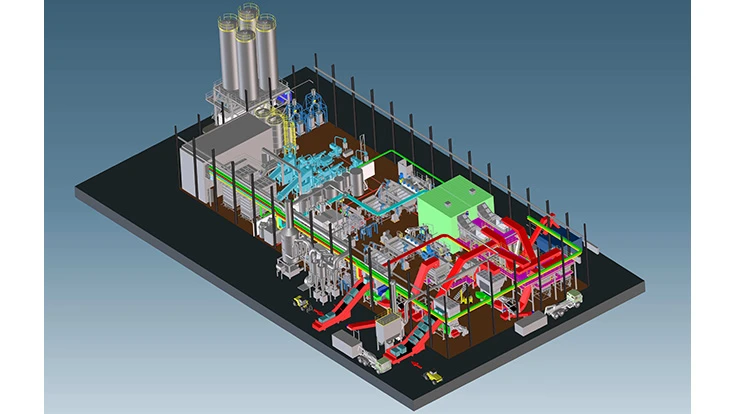

The Recycling Division of Novara, Italy-based AMUT sPa says it has been awarded tenders issued by two European companies to reclaim and regenerate thermoplastic polyolefin scrap to be transformed into granules. AMUT says both are “leading companies involved in the waste management field.”

The water-saving concept of the AMUT patented technologies “is well-known all around the world

because of the treated water that can be reused thanks to special recirculation circuits,” says AMUT.

For the first project, two lines will process, working in parallel, LDPE (low-density polyethylene) scrap with a total output of 2,500 kilograms (5,500 pounds) per hour. The thermoplastic scrap consists mainly of baled blown films coming from postconsumer recycled packaging.

To increase the flexibility of the plant, a group of conveyor belts will enable two shredders to alternately feed two buffers on the lines.

For the other project, AMUT will supply twin lines for washing and pelletizing of postconsumer

plastic materials: the total output is 1,500 kilograms (3,300 pounds) per hour of LDPE film or 4,000 kilograms (8,800 pounds) per hour of polypropylene (PP) or HDPE (high-density polyethylene) containers.

A distinct advantage is the possibility of reclaiming either light or heavy polyolefins with the same

machines installed in place, according to AMUT.

Latest from Recycling Today

- Fenix Parts acquires Assured Auto Parts

- PTR appoints new VP of independent hauler sales

- Updated: Grede to close Alabama foundry

- Leadpoint VP of recycling retires

- Study looks at potential impact of chemical recycling on global plastic pollution

- Foreign Pollution Fee Act addresses unfair trade practices of nonmarket economies

- GFL opens new MRF in Edmonton, Alberta

- MTM Critical Metals secures supply agreement with Dynamic Lifecycle Innovations