Image courtesy of the International Aluminium Institute

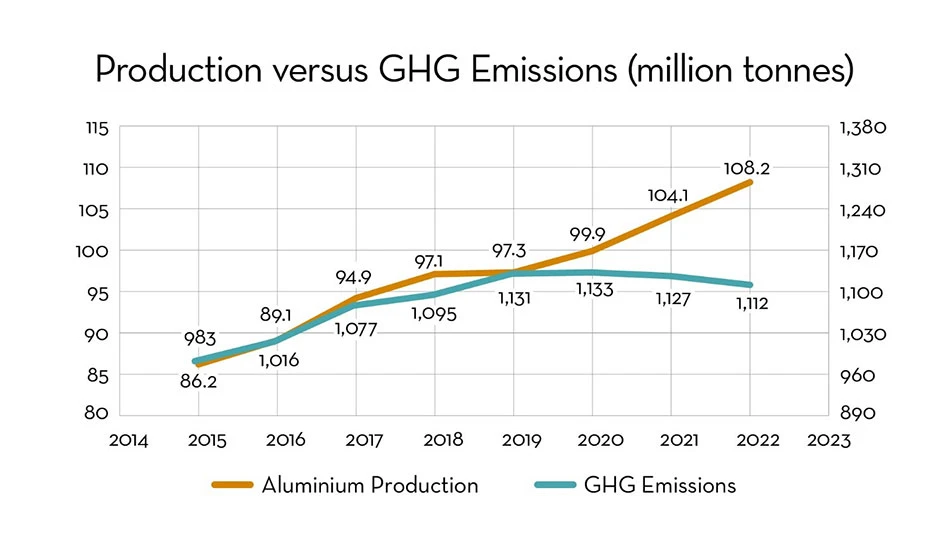

According to data from the London-based International Aluminium Institute (IAI), total greenhouse gas (GHG) emissions from the global aluminum sector did not grow despite growth in aluminum production. The association says this is the first time production increased without GHG emissions doing so.

RELATED: IAI backs aluminum emissions reduction target

According to the IAI, the last time the aluminum industry’s GHG emissions did not grow was in 2009; however, that coincided with a decline in production related to the global financial crisis.

Data from 2022, the latest available, show production grew by 3.9 percent from 104.1 million metric tons to 108.2 million tons. However, GHG emissions declined slightly from 1.13 billion metric tons of carbon dioxide equivalent (CO2e) to 1.11 billion metric tons of CO2e, and the GHG emissions intensity of primary aluminum production (the average quantity of emissions from the production of a metric ton of primary aluminum) has been declining since 2019.

In 2022, intensity declined by 4.4 percent from 15.8 metric tons of CO2e per metric ton in 2021 to 15.1 metric tons of CO2e per metric ton, the IAI says.

Aluminum has been touted as a key enabler to reduce emissions in other sectors, such as automotive, transport, building and construction and food and drink packaging. This opportunity is met by using primary and recycled aluminum, with primary aluminum production growing from 67.1 million metric tons in 2021 to 69 million metric tons in 2022.

RELATED: Report calls for revitalizing US primary aluminum manufacturing

“Our challenge is to reduce emissions while growing production,” IAI Secretary General Miles Prosser says. “Aluminum demand is expected to grow significantly over the decades ahead because of its role in decarbonization economywide. This will tend to drive increased emissions. But, at the same time, the industry is reducing the average emissions intensity of each [metric ton] of production.”

Prosser adds that the 2022 data show the aluminum industry’s success in reducing the emissions intensity of production. “While much remains to be done, 2022 was the first year that these intensity reductions offset production growth," he says.

"The transformation needed in the industry to meet global climate targets is much bigger than the early changes we are witnessing. Emissions reductions must be deeper, faster and more widespread, but for the first time, we can talk about heading in the right direction.”

He adds that if the industry continues to invest in and implement low-carbon energy sources and GHG reduction technologies, 2021 could be the peak of GHG emissions from the aluminum industry.

Sponsored Content

Labor that Works

With 25 years of experience, Leadpoint delivers cost-effective workforce solutions tailored to your needs. We handle the recruiting, hiring, training, and onboarding to deliver stable, productive, and safety-focused teams. Our commitment to safety and quality ensures peace of mind with a reliable workforce that helps you achieve your goals.

The industry’s reduction in GHG emissions is a result of investment in research, development and implementation of new technologies, innovative techniques and changes in energy supply, the IAI says, having tracked more than 50 projects across the industry that are contributing to this trend.

Of particular note are changes in the electricity supply used in aluminum smelting, the most significant component of the aluminum industry’s GHG emissions, the association adds. China, the world’s largest aluminum producer, has shifted toward using more hydropower, while other regions are embracing renewable energy, including the Middle East and Australia. Investments also are occurring in other key emission reduction technologies, including fuel switching in alumina refining and increased aluminum recycling rates and efficiency.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Latest from Recycling Today

- AF&PA report shows decrease in packaging paper shipments

- GreenMantra names new CEO

- Agilyx says Styrenyx technology reduces carbon footprint in styrene production

- SABIC’s Trucircle PE used for greenhouse roofing

- Hydro to add wire rod casthouse in Norway

- Hindalco to invest in copper, aluminum business in India

- Recycled steel price crosses $500 per ton threshold

- Smithers report looks at PCR plastic’s near-term prospects