Photo by DeAnne Toto

Processors and consumers of recovered aluminum and copper face a number of challenges, according to speakers at this year’s Bureau of International Recycling (BIR) World Recycling Convention & Exhibition, including the market volatility seen over recent months and regulatory changes that could affect the free trade of recycled metals globally.

“Supply and demand are not the only things that impact price in our industry,” said Paul Coyte, chair of the BIR’s Non-Ferrous Committee and managing director of F. Hayes & Co. in New Zealand.

One such factor is the role speculators have played in the rapidly escalating copper price.

“I don’t pretend to know anything different or better than you given what these markets have been going through over the last couple weeks,” said Edward Meir of London-based Marex, describing copper’s “meteoric ride up” in pricing on the London Metal Exchange (LME) and COMEX in recent weeks.

He attributed the recent price increase in copper to a combination of bullish factors, including mine-related issues that are suppressing copper production, investor sentiment that purchasing managers' indices were improving and central banks were going to lower bank-to-bank lending rates and growing demand for copper for use in electric vehicles (EV), power transmission and data centers, which he referred to as the artificial intelligence (AI) sector. This is particularly true of China, Meir said, where demand from these sectors has nearly made up for the collapse of the country’s property market, which once accounted for 20 percent, or roughly 5 million tons, of copper demand.

Meir said that when taken on their own, these factors did not have much impact; but, when combined with fund buying, they set off a “price explosion.”

“This month, a squeeze in the U.S. CME [Chicago Mercantile Exchange] contract led to even more fund buying before a correction set in this past week,” he said of the week of trading ending May 24.

He said funds account for more than 60 percent of client volumes as of 2015, which has made trading and hedging of physical copper difficult.

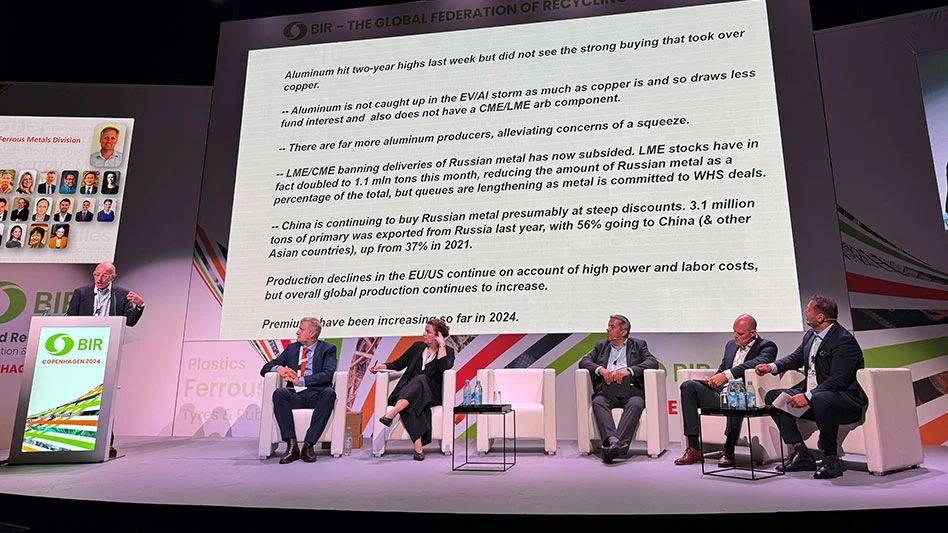

While Meir noted that aluminum hit two-year highs the week of May 20, it has not seen the strong buying that has affected copper in part because it is not as affected by the EV and AI markets and sees less fund interest as a result. Additionally, unlike copper, the white metal does not have a CME/LME arbitrage component. Concern of a squeeze in aluminum availability also is alleviated by the greater number of producers of the metal relative to copper, he said.

The higher prices for aluminum and copper have not brought more scrap to the market, Meir noted, adding that this illustrates how tight the markets are across their supply chains.

“People are even talking about $40,000 copper. I’m not sure that I’m there yet, but I wouldn’t rule anything out," he said.

This market volatility is one of many challenges facing recycled copper consumer Wieland, based in Ulm, Germany. But Andreas Fenster, Wieland's vice president of metals management, Europe, said the company’s main challenge is sustainability.

Wieland operates 41 sites in North America, 35 in Europe and nine in Asia, which include four smelting sites in the U.S. and two each in Austria and Great Britain.

Fenster said the company’s customers are demanding sustainability, with 271 asking Wieland for CO2 and recycled content numbers in 2023—a 400-plus percent increase from the previous year.

The company’s metallic raw materials account for most of its carbon footprint, and using more recycled content is the main lever it has to reduce this. Therefore, Fenster said, Wieland is aiming to increase its recycled content to more than 90 percent to help it achieve net zero emissions by 2045. In the U.S., Wieland will open its plant in Shelbyville, Kentucky, in June, which will allow it to consume lower-grade copper scrap, such as birch/cliff. Wieland also plans to electrify all its plants and use renewable energy exclusively to lower its Scope 1 and Scope 2 emissions.

Other challenges Finster discussed were CBAM, or the carbon border adjustment mechanism, which is designed to prevent the relocation of production to regions with less ambitious climate targets and measures outside the European Union by taxing imported goods. It affects all companies in the European Union that import iron, steel, cement, aluminum, electricity, fertilizers and hydrogen.

The German Supply Chain Act, or Lieferkettensorgfaltspflichtengesetz (LkSG), is another challenge Wieland faces.

“The word sounds complicated, and it is,” Finster said of the German pronunciation of the law, which requires companies to analyze all their Tier 1 suppliers and assign corrective measures or agreements with suppliers where violations of human rights occur or environmental protection issues have been identified. LkSG is expected to be replaced by the recently passed European Union’s CSDDD, or Corporate Sustainability Due Diligence Directive (CSDDD) law, which he said is “even more complicated,” starting in 2027.

Finster said laws, specifications and regulations are important but vary considerably around the world, which leads to distortions that affect companies’ competitiveness.

Christian Bonnicksen, project manager of nonferrous for Denmark-based HJ Hansen Recycling Group, said that company has approached the volatility of the recent market by buying as much as possible and selling it as quickly as possible at a margin. “We need to focus on this and not if copper is going up or down,” he added.

The BIR and the recyclers it represents advocate for free and fair trade, with Murat Bayram, managing director of U.K.-based EMR noting that while recyclers would prefer to choose a neighboring smelter to ship material to, their demand is not always consistent, necessitating exporting.

Meir noted that regionalization has emerged in the trading of nonferrous recycled materials.

“Free trade sounds great in theory, but governments are becoming more and more protectionist,” he said, citing the rise of tariffs. “Scrap is a very sought-after import across the world,” with more barriers being erected “to keep it ringfenced inside geographies.” He noted governments moving away from free trade threatens the recycled materials industry.

“Everyone benefits from the carbon savings if the scrap can travel around the world,” Coyte added.

When asked by an attendee to provide hedging advice, Meir quipped, “Don’t pick up the phone,” before adding that as more material comes to the U.S., that will dampen the arbitrage. He said companies might have to move positions forward so that they are not stuck in the backwardation. “It’s one thing to hedge, but we need physical suppliers to honor their contracts.”

In the area of CO2 reductions and the role that recovered metals play, Bayram said recyclers need to be louder and more visible by participating on CO2 certificates.

“Now is the time to stand up and show ourselves or people will create the next bureaucratic monster for our industry. We need to go to Brussels in one big vessel rather than paddle in our own boats,” he said of recyclers, consumers and equipment suppliers.

The BIR World Recycling Convention & Exhibition was May 27-29 in Copenhagen at the Bella Center.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Latest from Recycling Today

- ReMA opposes European efforts seeking export restrictions for recyclables

- Fresh Perspective: Raj Bagaria

- Saica announces plans for second US site

- Update: Novelis produces first aluminum coil made fully from recycled end-of-life automotive scrap

- Aimplas doubles online course offerings

- Radius to be acquired by Toyota subsidiary

- Algoma EAF to start in April

- Erema sees strong demand for high-volume PET systems