Red-hot metal pours from a furnace, creating a halo of sparks as it lands in a mold. Across the plant, acid solutions dissolve precious metals in specialized tanks.

“No place for a lady,” a person of a certain era or mindset might describe the North Carolina plants where precious metals recycler Metallix mines scrap materials for gold, silver, platinum, palladium and rhodium.

That person should probably steer clear of Eric Leiner, owner of Shrewsbury, New Jersery-headquartered Metallix, and the 27 women who work for his company.

Leiner only recently started to think about the number of women who work at Metallix. “I was at an industry event when I looked around the room. Of the 100 or so people there, only five were women,” the second-generation owner of the company recalls. “It was such a stark contrast to Metallix,” he continues. “I’ve always hired the best person for the job. In my case, many of them just happen to be women.”

In September, Leiner promoted then-Vice President Maria Piastre to president of Metallix, making the 37-year-old one of only a handful of female executives in a squarely male-led industry.

Leiner says his company’s equal hiring practices aren’t attempts to buck a system or make a splash. “They’re simply good business decisions.”

These decisions have led to a fascinating cross-section of positions occupied by women under Metallix’s roof, all contributing in unique ways to the company’s growth and success.

Challenging work

At 24, DiQuisha McCoy is the youngest employee at Metallix’s Maxton, North Carolina, processing plant, yet her role lies at the heart of the facility’s function: She operates decanning machines that crack open catalytic converters’ metal shells to access the precious metals inside.

It’s not idle work.

“It takes a lot of physical ability to operate my machine, crush the scrap materials and collect it all in scrap bins,” McCoy says.

Operating a large decanning machine isn’t a career McCoy knew about growing up—let alone imagined she’d spend her days mastering.

“I always wanted to work with money—maybe in accounting. But after graduating high school, I looked at my mom and said, ‘I don’t know if accounting is what I actually want to do.’”

She landed a position as a press operator for an auto manufacturer, cutting out car parts and testing parts for four-wheelers. It gave her the experience necessary to apply for a position running Metallix’s decanning machines, which require a keen understanding of the various converter types that come into the plant.

This knowledge isn’t even the toughest part of her job.

“You have to stay constantly busy—less talking, more working,” McCoy says. “I process at high speed; I just get on my machine and run it. Timing is key. The hardest thing for me here is the pace.”

But the pace is not hard enough to send her packing.

“My supervisor knows he can rely on me because I never say no. I love a challenge.”

Not in the forecast

Tara Bradley has been fascinated by meteorology for as long as she can remember. From estuaries to atmospheric patterns, the science whiz relished any chance to think critically about weather and had planned on a career doing exactly that.

But after four years of intensive undergraduate study, Bradley stumbled upon Metallix in 2012 and landed a position as a lab technician. She discovered a lot to love within another environment: precious metals recycling.

“Critical thinking is key,” Bradley says. “You rarely encounter the same thing twice. And there’s excitement about every lab sample that comes through the door.”

In her initial role as a lab technician, Bradley handled the acid digestion of precious metals once they emerged from the fire assay.

“I liked seeing the precious metal fall out of solution samples during the acid digestion process,” she says. “Then I’d report the results of that sample to my superior. A lot of people are waiting for that news. It was all very exciting.”

Last year, Bradley was promoted to lab manager. Then, this past summer, Metallix handed her the keys to its new testing and analytics lab. As lab manager today, with a full staff to oversee—and with thousand-degree furnaces, potent acids and sensitive instrumentation under her watch—there’s no question where her affections are.

“This department is a mix of every science,” Bradley says. “There’s some chemistry, some biology, some physics [and] some calculus; I’m obsessed.”

Welcoming atmosphere

“My last job was a good old boys’ network,” says Tracy Montour, Metallix solutions manager. “If you were female, you weren’t in the ‘club.’”

Her official title might not make Montour’s duties or importance readily apparent: She and the five men who report to her manage Metallix’s chemical refinery, producing gold, silver, platinum and palladium.

Dissolution, separation and recovery of precious metals from cyanide and acid solutions put Montour’s chemical engineering degree to use every workday.

The high-risk nature of her department forces Montour to exercise her judgment daily, too. Her team routinely uses harsh chemicals under pressure to recover every trace of precious metals as quickly as possible. It means every action, from rushing to meet a company deadline to carrying trays of precious metals, must be executed through the careful, calculated lens of safety first.

“Getting materials completed, getting it done on time, hearing the supplier is happy and doing it all without incident—that’s the goal,” she says.

In terms of fitting in with her all-male team? Montour has found a winning formula at Metallix on this front, too. “They’re very respectful of me. I appreciate it.”

Getting her hands (and face) dirty

Some people listen to music while working. Nina Daniels prefers the sweet sounds of a refinery operating in full swing.

“I love working at the refinery,” Daniels, an outside sales representative, says of her desk inside Metallix’s Greenville plant. “Having a desk overlooking the refinery is helpful to me as a sales rep because I get a front-row seat and see how it all works.”

Ten days or so each month, Daniels steps away from her desk to meet clients and prospective clients all around the United States. The goal? Bringing their manufacturing scrap back to Metallix for processing and appraisal. But even her off-site sales work teems with reminders that this isn’t an industry for those unwilling to get their hands dirty. Daniels routinely swaps loafers for boots that let her climb under machines to scour hidden places where valuable metals might linger.

“On one of my first sales trips for Metallix,” she says, “I leaned up on a plating tank. By the time I got back to my hotel, residue had eaten a hole across the back of my suit!”

Another time, Daniels brushed her face with her hand after touching silver nitrate, forgetting that the compound leaves a dark gray color that lingers for four to five days.

Those rookie mistakes were a testament, she says, to the complexities of the precious metals industry—an industry she knew nothing about before she was hired by Metallix in 1998. The learning curve was steep. The stakes sometimes felt steeper.

“Some of the scrap materials we solicit are worth hundreds of thousands of dollars,” Daniels says. “It’s an extremely competitive industry, and a supplier is not going to give those materials to just anyone who walks in the door. I know that to win the account, I have to be knowledgeable about the client’s business, their materials and our processes. I have to show I’m qualified to handle their account and I stand out from our competitors.”

Taking the lead

“I had never heard of precious metals refining,” Maria Piastre says. “I didn’t know the industry existed.”

That was only 12 years ago. Piastre was a 25-year-old assistant publisher for an industrial magazine, and she hated it.

“I was searching for a job when I saw Metallix’s ad,” Piastre says. “Eric was looking for someone from Latin America to work in inside sales.”

Born and raised in Colombia, Piastre applied and interviewed for the job, working hard to parlay manufacturing insights she’d picked up at the trade magazine, including information on where everything from gold-plated connectors to solar industry products were made, into impressive interview responses.

She arrived for what she thought was a second interview to a job offer.

“Maria’s strategy worked because I offered her the position and was glad when she accepted,” Leiner says.

Immediately, Piastre thrived.

“I started learning the business and falling in love with it,” she says. “I’m so fascinated by what we do.”

Eager to learn more and assume additional responsibility, Piastre steadily moved up the ladder. She brought in new business, developed good relationships with industry partners and participated in and pushed for improvements within the company.

Twelve years later, Piastre is Metallix’s newly appointed president.

“I am honored to have been promoted as president of the company,” she says. “Did I think I was going to become Metallix president when I was hired? Absolutely not. All I know is that I embraced that first job at Metallix with a lot of passion and responsibility, always hungry to learn more and do a good job for the company. Today, 12 years later, I am taking this new role as president with the same passion and the same ambition to do a good job.”

Piastre continues, “Being the president doesn’t mean that I know it all or that I can stop learning, it doesn’t even mean that I reached anything. It means that I must continually increase my commitment to learning and that I must work intensely to lead the team into reaching new heights together.”

While a female president might come as a surprise to some, to Piastre, such judgment is a nonstarter.

“What I bring to the table has nothing to do with gender,” she says. “I know what I bring to the table, which includes experience, a willingness to learn and a lot of passion for this business.”

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

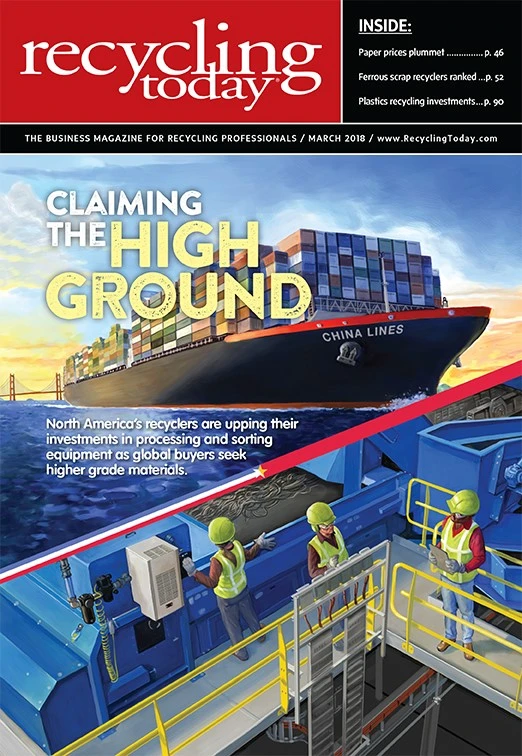

Explore the March 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- GFL opens new MRF in Edmonton, Alberta

- MTM Critical Metals secures supply agreement with Dynamic Lifecycle Innovations

- McClung-Logan Equipment Company joins Tana’s authorized dealer network

- Grede to close Alabama foundry

- Plastics Recycling Conference 2025: Working toward their targets

- SWACO rolls out new commercial recycling and food waste programming

- Updated: Matalco to close Canton, Ohio, plant

- Metso launches electric Anode Weighing and Casting Machine