Chopping lines

In the world of nonferrous wire and cable processing, SWEED continues to carve a niche by seamlessly blending standard and unique applications with high-performance and superior recovery as well as continuing to push boundaries and introducing cutting-edge products and innovations to the industry.

Beyond the chopping line

SWEED’s wire chopping lines are meticulously designed for maximum recovery of copper and aluminum from sorted or mixed insulated wire (ICW/IAW), ACR, ACSS, Reda cable and much more. Its exclusive line of linear scrap choppers, paired with a roster of single-shaft shredders and a comprehensive offering of downstream processors, makes SWEED a versatile and unique equipment provider.

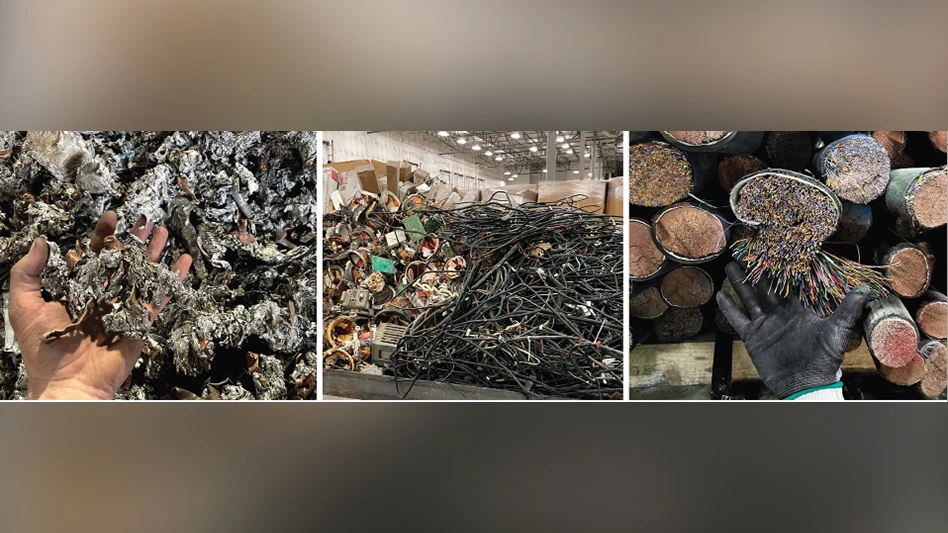

SWEED’s recent body of work in bulk processing includes installations for a diverse mix of materials. In less than a year, it has implemented systems for recovering low-grade copper and aluminum from e-scrap, extracting copper from telecommunication cables, the customary blend of low- and high-grade ICW and a two-system setup for mixed low-grade ICW and birch/cliff. The next system, expected to be commissioned in August, will serve a demolition company, further expanding SWEED’s presence in nonferrous recycling. These intelligently designed systems optimize recovery while minimizing operator requirements, aligning with SWEED’s goal of achieving the lowest operating cost per pound.

Innovating for customers

Innovation is at the core of SWEED’s DNA. To round out its single-shaft shredder offering, SWEED recently introduced the 125-horsepower single-shaft prechopper, a versatile unit designed for use in multiple applications. With a larger knife profile and significantly higher capacities, it serves as a primary processor for midsize applications and acts as a secondary processor when multiple preprocessing steps are required. The product release has been a success, with five units shipped to customers within the last nine months.

What started as a custom addition to a large downstream aluminum recovery system has become SWEED’s standardized solution. It has designed and built a footprint-friendly surge bin for metering material, ingeniously built on top of its air-separation tables. This all-inclusive separation assembly supports one- and two-table setups, making it ideal for high-volume applications while optimizing the table’s performance, ensuring the best purity results.

SWEED also updated its product offering with the introduction of a 75-horsepower turbo mill, designed for low-grade wire applications and prepping material to optimize recovery. The new turbo mill, equipped with designs for small and large volumes, bolsters SWEED’s product line to cater to customers considering an upgrade from their starter system.

Finally, SWEED is unveiling its new S2000, a modular starter system designed specifically for customers looking to enter the wire chopping sector. This user-friendly system sets the stage for success, providing an ideal entry point into the world of chopping, and is built and supported in the U.S.

Testing lab

Recognizing the importance of making informed decisions, SWEED provides a wire chopping test system at its headquarters in Gold Hill, Oregon. Running samples through this system provides critical insights into system requirements and design, assisting customers in making the correct capital investment decisions.

SWEED Machinery is committed to an ongoing journey of innovation to ensure maximum recovery, the lowest operating costs and system longevity. Experience the power of its wire chopping lines and linear chopping systems and witness how SWEED is redefining the recycling landscape. Contact SWEED today and embark on a sustainable future where copper and aluminum recovery reach new heights.

Explore the September 2023 Issue

Check out more from this issue and find your next story to read.