The role recyclers play in facilitating organizations’ sustainability goals can be core to their success; however, an organization must be committed to sustainability so it can shift its focus away from waste management and toward discarded materials management.

The term “waste management” can lead to a certain way of thinking encompassed by the term itself, which places waste at the forefront. When organizations start with the belief that materials are waste, it is less likely that they will view the materials as recyclable. Generators likely tend to think of waste first because the waste management industry makes it easy to throw materials away. This way of thinking has a tendency to hinder the ability to drive companies’ sustainability plans forward.

Once this traditional perception is challenged, clients begin to view discarded materials not as waste but as materials that should have positive end-of-life solutions.

IMPROVING THE OUTCOME

Once generators realize discarded materials are not waste, they begin to consider implementing programs that allow them to understand what discards they are generating, where these materials are being generated and how to collect them efficiently and effectively. This leads to more materials being recovered, increasing diversion rates and reducing the amount of waste heading to landfills. It also reduces the costs associated with managing that waste.

Within these organizations, sustainability leaders take on the task of analyzing each aspect of their internal processes. Working with these leaders, a material recovery/recycling company can play an important role in developing recovery programs and assisting in bringing recycling to the forefront of these organizations.

As new widgets are added to organizations’ processes, their sustainability leaders and their material recovery/recycling partners are continually re-evaluating the programs to ensure each new widget can be collected and recycled.

Not all materials will have a positive end-of-life solution, however. As organizations become more engaged in the circular economy, they will transform themselves into circular organizations. This will drive organizations to rethink the design of their products and packaging and, when possible, make changes to ensure that what is produced or used in their products results in a positive end-of-life solution. And only when all else fails will that discarded material become waste.

ANALYZING THE STREAM

At Cascades, our Recovery … Plus program is designed to give organizations that generate discarded materials a one-stop solution to meeting their sustainability goals. Recovery … Plus takes generators through a five-step process intended to quantify, document and validate data for sustainability reporting and move them toward being sustainable organizations.

The first step in the process is the discovery phase. Here we listen to the generator’s wishes and pain points and note the areas the organization has targeted for improvement with regard to the existing waste management program. We discuss Cascades’ philosophy, vision and process for discarded materials management, and together we determine if there is an appetite to move forward with the process.

Step two involves an in-depth analysis of discarded materials and processes at the client’s site. Recovery … Plus experts detail the discarded materials to be recovered, process efficiencies, diversion potential and cost savings that can be realized through the program. During this phase of the project, we compile volume, flow and commodity data on all discarded materials generated with a focus on positive end-of-life solutions. The data we compile allow us to prepare a comprehensive discarded materials management plan for the client.

Once volume, flow and commodity data are gathered and considerations for material procurement and product manufacture are factored in, we create the cost-benefit scenarios associated with moving discards from the waste management stream to the recovery stream. We track a number of key indicators by material or programming change before, during and upon successful implementation of the recovery program. Some key indicators include diversion rates, unrecoverable discarded material volume and cost/revenue position. Each of these indicators is used to allow Cascades to build a benchmark for the organization and to identify the expected outcomes.

Cascades Recovery provides all necessary equipment and logistics needed to implement the program, as well as ongoing support and resources for a client’s employees, including training and education, to ensure the program is achieving the stated objectives.

Clients’ programs are monitored on an ongoing basis, and regular waste audits and diversion reports are provided.

In an environment of increasing disposal costs, legislative pressure in terms of regulations and disposal bans and the desire to create a circular economy, the benefits of moving materials from the waste stream to the recovery stream are clearer and easier to justify. However, the cost of implementing such a program cannot be underestimated. As much as an organization shows a willingness to change, discarded materials management must be sustainable and make a positive contribution to performance.

THE END GAME

Recovered materials require end markets. In many cases well-established markets for discarded materials are readily available; but, when there are none, organizations rely on us to develop end markets and to secure consistent movement of materials. At times, it is as simple as being able to consolidate small amounts of materials generated by many producers, making it attractive for an end user to take an interest in the material. At other times it may require investing in technology or processing systems before a material can realize a positive end of life. As a material recovery/recycling/producer company, we recognize this as our role in the sustainability services supply chain.

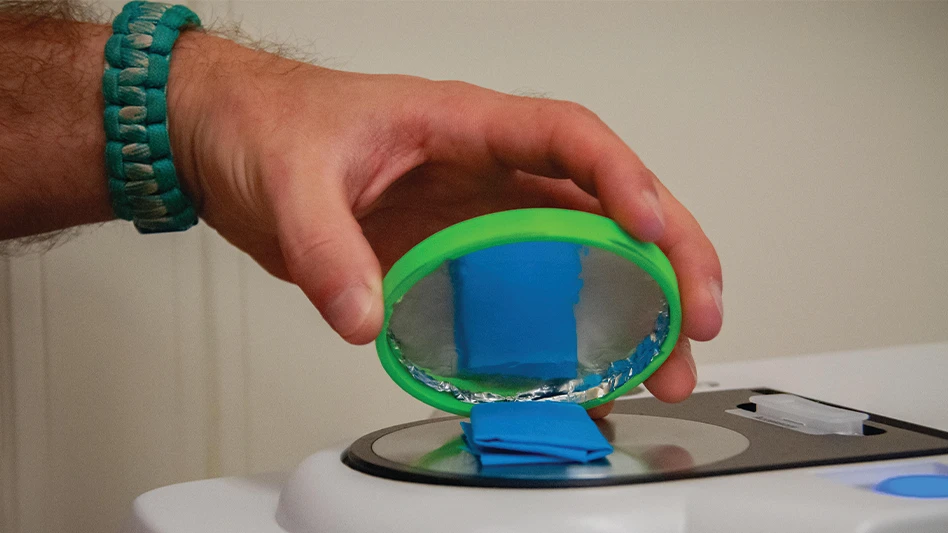

For problematic materials, we engage our clients’ purchasing and design departments to explore options that allow more consistent and more recyclable commodity packaging and design options to allow for improved or increased recyclability in the marketplace. Often something as simple as an education/information session for purchasing can make a substantial difference in the commodity stream entering a recycling facility and, therefore, the recyclability of the inbound packaging. Consistent recoverable materials make internal recovery program design and operation simpler and more successful. Similarly, educating product design teams as to the recyclability of materials and how those materials are collected and processed can have a significant impact on product procurement and product packaging design.

The next steps in the process are to prepare, communicate and implement the recovery options generated through the cost-benefit analysis and to manage the process on an ongoing basis. By taking a hands-on approach, we provide the organization whenever possible with collection and postcollection services. This alignment ensures the outcome of the generator’s activities will yield the highest value and rate of success.

Cascades is in a unique position. As a circular company, we rely on secondary materials to make our paper and packaging products. Our Recovery division plays an important role in securing and preparing the materials we need to make these products. Being a vertically integrated organization, Cascades has the ability to take recovered materials full circle by remanufacturing them into new products. In many cases, these products are purchased by the organization that supplied the raw materials used to make them. This demonstrates to the generator that they can make a difference as a member of the circular economy. Cascades’ ability to fully execute this process for generators gives them the confidence to trust in the process.

Sustainability within organizations will become common in the future as the circular economy concept gains momentum. Organizations will be evaluated on their performance and values by setting targets that respect the planet, people and prosperity.

As a collector, processor and consumer of recovered material, the outcome of any program we install is as vital to us as to the generator. Cascades realizes the benefit of ensuring that each recovery program is implemented correctly and delivers the desired material stream in the desired collection manner to the end market. In most cases, source-separated recoverable materials lead to a less costly and more successful discarded materials management program for both the generator and the recycler.

MEASURING SUCCESS

Once discovery, analysis and implementation are completed and management is underway, we need to be able to measure our success. Without the ability to measure our progress, we cannot properly quantify the savings associated with these discarded materials management activities. Proper measurement allows all parties to evaluate the success of the program to date, as well as future opportunities.

Various tools can be used to measure program success. Different generators or generator situations will benefit differently from these various methods of evaluation. Measurement tools such as diversion reports, capture rates, generation rates, facility assessments and waste analyses all can contribute to sustainability reporting and provide a clear picture of the success of generators’ discarded materials management programs. Regularly scheduled meetings to review reporting, monitor progress metrics and target/implement areas of opportunity play an important role in program success.

As we move toward a landscape with more recovery bins than waste bins, we will encourage a “Green by Nature” environment where discarded materials will be recovered knowing they were made with a positive end-of-life solution in mind. This will lead to a greater, more predictable recovery stream that will stimulate investment and creativity, leading to better outcomes for discarded materials.

The material recovery and recycling sector will be at the forefront of ensuring organizations have the services and tools necessary to meet their sustainability goals.

Sustainability within organizations will become common in the future as the circular economy concept gains momentum. Organizations will be evaluated on their performance and values by setting targets that respect the planet, people and prosperity.

Since its founding, Cascades has believed in producing paper and packaging with the environment in mind. As we focus on our future, we realize the benefits of a circular economy and are committed to investing in producing our products with a positive end of life and continuing to play a critical role in growing our efforts to recover the products we produce.

Explore the April 2016 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Singapore researchers develop flame retardant removal process

- Norsk Hydro buys remaining shares of Hydrovolt

- The Scrap Show: Dhawal Shah of Metco Ventures LLP

- AEPW releases new mechanical recycling ‘playbook’

- Nucor to expand downstream products capacity

- APR launches Recycling Leadership Awards

- Private equity firm announces majority investment in Sprout

- Author predicts spike in silver’s value