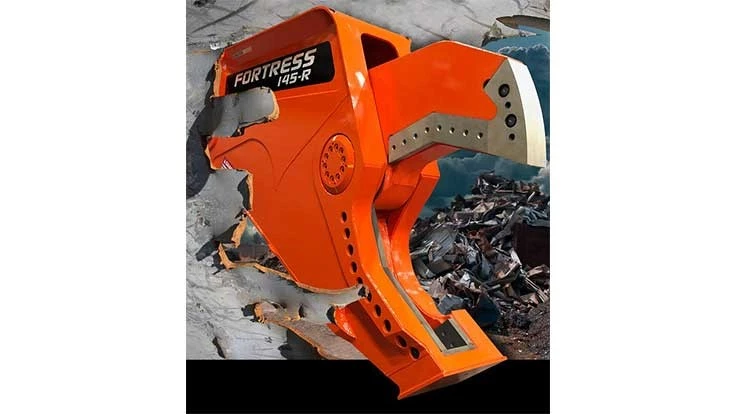

Superior, Wisconsin-based ShearCore, a division of Exodus Machines, has introduced the FS145 mobile shear. The company says it is the largest mobile shear in its product line of attachments for the demolition and scrap recycling industries.

“The FS145 shear has been designed with less welds, fewer pieces and is structurally stronger,” says Ross Christenson, the lead designer of the FS145.

“The new FS145 shear model is the culmination of the company’s design policy of ‘begin every design with a foundation in experience and a desire to improve,’” says Bruce Bacon, president of Exodus. “This shear model exemplifies that policy with a new tip design to handle the massive force this shear delivers.

“A new shark fin rear lug design transfers stress in a new and improved method over any previous design in the mobile shear world, which allows higher forces to be distributed over greater mass,” he continues. “What this means to the customer is that this shear punches above its weight class. [This is a] big advantage in the steel processing world.”

The FS145R, the rotating model, has a weight of 28,000 pounds with a jaw opening of 46 inches and jaw depth of 47 inches, along with a reach of 14 feet and 9 inches. The minimum excavator boom mount is 145,000 pounds with a minimum excavator stick mount of 250,000 pounds. The FS145 also is available as a nonrotating model.

ShearCore says the release of the FS145 brings its Fortress mobile shear line to eight different models, including the FS25, FS35, FS45, FS55, FS75, FS85 and FS95. The Fortress line also includes the concrete processor cracker series.

Latest from Recycling Today

- Aqua Metals secures $1.5M loan, reports operational strides

- AF&PA urges veto of NY bill

- Aluminum Association includes recycling among 2025 policy priorities

- AISI applauds waterways spending bill

- Lux Research questions hydrogen’s transportation role

- Sonoco selling thermoformed, flexible packaging business to Toppan for $1.8B

- ReMA offers Superfund informational reports

- Hyster-Yale commits to US production