Celebrating 100 years in business is a milestone enjoyed by only a tiny fraction of the companies that enter and leave the arena of commerce on a daily basis.

Celebrating 100 years in business is a milestone enjoyed by only a tiny fraction of the companies that enter and leave the arena of commerce on a daily basis.

When Russian immigrant Jacob Solotken started collecting scrap materials in Indianapolis in 1914, he began a journey that succeeding family members are still traveling 100 years later.

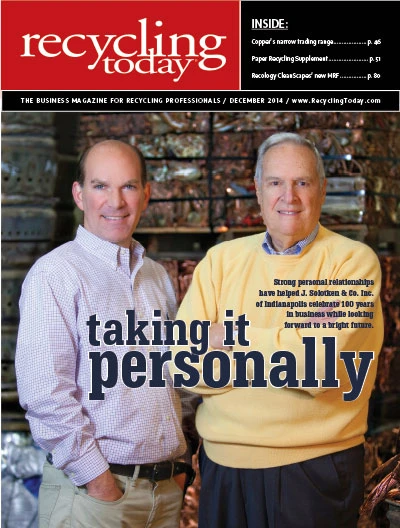

2014 marks a 100th anniversary for J. Solotken & Co. Inc., a scrap metals processing and trading firm located in Indianapolis just a few miles from where Jacob started out. Jacob’s grandson Joseph Alpert, current president of the company, and Joseph’s son-in-law Brian Nachlis, vice president, say the company has changed in numerous ways during that 100-year span while also staying faithful to a core value and philosophy that the scrap business is based on cultivating and maintaining personal relationships.

A late surge

The company Jacob Solotken founded took root in a central Indianapolis neighborhood on land that is now part of a university campus.

“He started the company literally with a pushcart,” says Alpert, who adds that an initial sign of progress for the company was when Jacob could afford a horse and carriage.

The enterprise became a family business in 1937, when Joseph’s father, Harry Alpert, joined J. Solotken & Co.—and remained part of it for 57 years.

Leo Selig, Jacob’s brother-in-law, was another long-time company employee, and they were joined by Joseph Alpert in 1969. Joseph has now been a part of J. Solotken & Co. for 45 years.

The scrap company moved its operations to a warehouse on South Harding Street in Indianapolis in 1936 and remained in that same building for nearly 75 years.

The structure helped house a business that endured the tail end of the Great Depression, World War II and numerous business cycles capable of shutting the doors of less carefully managed companies.

After several decades of service, however, it became clear to Alpert and Nachlis that a facility upgrade was necessary. “We were operating in a four-story brick building with freight elevators, wooden floors and narrow aisleways,” says Nachlis. “We did not have the space for modernized processing equipment.”

In 2010, J. Solotken & Co. Inc. moved into a 180,000-square-foot plant and office that had formerly served as a warehouse for finished metals distributor Ryerson Steel.

Alpert and Nachlis say the decision has yielded numerous and immediate benefits to the company’s operations. “The efforts we formerly had to make to process scrap were totally inefficient,” Nachlis says. “It would take us two hours to make a 500-pound bale of aluminum siding. We would have to fold siding before we put it in the pit baler. We would have to run the baler five times before we made the finished bale and then hand-tie it and push it out. We did it that way, and we survived,” he comments.

“Now, along with the new building, we have a new two-ram baler with a conveyor system,” Nachlis adds. “We have three briquetters, four shaker tables and we installed a wire chopping system in February 2014.”

Alpert says he had confidence to make the major investment in new plant space (during the severe downside of another business cycle) largely because of the addition of Nachlis to the executive team.

A career move

Nachlis was Alpert’s son-in-law several years before he became his vice president at J. Solotken & Co. “Joe has two daughters, and I am married to the older one,” explains Nachlis.

Nachlis was Alpert’s son-in-law several years before he became his vice president at J. Solotken & Co. “Joe has two daughters, and I am married to the older one,” explains Nachlis.

His educational path did not lead him toward the scrap industry. “I have a master’s degree in health/hospital administration,” he notes. “My master’s degree program required me to do residency, and I did that here in Indianapolis,” adds the Pennsylvania native.

After his residency was over, Nachlis stayed on with the hospital in Indianapolis as part of its staff. At this same time, in the late 1990s, it was clear that the decision-makers at his father-in-law’s company were aging. “Joe was in his early 60s, the general manager also was in his 60s, and Joe’s father was in his 80s and then 90s,” he recalls.

“Joe had mentioned in passing about me trying the scrap business,” he continues. “I decided to take a week’s vacation from my other job and spend time in the scrap yard. I felt from what I saw it was a much more dynamic environment than what I was doing in hospital administration,” says Nachlis, who adds that he presently has few regrets about making the career change back in 1998.

He says his work shifted from making long-range plans to reacting to circumstances that can change instantly. “There is no planning in this business,” he says. “You don’t know when you walk in in the morning what the markets will do, who is calling to sell, who is calling to buy or what operations challenges you’ll face. Every day is a different experience in the scrap industry. You have exposure to world economies and how events around the world can affect commodity markets wherever you are.”

|

By request Historically and by virtue of its prior cramped facility, J. Solotken & Co. Inc. focused on nonferrous metals processing and trading while maintaining only a minor presence in the ferrous sector. Moving into a roomy, modern plant in 2010, however, has allowed the Indianapolis-based firm to accept larger volumes of ferrous scrap. The company has been especially willing to do so when it comes as a response to customer requests. “We were not always as active in the ferrous business as we are today,” says J. Solotken & Co. Inc. President Brian Nachlis. “There were [formerly] industrial accounts here in Indiana where we would handle the nonferrous and someone else the ferrous,” he adds. The personal service and payment terms offered by J. Solotken & Co. Inc., as well as the perceived decline in those traits by some larger scrap companies, began yielding numerous requests made to the firm. “With consolidation and family companies being bought out, the service and the attention that some of these suppliers were getting started to lag,” Nachlis says. “They inquired with us whether we were capable of handling ferrous scrap. If it’s coming from an industrial source or even if it requires some basic processing, it was a fit that we could go in and handle their ferrous scrap—especially now in our larger building,” he continues. “Our volume as a company has greatly increased as we have become more active in the ferrous sector.” |

Although it may be hectic, Nachlis says that unlike planning a hospital project that may or may not ever come to fruition, he enjoys the tangible aspects of his work now. “Every day walking out of your office, whether you’ve had a good day or a bad day, you see very quick results from decisions you make in this business.”

Alpert says his son-in-law not only adapted to the change in pace but he also has embraced the core J. Solotken philosophy of maintaining personal relationships with customers on all sides of a business transaction.

Nachlis says he found this aspect of the scrap business among the most fulfilling. “In this business you build relationships with suppliers, consumers and the people you work with,” he comments.

Alpert and Nachlis cite relationship-building as a pivotal reason why J. Solotken & Co. Inc. has endured and thrived for a full century. “We believe we differentiate ourselves by the personal relationships we have with our buyers,” Nachlis says. “At our company we don’t have voice mail; you speak with an individual. People who do business with us know who they are doing business with. They are doing business not only with the company but the person at the company.”

Alpert expresses pride in his son-in-law’s ability to carry on this aspect of the family business not only with customers but also with employees. “He has nurtured great relationships with our employees. It has been wonderful to see him grow and be successful in developing our employees to be the best we’ve ever had,” he states.

Nachlis says the focus on employee relationships in turn helps J. Solotken & Co. Inc. maintain its close ties with customers. Many of the larger scrap companies operating in Indiana and adjacent states are now publicly traded and subject to high employee turnover, he says. “When you compare that to J. Solotken & Co. Inc., Joe’s been here 46 years, and I’ve been here 16 years. We do not have turnover in the key positions of our company, and we promote from within. Of our receptionists, one became a bookkeeper and another is selling scrap and doing logistics. There is consistency in our workforce—even the staff out in the warehouse,” he comments.

Another aspect not to be overlooked when maintaining strong customer relationships is payment terms, say Alpert and Nachlis. “We average net five days on payments,” Alpert says. “We’re going to pay you now. That’s one way we can differentiate ourselves form the competition.”

Mixing it up

For much of its recent history, it would have been accurate to describe J. Solotken & Co. Inc. as a nonferrous metals recycling firm.

The company’s early history, however, included a considerable amount of paper recycling activity (since discontinued), while more recently the company has become heavily involved in ferrous scrap recycling. (See the sidebar, “By Request,” on page 46.)

The emergence of Nachlis as the company’s administrative leader also has allowed Alpert to broaden J. Solotken & Co. Inc.’s reach into specialty and minor metals activities.

“As I saw the day-to-day things going so smoothly under Brian, I’ve had time to pursue unusual forms of scrap, like tantalum and kirksite [a die-cast zinc alloy], and find niches that larger competitors might not service,” Alpert says. “This is where I found my excitement: I find the source and then go find the market. I can only do that because the day-to-day nitty-gritty is being handled without me being required to participate,” he adds.

Nachlis says it has been a pleasure to watch Alpert work on that front. “Joe’s strength has always been in finding the suppliers and especially finding the markets,” Nachlis says. “He’s always reading every trade magazine—every word. Joe’s strength is his knowledge of high-temp alloys, brass alloys and other metals. He’s good at making sure we’re getting the highest value we can for our scrap.”

Alpert, who recalls hand sorting metals and working a hand-cranked Toledo scale under the tutelage of his father and his uncle Leo, is grateful that his son-in-law’s presence in the company has allowed him to obtain some distance from both the administrative and the operations aspects of the business.

“I tell people my biggest fear is I might wake up, because this is a dream,” he comments. “I’ve been in the business so many years, and it was always my hope to move into a modern facility. We have, and it wouldn’t have been possible without Brian coming forward as he did.”

By the numbers, the expansion amounts to a 58 percent increase in tonnage handled in 2013 compared with 2009 and a 145 percent increase compared with 2000.

Nachlis is confident that growth opportunities remain but is quick to comment that growth will be sought carefully and deliberately. “We’re a pretty conservative company, and we’re not looking to expand by acquisition, and we’re not necessarily looking to open up another location,” he states. “We seek calculated growth opportunities in areas where we think we can add value.”

Nachlis is confident that growth opportunities remain but is quick to comment that growth will be sought carefully and deliberately. “We’re a pretty conservative company, and we’re not looking to expand by acquisition, and we’re not necessarily looking to open up another location,” he states. “We seek calculated growth opportunities in areas where we think we can add value.”

As an example, Nachlis says, J. Solotken & Co. Inc. has added a wire chopping system. “We as a company were always having our wire tolled. We felt this was one area that would allow us to expand. We also do business with a lot of dealers by buying their scrap but not their insulated wire. The relationship is there and we can expand on it. It’s those kinds of opportunities we’ll pursue.”

As befits a company that emphasizes its relationships, Nachlis also attributes J. Solotken & Co. Inc.’s growth to the success of its customers. “Luckily a lot of the companies that we do business with have been fortunate enough to expand their businesses,” he says. “We have thus been on the receiving end of their success—their expansions and their growth.”

For Alpert, J. Solotken & Co. Inc.’s performance in the last several years has surpassed the expectations he had when he started out more than four decades ago, he says. “When I started 45 years ago, I had no expectations that the business could expand and excel to the level we are currently enjoying.”

The author is editor of Recycling Today and can be contacted at btaylor@gie.net.

Explore the December 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- RMDAS April figures show recycled steel price setback

- Steer World offers PEX plastic recycling machine

- New recycling grant program launches in Massachusetts

- Tire Recycling Foundation names executive director

- Dock 7 named 2025 Exporter of the Year at New Jersey International Trade Awards

- Waste Connections reports ‘better than expected’ Q1 results

- Commentary: How EPR is transforming the packaging industry

- Acerinox names new North American Stainless CEO