Two research scientists at Dow Inc. made an interesting presentation at a recent blow molding conference about the urgency of achieving a circular economy versus the high amount of energy used to reprocess plastic scrap. The presentation by Narayan Ramesh, Ph.D., and Sukaran S. Arora, Ph.D., at the Annual Blow Molding Conference last fall in Atlanta was sponsored by the Society of Plastics Engineers (SPE) Blow Molding Division.

The big picture is mitigating climate change. Reducing carbon emissions and achieving circularity help accomplish that goal. The global plastics industry contributes about 0.5 percent of overall emissions. Only a small percentage of plastics is recycled, so the Dow scientists said the plastics industry has more of a waste problem than an emissions problem.

Manufacturers of mechanical recycling equipment continually are pushing the envelope to make their machines smarter, faster and more efficient. Recyclers generally try to source plastic scrap from as close as possible to their plants, which saves money and reduces greenhouse gas emissions associated with transportation. While it is true that it takes a good deal of energy to clean, sort, melt and repelletize plastic so it can be used in another product, mechanical recycling is currently the best option for some plastics. Is it truly circular? Probably not, but there is not yet a better alternative.

Advanced recycling, where plastic is converted to chemical feedstocks, is the developing frontier, and virgin resin manufacturers are making big investments in new recycling operations. Advanced recycling techniques probably also fail the true circularity test based on the amount of energy they use. But this technology is still very much evolving, and it is not yet clear how efficient these plants will be in terms of greenhouse gas emissions.

Eastman Chemical Co. has announced a $1 billion investment to build a molecular recycling facility in France that will use the company’s methanolysis polyester renewal technology to convert polyester back into basic monomers to create virgin-quality resin. The proposed plant will have an annual capacity of 176,000 tons.

Eastman says molecular recycling is part of its strategy to decarbonize. It has deployed its technology in the U.S. for the past two years and has shown 20 percent to 50 percent lower greenhouse gas emissions than traditional virgin resin production. It says it expects to achieve 80 percent less greenhouse gas emissions in France.

Plastic recyclers have an interesting story to tell. For example, plastic containers generally have a smaller carbon footprint than glass or metal, even when made with 100 percent virgin plastic. Most consumers do not know this, so they silently accept it when someone says plastic is bad for the environment. But progress is being made.

Recycling is just one step on the circularity path, but it is an important step. Recyclers need to tell that story to everyone who will listen.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

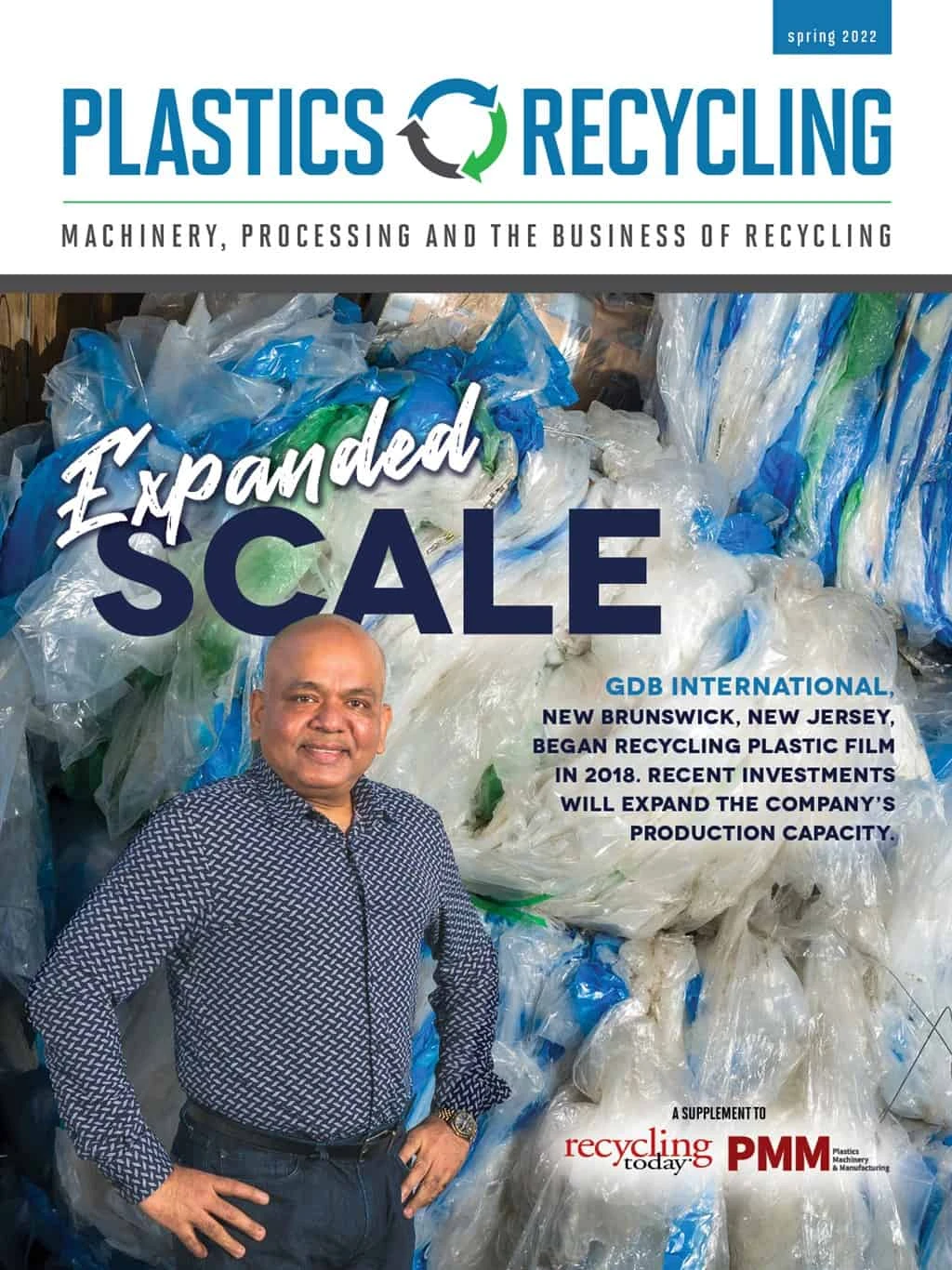

Explore the Spring 2022 Plastics Recycling Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Green Cubes unveils forklift battery line

- Rebar association points to trade turmoil

- LumiCup offers single-use plastic alternative

- European project yields recycled-content ABS

- ICM to host colocated events in Shanghai

- Astera runs into NIMBY concerns in Colorado

- ReMA opposes European efforts seeking export restrictions for recyclables

- Fresh Perspective: Raj Bagaria