LiuGong Machinery Co. Ltd. MH material handlers

Katy, Texas-based LiuGong North America, a subsidiary of Guangxi LiuGong Machinery Co. Ltd., has introduced its MH series of wheeled material handlers. The company says its MH40, MH40XD, MH50 and MH60 models, developed in collaboration with Rocky Mount, Virginia-based Jewell Machinery, are designed to meet the specific needs of the scrap recycling and forestry industries in North America. The line of material handlers:

- are powered by Cummings T-4 final engines and feature Kessler axles, Dana transmissions, Kawasaki hydraulics and Pierce fronts, with a 130-amp Hubbell controller and a 25-kilowatt-hour Baldor generator on the MH40 model

- are built for easy maintenance and include ground-level access to auto greasers to minimize downtime and maximize productivity

- prioritize operator comfort and efficiency with pilot-operated controls for precise handling and onboard diagnostics that allow operators to monitor hydraulic pressure from the cabin

- include a comprehensive three-year, 4,000-hour warranty on the entire machine

Visit www.liugongna.com for more information.

Volvo L110H and L120H wheel loaders

Sweden-based Volvo Construction Equipment, with North American headquarters in Shippensburg, Pennsylvania, has upgraded its L110H and L120H midsize wheel loaders to help increase uptime and convenience for operators and technicians. The upgraded wheel loaders:

- feature a new Volvo D8M 8-liter engine that offers 256 horsepower on the L110H and 272 horsepower on the L120H and automatically regenerates while working

- feature a new electric pump for priming the fuel system in the new engine, making the process quicker and more convenient than with the former manual pump

- have a new ignition strategy similar to Volvo articulated haulers, where the ignition key activates and powers the machine with no need to turn on the ground-level main switch at the start of every shift

- include lockout/tagout, making it easier to lock the battery disconnect switch in the off position and prevent an unwelcome energy release when performing maintenance

- comes with a new-generation Co-Pilot tablet with a larger, higher-resolution screen that can display load assist applications like onboard weighing, operator coaching and tire pressure monitoring

Visit www.volvoce.com for more information.

Werk-Brau Tiltrotators

Findlay, Ohio-based attachments producer Werk-Brau offers products that feature 360-degree Tiltrotator technology designed by Sweden-based Steelwrist. Werk-Brau, which makes attachments for excavators, mini excavators, backhoes, mini and full-size loaders, crawler loaders and skid steers, says the Tiltrotator technology:

- provides 360 degrees of endless rotation, with a 45-degree tilt angle

- allows operators to perform numerous tasks without repositioning their excavators

- features Steelwrist’s SQ sandwich-style coupler and auto lubrication for precise control and flexibility, which can significantly enhance user productivity

- is available to fit excavators from 2 tons to 33 tons, each with a low building height, high tilt angle and low weight for optimized digging geometry and fuel efficiency

- includes steel cast components designed to provide an optimal weight-to-strength relationship, availability of front pin hook or front pin lock designs and selective use of materials “with no weak weld seams” that are designed to make the devices compact and robust

Visit www.werk-brau.com for more information.

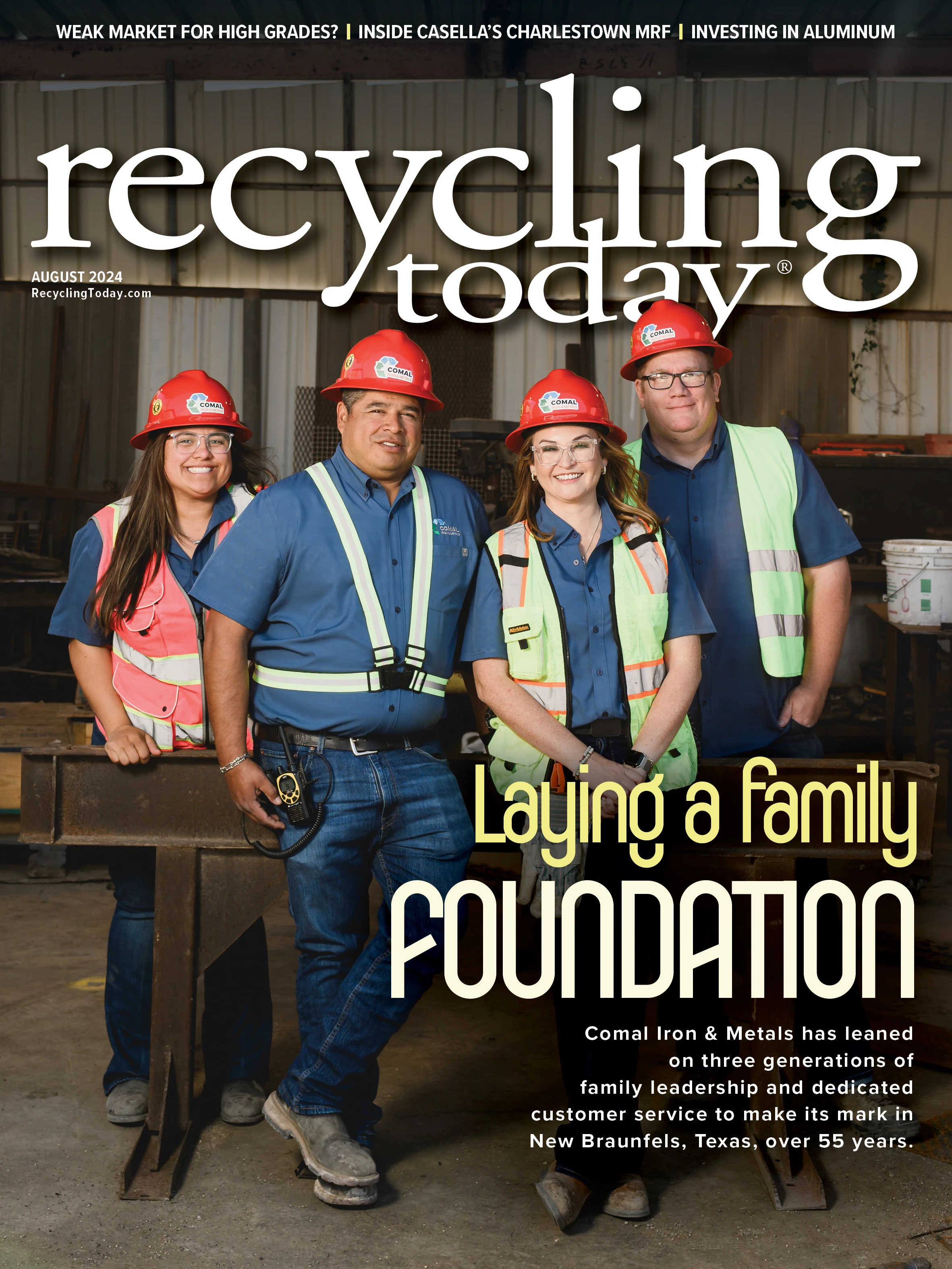

Explore the August 2024 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Lautenbach Recycling names business development manager

- Sebright Products partners with German waste management equipment company

- WasteExpo transitions to biennial format for enhanced experiences

- Study highlights progress, challenges in meeting PCR goals for packaging

- Washington legislature passes EPR bill

- PureCycle makes progress on use of PureFive resin in film trials

- New copper alloy achieves unprecedented high-temperature performance

- Gränges boosts profits and sales volume in Q1 2025