Matt Seaholm, 39, isn’t shying away from backlash against plastics. The new CEO of the Plastics Industry Association (PLASTICS) has a message he’s planning to amplify through the success stories of the organization’s members: “Plastic is an integral component of society at this point. Getting rid of it is not a viable option. Should we use it more wisely and more sustainably? Of course, we should.”

What are your priorities as CEO? We will be a stronger voice for the industry. In addition, we are going to invest in those advocacy capabilities. On the public policy front, I was vice president of government affairs before this. It all has a central theme at this point on behalf of the industry—sustainability.

In terms of sustainability, how do you plan to proceed? One of the things we’re hearing on a regular basis is that we can’t recycle our way out of this. It’s just false; it absolutely is possible. It’s a lot of work. It’s a lot of investment. But the industry is spending billions of dollars to build recycling technologies and capabilities. But we can’t do it alone. You’ve got the collection; you’ve got the sortation; consumers have to be a part of it. Put it all together, and we can get our recycling rate to the place where we want it to be. ... It’s our job to lead on that.

What sort of policies does PLASTICS support? First, you’ve got the funding mechanisms that need to be in place to fund recycling infrastructure improvements. A well-crafted extended producer responsibility (EPR) plan can work. Our industry has said we will accept a fee on our products to be able to fund the necessary recycling infrastructure. Unfortunately, a lot of the proposals we’ve seen are meant more to punish than ... [find] solutions. That’s where a lot of push-pull is happening, especially at the state level. Reasonable recycled-content requirements are another thing the industry can really get behind; you’ll recycle more if you’ve got a greater end market.

Additionally, advanced recycling is a key component of any success. One of the important things that we said to members of Congress was that the best thing they can do is not stifle innovation. The industry ... [is] putting a lot of effort into figuring out new technologies that get us to the scale we need.

What are the basic components of a well-crafted EPR policy? First and foremost, we’re not interested in just a tax on our products that ultimately goes to fund general revenue programs. We’re not interested in that because the purpose of the fee is to build the recycling infrastructure. In addition, the definition of “producer” is another important part of it. We see that sometimes it’s the manufacturer who gets attached to the definition of producer, when the manufacturer doesn’t have the necessary information to provide to the PRO [producer responsibility organization]. There’s a desire to stick it on the manufacturers, and that doesn’t necessarily make sense.

On top of [that] is control over the programs. We’ve seen some of these producer responsibility organizations who are really controlled by the state. If it’s just going to be an extension of a state agency, just call it what it is. If the responsibility is going to be placed on the producers, those who are part of the process of producing a product, ultimately using it, then put the mandate on us to achieve certain rates and dates, and say, “You’ve got to come up with a plan to do it.” We’re going to achieve greater success because it’s extended producer responsibility rather than just state programs.

What else, besides EPR? Maybe not the most exciting things in the world, but some better standards and definitions. We’re starting to see different definitions and standards being set from state to state, and it’s just not the way to do it. “Recyclable,” “recyclability,” even “compostable,” these are things that really should be decided and agreed upon.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

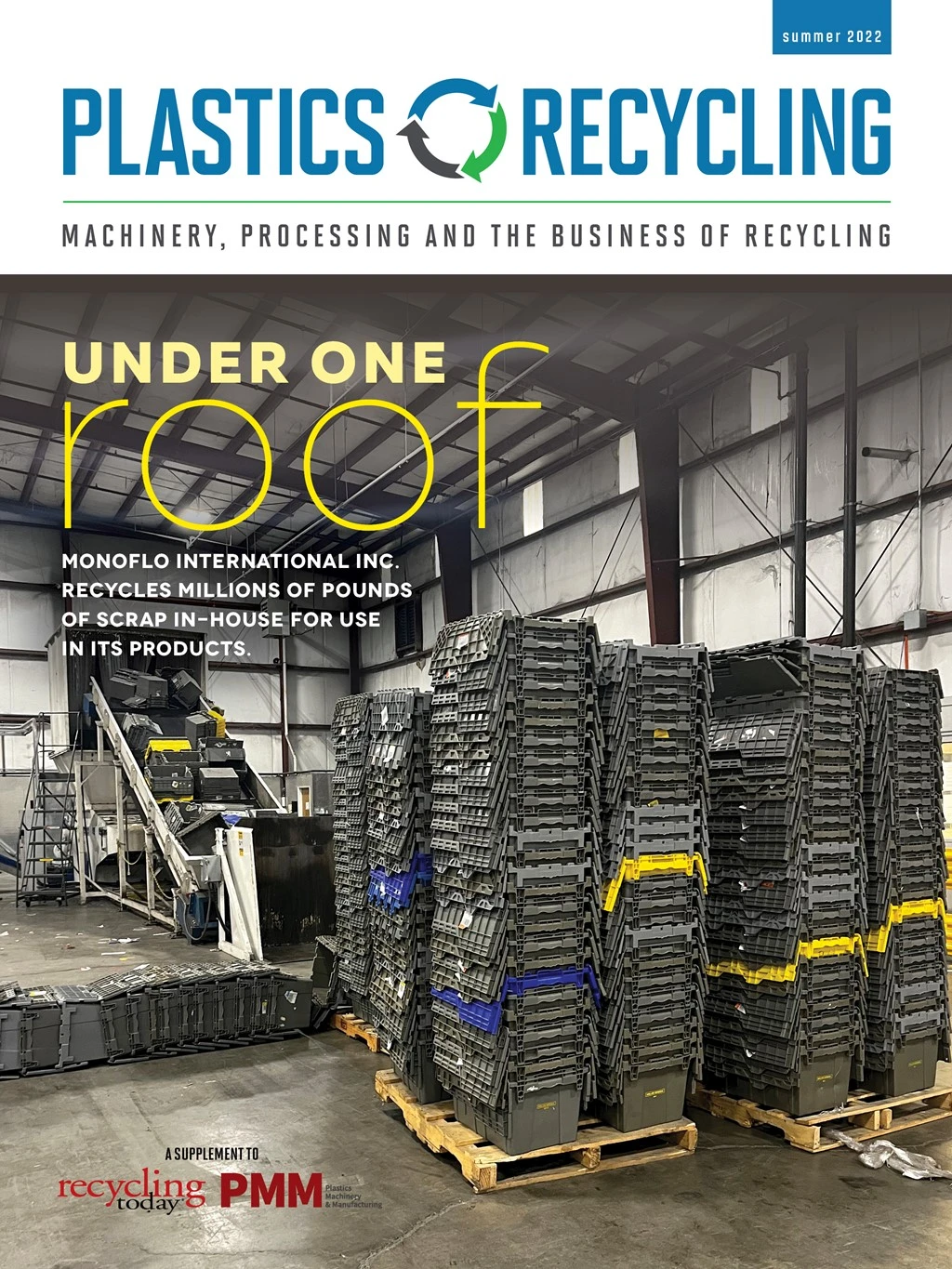

Explore the Summer 2022 Plastics Recycling Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Steel Dynamics nets $217 million on record shipments

- Massive Chinese steelmaking rebound recorded in March

- LME looks into sustainable metal pricing

- OnePlanet Solar Recycling closes $7M seed financing round

- AMCS launches AMCS Platform Spring 2025 update

- Cyclic Materials to build rare earth recycling facility in Mesa, Arizona

- Ecobat’s Seculene product earns recognition for flame-retardant properties

- IWS’ newest MRF is part of its broader strategy to modernize waste management infrastructure