Alan Schrob recently accepted the position of postconsumer resin (PCR) manager at Calgary, Alberta-based Nova Chemicals Corp. after previously serving as senior leader of market management for the manufacturer of chemicals and plastic resins.

In his new role, Schrob is responsible for developing new and existing business relationships to secure supply of mechanically recycled polyethylene (PE).

Recycling Today talked with Schrob about his transition to this new role and Nova’s outlook for 2022.

Q: What does your new position entail, and how will your previous position translate into your new role at Nova?

A: In my last role, I was responsible for designing and implementing strategies related to our customers and in the markets in which our goal is to be a leader in. So, if you can imagine ... there’s some 30 to 40 different markets in which you can place PE resins into, and Nova has chosen a subset of those markets to be a leader in. And so, we’ve aligned our organization, our technology and our product line against those markets.

My role previous to this current one was to lead the implementation of our leadership in those markets. That experience allows me to really understand what our customers need in terms of the kinds of products that they want [and] the kinds of applications that they use our products in. … As we move into creating a circular economy, understanding all of those [kinds] of requirements and needs [our customers have] is a really good alignment to what I’m going to be doing now, which really is about expanding Nova’s presence in mechanical recycling. … We’ll be providing and expanding our portfolio of linear-low-density and high-density PCR or applications to meet those objectives that all of the industry value chain participants have subscribed to.

Q: Why did Nova choose to focus on mechanically recycled PCR?

A: PCR for us will be a material that we’ll use in those markets. So, if you think about markets, it’s food packaging, it’s heavy-duty shipping sacks, it’s caps and closures, it’s rotational [molding applications] and all those different places in which you can put PE resins. So, the idea of choosing PCR is really to facilitate adding another tool to our toolbox to provide to those customers and those kinds of markets.

Q: What prompted the shift from virgin resins to securing mechanically recycled PCR?

A: Nova, as a virgin resin supplier, provides these kinds of products to our customers for use in a whole number of different applications. So, when you think about what we’ve already done, if you will, to facilitate a circular economy, the kinds of materials that we make, the kinds of application development we do, in a large part, goes to facilitating either making products more recyclable, downgauging or reducing the amount of plastics that are used in these certain different applications. When you think about what the next logical step would be, [it] is to provide mechanically recycled PCR to be used in those applications for all intents and purposes to eliminate or reduce the amount of plastic that’s going to landfill. It felt like a logical next step for us to incorporate a PCR product line to be able to provide a solution.

Q: The circular economy strategy seems to play significantly into your role at Nova. Can you expand on that?

A: If you go back a few years, when sustainability in the circular economy became very important for our value chain, Nova developed a fulsome strategy revolving around sustainability. It involved things like ESG [environmental, social and governance], greenhouse gas, all the normal kinds of sustainability strategy items that you would think about. And we layered into that that an important part of what we need to be able to deliver to our customers is postconsumer recycling.

What we decided was that one of the things that Nova needs to be able to do is to provide a postconsumer resin to our customers. And among other things, we need to be able to know how to use these resins, how to put them into applications, how to ensure that they deliver the kinds of performance and quality that our virgin resins have, so there was all of that as a part of the strategy. But a key component was [that] we need to be able to provide these materials to our customers.

We started doing that [in 2021]. We work with recyclers on a number of different dimensions. If you think about what we’re experts at, and you think about what recyclers are experts at, they’re generally different things. We have a core competency being able to produce virgin polyethylene and being able to work with our customers to put it into products and applications. Recyclers have a core competency in basically doing that process … which is collect materials, sort the materials and process them into pellets, which can be used in something else. So, when you marry those two kinds of expertise, it makes sense for us to collaborate across that value chain with mechanical recyclers to bring those products to market.

Q: How have you seen that collaboration develop?

A: Our role essentially is that we’re selling PCR products produced by, today, Revolution, and within the beginning parts of [this year] from [Merlin Plastics and Circulus], as well. So, we’ll have a full suite of these kinds of products that our recycling partners provide that we can now place into those applications and provide to our customers that really facilitate meeting the goals of the industry. So, we have the expertise of how to use these products, our recycling partners have the expertise to make them, and so it’s a very nice sort of collaboration where we can bridge the best of both of those and bring them to our customers.

Q: It seems Nova anticipates even more growth in this area in 2022.

A: When you look at the fact that I’ve been sort of newly named into this position, we really understand that it’s not nearly enough. But what we’ve done in 2021 was really pivotal for us in being able to start providing these mechanically recycled PCR products to our customers. But we plan for a significant portion of our sales over the next, call it decade, to be PCR. So [2022] is a really important year for us to continue to drive [toward] meeting that objective.

Q: What challenges have you encountered at Nova when it comes to mechanical recycling and securing PCR?

A: Some of the logistics issues that the whole industry has been facing, that’s been plaguing us as well in terms of being able to ensure we have enough material to put on the roads and on the railroads to be able to get to our customers.

I think, over the long run, what the industry is going to have to continue to rally around is having enough material to source to be able to produce PCR to put into these applications. And that requires everybody to work together.

For example, we need better collection, we need better sortation and then we need to process [better], otherwise the idea of meeting the industry’s [circularity] objectives will become more difficult.

… I think over the long term we have to make sure that we’re continually improving all components of that value chain from sortation to how they’re used in our customers’ and brands’ products.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

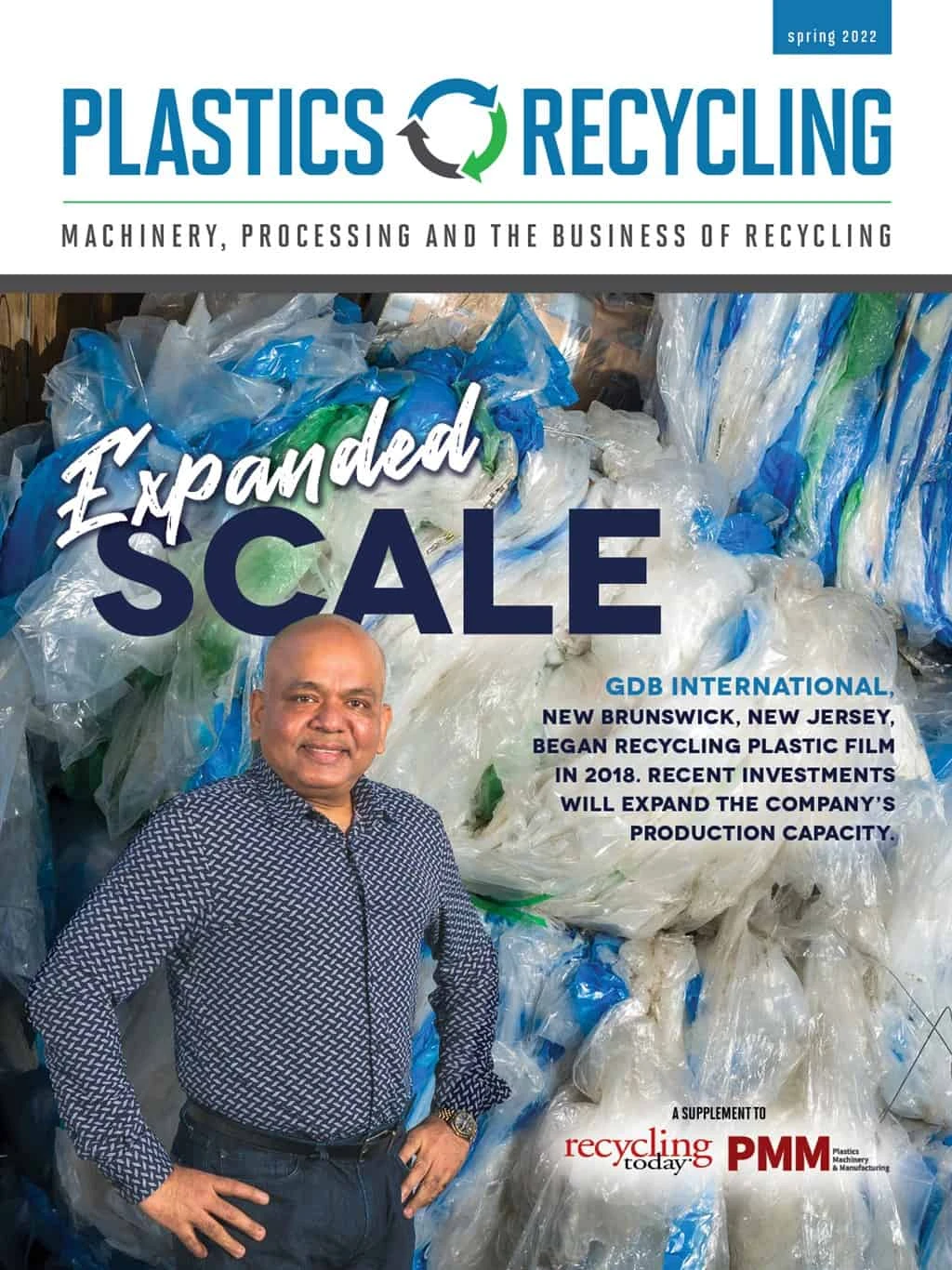

Explore the Spring 2022 Plastics Recycling Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Freepoint Eco-Systems receives $50M loan for plastics recycling facility

- PET thermoform recycling the focus of new NAPCOR white paper

- Steel Dynamics cites favorable conditions in Q1

- Hydro starts up construction in Spain

- Green Cubes unveils forklift battery line

- Rebar association points to trade turmoil

- LumiCup offers single-use plastic alternative

- European project yields recycled-content ABS