Secondary aluminum scrap demand and pricing continue to be weighed down by the semiconductor shortage affecting the automotive sector.

A nonferrous trader with a scrap processing company based in the Northeast says demand for secondary grades of scrap is not as strong as demand for primary grades. This has been the trend throughout much of 2021 as the automotive industry has had constraints imposed on its production in light of the semiconductor shortage, affecting its demand for cast aluminum products made from secondary aluminum.

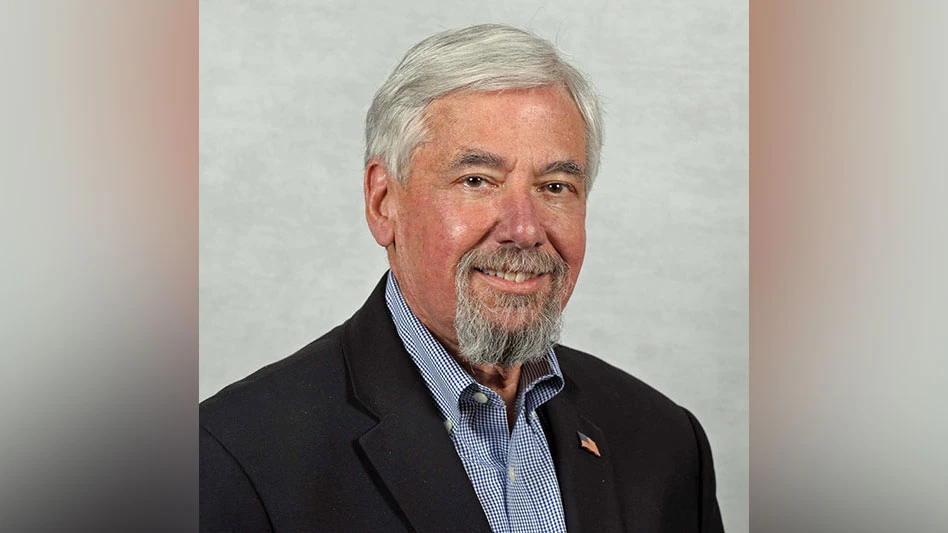

Colin Denihan, vice president of Wabash, Indiana-based Metal Source, which operates scrap yards and produces 356 aluminum sow and ingot, de-ox products and 380 aluminum sow and ingot, says demand has been consistent for the aluminum scrap grades his company procures and consumes: aluminum wheels, engines, old cast, turnings and foundry dross. He adds that the company is “pretty competitive” in terms of pricing.

Denihan says he sees spreads widening for secondary grades of aluminum scrap in the last quarter of the year in light of the ongoing chip shortage. “A lot of our contracts are taking the minimum. The spot market pricing isn’t as attractive based on the automotive demand.”

“Everyone’s eyes were too big a few months ago, so now the delivery windows are tight with tighter grading.” – a trader based in the Northeast says of aluminum scrap consumers

He says export demand for aluminum scrap is stronger than it has been in the last three months as of mid-September. “They need scrap,” Denihan says. “They are nervous with this price run. They are trying to source anything with silicon or that is a prime equivalent, not just secondary grades.”

In the domestic market, the contact based in the Northeast says, “UBC (used beverage can) pricing is great, but there are very few delivery appointments.

“Everyone’s eyes were too big a few months ago, so now the delivery windows are tight with tighter grading,” the trader says of aluminum scrap consumers. “I think it’s mostly a factor of capacity constraints and they bought too much fearing being left out of the market.”

He says export markets are still looking for red metals and aluminum grades that are difficult to move domestically. “It’s a boon for peddler yards,” the trader in the Northeast adds.

Nonferrous scrap generation has been ticking upward slowly, the trader says, though demolition activity is showing signs of softening. “Demo [scrap] is waning as we get closer to winter. It’s mostly seasonal around here.”

Material movement is hampered by the ongoing issues in the trucking sector, and high costs are affecting scrap processors’ profits.

“If you primarily rely on third-party carriers, you’re getting killed right now,” the trader says. He says it’s easier to absorb the high costs when shipping high-value copper or nickel/stainless scrap. “Aluminum, not so much. It hurts.”

Sponsored Content

Redefining Wire Processing Standards

In nonferrous wire and cable processing, SWEED balances proven performance with ongoing innovation. From standard systems to tailored solutions, we focus on efficient recovery and practical design. By continually refining our equipment and introducing new technology, we quietly shape the industry—one advancement at a time.

The trader adds that the number of dropped loads has increased while pricing has increased 50 percent over the last nine months.

Denihan says freight is a considerable factor for Metal Source when it comes to procuring metal. “Logistics has been a huge struggle for everybody I would say,” he adds.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the October 2021 Issue

Check out more from this issue and find your next story to read.